High-Quality Aluminum Tube at Competitive Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Tube Description:

Aluminium Tube is the comprehensive combination of photogravure printing, phototype surface printing,hot stamping,screen printing, exposed aluminum process, VM highlight technology is innovatively used, which will realize the hollowed out, gradient, pearl light, highlight and other printing effects on the tube surface, and bring the brand-new printing effect experience to the cosmetic packaging.

The usage of aluminium tube is packaging for pharmaceutical . cosmetic (hair dye cream, personal care cream, burn ointment,eye cream, hand cream, hotel toothpaste etc.) . Shoeshine cream . food (chocolate . mustard . jam.animal food etc . )

2.Main Features of the Aluminium Tube:

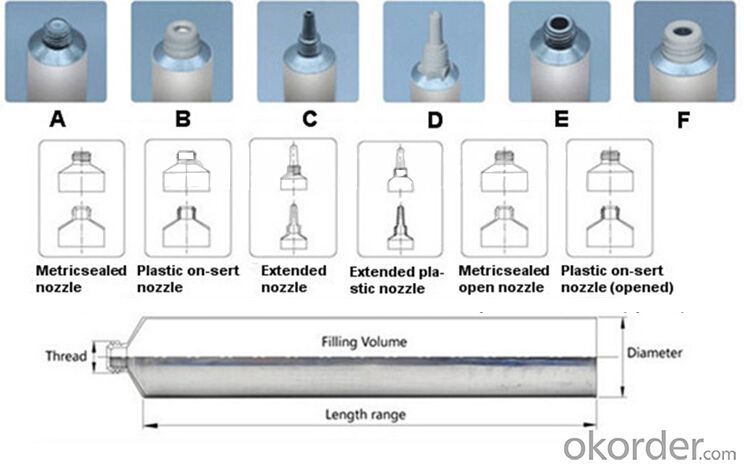

Open, Closed(Sealed) or Elongated

99.7% Pure & Brand New Aluminum Cap

Ultraviolet sterilization

High Quality and Competitive Price

3. Aluminium Tube Images

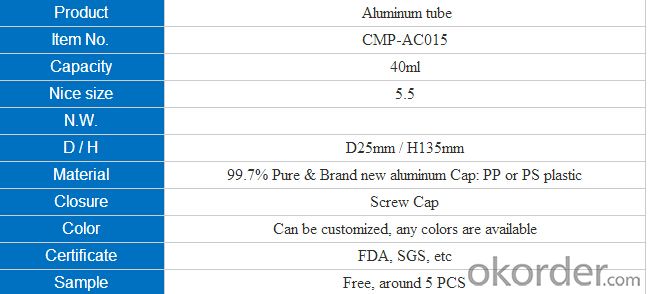

4. Aluminium Tube Specification:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Our company is a state-owned company.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it possible to create jewelry using pure aluminum?

- <p>Yes, pure aluminum can be used to make jewelry, but it's not commonly used for fine jewelry due to its lower value and potential for oxidation. While it is lightweight and affordable, it lacks the luster and durability of precious metals like gold, silver, or platinum. Aluminum can tarnish and may cause allergic reactions in some individuals. It is more commonly used in costume jewelry or for specific designs where its properties are advantageous.</p>

- Q: This question asks whether it is safe to use aluminum cookware for pregnant women or individuals with health conditions.

- <p>While aluminum cookware is generally safe for most people, there are concerns about its potential health effects. Aluminum has been linked to cognitive issues and Alzheimer's disease, although the evidence is not conclusive. For pregnant women and those with health conditions, it is advisable to err on the side of caution. Opt for cookware made from stainless steel, cast iron, or non-stick materials without aluminum. If you must use aluminum cookware, avoid acidic or alkaline foods and ensure the cookware is not scratched, as this can increase aluminum leaching into food.</p>

- Q: What are the positive environmental impacts of utilizing recycled aluminum over newly produced aluminum?

- <p>Using recycled aluminum has several environmental benefits. It conserves natural resources by reducing the need for bauxite mining, which is the primary source of aluminum. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which can lead to a substantial reduction in greenhouse gas emissions. Additionally, recycling aluminum helps in reducing landfill waste, as it diverts used aluminum products from landfills. Moreover, it decreases the environmental impact associated with the production process, such as water pollution and habitat destruction. Overall, recycling aluminum is a more sustainable practice that contributes to a lower carbon footprint and a healthier environment.</p>

- Q: Is it possible to construct vehicles using aluminum?

- <p>Yes, aluminum can be used to make cars. It is known for its lightweight, high strength, and corrosion resistance, which are desirable properties in automotive manufacturing. Aluminum alloys are commonly used in car bodies, engines, and other components to reduce weight, improve fuel efficiency, and enhance performance. Additionally, its recyclability makes it an environmentally friendly choice for vehicle production.</p>

- Q: This question asks about the methods to determine the safety of a specific brand's aluminum products.

- <p>To determine if a particular brand of aluminum products is safe to use, one should look for certifications and standards compliance. Check if the brand has certifications such as ISO 9001 for quality management systems or specific safety certifications relevant to aluminum products. Look for compliance with safety standards like ANSI, ASTM, or EN standards. Additionally, research customer reviews and testimonials, and consider third-party lab testing results. It's also important to inquire about the manufacturing process to ensure it adheres to environmental and health safety regulations. Lastly, consult with industry experts or regulatory bodies for their assessment of the brand's safety practices.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: This question asks about the impact of aluminum on human health when it is ingested through food packaged in aluminum containers.

- <p>Aluminum is a common element found in the environment, and it is naturally present in small amounts in many foods. When food is packaged in aluminum, there is a possibility of trace amounts of aluminum leaching into the food, particularly in acidic foods. While the human body can handle small amounts of aluminum without harm, excessive intake over a long period may lead to potential health concerns. Aluminum has been associated with neurological disorders, although the evidence is not conclusive. It's important to note that the risk is generally low, as the body does not absorb a significant amount of aluminum from food or packaging. However, it is always recommended to follow food safety guidelines and use packaging materials that are deemed safe for food contact.</p>

- Q: Is it possible to employ methods for recycling aluminum that are less harmful to the environment?

- <p>Yes, there are less harmful methods for recycling aluminum. One such method is mechanical recycling, which involves shredding and melting aluminum without the need for chemical processing, reducing environmental impact. Additionally, promoting a circular economy by designing products for disassembly and recycling can minimize waste. Encouraging consumer participation in recycling programs and improving recycling technology also contribute to more sustainable aluminum recycling practices.</p>

- Q: This question asks about the steps involved in preparing aluminum foil for use in food packaging.

- <p>Aluminum foil for food packaging is processed through several steps. First, aluminum ingots are melted and then rolled into thin sheets. The sheets are cleaned to remove any impurities and coated with a thin layer of food-grade protective coating to prevent any chemical reactions with the food. Next, the sheets are cut into rolls or sheets of standard sizes. The aluminum foil is then inspected for quality, ensuring it is free from defects and safe for food contact. Finally, it is packaged and shipped to manufacturers who use it to wrap or package food products.</p>

Send your message to us

High-Quality Aluminum Tube at Competitive Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords