Aluminum Bendable Strips for Aluminum Sheet in Truck Body with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

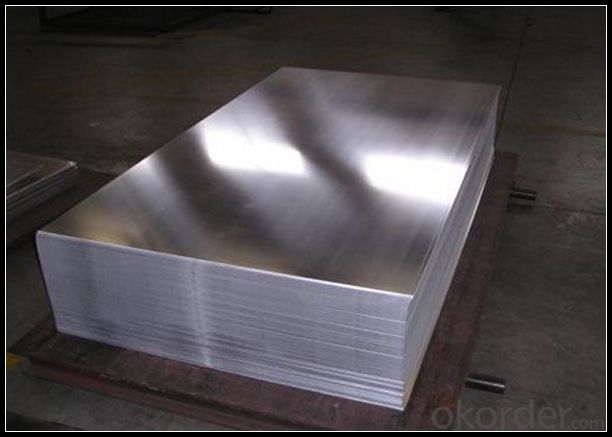

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a comparison of the cost of aluminum strips with other materials.

- <p>The cost of aluminum strips compared to other materials can vary significantly depending on the specific material being compared. Generally, aluminum is considered an economical choice due to its low cost, availability, and recyclability. It is less expensive than many metals such as stainless steel, copper, and titanium. However, when compared to plastics or some composite materials, aluminum might be more costly. The cost also depends on factors like the current market price of aluminum, the thickness and width of the strip, and the quality of the aluminum. For precise cost comparisons, it's best to consult current market prices and specific product specifications.</p>

- Q: Are aluminum strips suitable for manufacturing automotive components?

- <p>Yes, aluminum strips are commonly used for automotive parts due to their lightweight, high strength, and corrosion resistance. They are utilized in various components such as engine parts, body panels, and suspension systems to reduce weight and improve fuel efficiency. Additionally, aluminum's recyclability makes it an environmentally friendly choice for the automotive industry.</p>

- Q: What types of aluminum are more cost-effective for specific applications?

- <p>Yes, there are different types of aluminum alloys that offer varying degrees of cost-effectiveness depending on the application. For instance, 1100 series aluminum, which is 99% pure, is the most cost-effective due to its low alloying content but has limited strength. On the other hand, 6000 series alloys, like 6061, are stronger and more durable, making them ideal for structural applications but slightly more expensive. The choice depends on factors like strength, corrosion resistance, and weight requirements, which can influence the cost-effectiveness of an aluminum alloy for a specific use.</p>

- Q: What constitutes the primary substance of aluminum strips?

- <p>Aluminum strips are primarily made from aluminum, a lightweight and malleable metal known for its high conductivity and resistance to corrosion. They are typically composed of pure aluminum or aluminum alloys, which may include elements such as copper, magnesium, manganese, or silicon to enhance specific properties like strength or durability. These strips are widely used in various industries due to their versatility and the metal's beneficial characteristics.</p>

- Q: What are the potential health risks related to the use of aluminum foil?

- <p>While aluminum foil is widely used in cooking and food storage, there is limited evidence to suggest significant health risks. Some studies have linked aluminum exposure to neurological conditions like Alzheimer's, but the connection is not conclusive. The body does not absorb significant amounts of aluminum from foil, especially when used properly. However, it's important to avoid wrapping acidic or highly acidic foods in aluminum foil, as this could potentially lead to increased aluminum leaching. Overall, using aluminum foil in moderation and following proper food handling practices can minimize any potential risks.</p>

- Q: What are the characteristics of the 5052 aluminum strip?

- Al Mg anti rust aluminum, high fatigue strength, plasticity in high resistance to corrosion, heat treatment can not enhance, contact welding and welding of atomic hydrogen, argon arc welding has the tendency of crystal crack, alloy and semi Xinghua hardening state of machinability is better in the cold.

- Q: This question asks for a method to determine the weight of a specific length of aluminum strip.

- <p>To calculate the weight of a certain length of aluminum strip, you need to know the strip's length, width, thickness, and the density of aluminum. The density of aluminum is approximately 2700 kg/m鲁. The formula to calculate the weight is: Weight = (Length 脳 Width 脳 Thickness 脳 Density) / 1000. Convert all measurements to consistent units (SI units are preferred). For example, if you have a strip that is 1 meter long, 0.01 meters wide, and 0.001 meters thick, the weight would be calculated as follows: (1 脳 0.01 脳 0.001 脳 2700) / 1000 = 0.027 kg.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

- Q: This question asks about the impact of aluminum strips on the thermal insulation properties of a building.

- <p>Aluminum strips can significantly affect the insulation of a building by reflecting heat and light, reducing the amount of heat that is absorbed by the building's structure. This reflective property helps to keep the interior cooler in summer and can reduce the load on air conditioning systems. However, if not properly insulated, aluminum strips can also lead to heat loss in winter, as they can reflect heat back out of the building. Proper installation with insulation materials can maximize the benefits of aluminum strips in maintaining a comfortable indoor temperature while conserving energy.</p>

- Q: The user is asking whether they should hire a professional to install aluminum strip products or if they can do it themselves.

- <p>Whether to hire a professional or do it yourself depends on your experience and comfort level with DIY projects. If you are skilled in construction or have experience with similar installations, you may be able to install aluminum strip products yourself. However, if you lack the necessary skills or are unsure about the process, hiring a professional installer is recommended. Professionals have the expertise to ensure a proper and secure installation, which can save you time and potential complications down the line. Additionally, they can handle any unexpected issues that may arise during the installation process.</p>

Send your message to us

Aluminum Bendable Strips for Aluminum Sheet in Truck Body with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords