Aluminum Coil Sales Pittsburgh - Aluminum Roll 1050 Aluminum Alloy Coil O Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

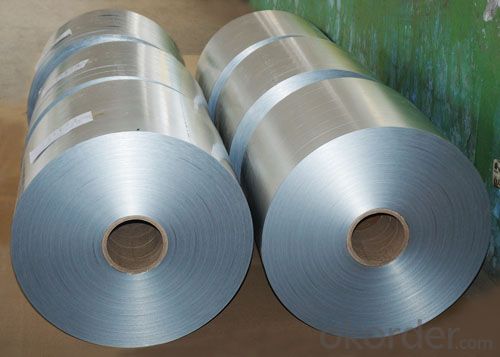

Aluminum Roll 1050 Aluminum Alloy Coil O Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: Other than alloys. I'm trying to think of a way I can make an aluminum knife that will hold an edge. One group of researches say they used 60 metric tons of force to realign the molecular structure and give the metal strength equal to steel. I don't have a 60 ton press aha. Would heat treatment plus 10 tons of pressure repeated have a similar affect?

- Aluminum bronze is used commercially to make non-sparking knives. Why try to reinvent the wheel? I'm trying to think of a way I can make an aluminum knife that will hold an edge. You can strengthen aluminum by either cold working or heat treating a suitable alloy, but it will never be anything close to a good steel knife. Would heat treatment plus 10 tons of pressure repeated have a similar affect? No. Assuming that you are talking about the article linked to below: - you would have to duplicate the alloy process, even then you could only make a small thin sheet. They used a heat treatable alloy. The process involves torsional strain under 60 metric tons per square centimeter compression. How big a press do you think you would need for a knife size blank? And remember, you have to apply torsional cold work while compressing it. -Their results ( 1 gPA YS 5% elongation in a very thin sheet) don't look that great compared to a good knife steel. Or a good titanium knife.

- Q: Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a lightweight and durable material that is commonly used in various industries, including the lighting industry. It offers excellent heat dissipation properties, making it suitable for fixtures that generate heat, such as LED lights. Additionally, aluminum coils can be easily shaped and molded into different designs, making them a versatile choice for lighting fixture production.

- Q: Are aluminum coils suitable for automotive heat shields?

- Indeed, automotive heat shields can indeed be made using aluminum coils. Aluminum, owing to its exceptional heat resistance and thermal conductivity characteristics, is extensively employed in the automotive sector. Its lightweight nature and remarkable strength-to-weight ratio render it a perfect option for heat shields. Through the utilization of aluminum coils, heat dissipation can be effectively achieved, thereby safeguarding delicate components from excessive heat exposure. Moreover, aluminum exhibits corrosion resistance, a vital attribute for automotive applications, given the exposure of heat shields to diverse environmental conditions. In conclusion, aluminum coils provide the essential properties and performance needed for automotive heat shields.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: What are the maximum operating temperatures for aluminum coils?

- The maximum operating temperatures for aluminum coils typically depend on the specific alloy used and the application they are being used in. However, in general, aluminum coils can withstand high temperatures without significant degradation or performance issues. For most common aluminum alloys, such as 3003 and 5052, the maximum operating temperature is around 300-400 degrees Fahrenheit (150-200 degrees Celsius). These temperatures are well within the range of most industrial and commercial applications, including HVAC systems, refrigeration units, and heat exchangers. There are also specialized aluminum alloys, such as 4004 and 4343, that are designed specifically for high-temperature applications. These alloys can withstand temperatures up to 550-650 degrees Fahrenheit (290-340 degrees Celsius) without significant loss of structural integrity or performance. It's worth noting that the maximum operating temperature may vary depending on factors such as the thickness of the coil, the heat transfer conditions, and the duration of exposure to high temperatures. Therefore, it is always advisable to consult the specific manufacturer's guidelines or conduct temperature tests to determine the safe operating limits for a particular aluminum coil in a specific application.

- Q: Are aluminum coils available in custom sizes?

- Yes, aluminum coils are available in custom sizes. Aluminum coils are versatile and can be manufactured to meet specific size requirements. This flexibility allows for a wide range of applications across various industries. Whether it's for HVAC systems, transportation, construction, or other purposes, aluminum coils can be custom-made to fit the specific needs of a project. Custom-sized aluminum coils ensure a perfect fit and optimal performance, offering greater efficiency and cost-effectiveness.

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are generally resistant to UV rays. Aluminum is a non-reactive metal, which means it does not easily corrode or react with other substances. This resistance to corrosion extends to UV rays as well. UV rays are a form of radiation emitted by the sun, and they can cause damage to various materials over time, including fading, discoloration, and degradation. However, aluminum is known for its ability to withstand UV rays without significant damage. This makes aluminum coils a suitable choice for outdoor applications where exposure to sunlight and UV rays is a concern, such as in air conditioning systems, refrigeration units, and solar panels. Additionally, aluminum coils can also be coated with protective finishes or paints to further enhance their resistance to UV rays and extend their lifespan.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q: I go on a trip once a year with a group of lets say 10 people, we go for 7 nights and consume on average approx 120 cans of beer each (throughout the week). We have a fire burning the whole time in a hole that we dig approx 1ft deep, then we dispose of each can in the fire and let them melt down never thinking about them again. That's approx 1,200 cans that melt in the one fire hole.Will the aluminum have an affect on the soil? does anyone know what sort of damage this can cause? and for what distance / area around the fire might be affected?The theory amongst the group is that cans do not hurt anything so that's why they take cans instead of glass.Thanks

- Aluminum is very reactive in air and will form a layer of aluminum oxide around the outside of any piece. This oxide layer is very stable which is why aluminum doesn't corrode. Since your block of aluminum will be totally oxidized being in a fire, it's inert and just going to sit in the hole for the foreseeable future. The burning paint might not be healthy to breath but that's about the only hazard. Most common soil is a mixture of aluminum, carbon and silica compounds anyways so you aren't even adding anything particularly exotic. Alternatively, you could bring along a couple fifths of whiskey. It's lighter and has less packaging so it's the environmentally friendly way to get drunk.

- Q: What are the different types of surface defects in aluminum coils?

- Aluminum coils can exhibit various surface defects, which can arise during manufacturing or as a result of handling and transportation. Common types of defects include scratches, pits, streaks, dents, oxidation, corrosion, and stains. Scratches are visible marks caused by contact with sharp objects and can range from superficial to deep grooves. Pits are small depressions caused by corrosion, wear and tear, or impurities in the aluminum material. Streaks are thin lines or bands caused by uneven coating application, improper cleaning, or contamination during manufacturing. Dents are deformations caused by impact or pressure during handling, stacking, or transportation. Oxidation refers to the formation of a thin layer of aluminum oxide on the surface, either naturally or due to exposure to moisture, air, or certain chemicals. Corrosion is the gradual deterioration of the surface due to chemical reactions with the environment, leading to discoloration, pitting, or the formation of powdery or flaky deposits. Stains are visible discolorations caused by water spots, oils, lubricants, or other contaminants. Manufacturers and suppliers implement quality control measures to minimize these defects and ensure that the coils meet the required standards and specifications. It is important to consider the severity and impact of these defects on the performance and appearance of the final product.

Send your message to us

Aluminum Coil Sales Pittsburgh - Aluminum Roll 1050 Aluminum Alloy Coil O Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords