Customized Painted Aluminum Coil - Aluminium Roofing Sheet/Coil in Competitive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

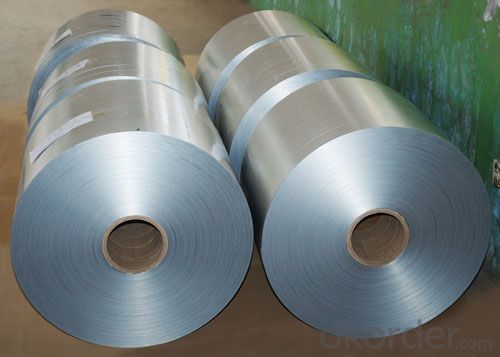

Aluminium Roofing Sheet/Coil In Competitive

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be used in the production of consumer goods?

- Yes, aluminum coils can be used in the production of consumer goods. Aluminum is a versatile material that is lightweight, durable, and corrosion-resistant, making it suitable for a wide range of applications such as cans, packaging, appliances, and automotive parts. The flexibility and formability of aluminum coils allow manufacturers to create various consumer products efficiently and cost-effectively.

- Q: Explain the distinctions among various welding equipment used specifically for joining aluminum coils.

- <p>Different types of welding equipment for aluminum coils include Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Resistance Welding (RW). GTAW, also known as TIG welding, uses a non-consumable tungsten electrode and produces high-quality welds with minimal distortion. GMAW, or MIG welding, uses a continuous wire feed as the electrode and is faster but may not be as precise. Resistance Welding involves using electrical current to heat the metals at the joint, which is quick and efficient but not suitable for all aluminum alloys. Each method has its advantages and is chosen based on factors like weld quality, speed, and the specific aluminum alloy being welded.</p>

- Q: Explain the relationship between aluminum coil and aluminum alloy in a few sentences.

- <p>Aluminum coil and aluminum alloy are related in that aluminum coil can be made from aluminum alloy. An aluminum alloy is a material composed of aluminum and other metallic or non-metallic elements, which are mixed to enhance its properties. Aluminum coils are long, rolled sheets of aluminum that can be made from various types of aluminum, including alloys. The use of an alloy allows for the creation of aluminum coils with specific characteristics, such as increased strength, corrosion resistance, or formability, depending on the application requirements. Thus, aluminum coils are often manufactured from aluminum alloys to meet the demands of diverse industries.</p>

- Q: Are aluminum coils suitable for roofing applications?

- Yes, aluminum coils are suitable for roofing applications. Aluminum is a lightweight and durable material that offers many advantages for roofing projects. It has excellent corrosion resistance, which is important for protecting roofs from weather elements such as rain, snow, and UV radiation. Aluminum is also non-combustible, making it a safe choice for roofing applications. Additionally, aluminum coils are highly malleable, allowing for easy shaping and installation on various roof designs. They are also available in a wide range of colors and finishes, providing aesthetic options for different architectural styles. Overall, aluminum coils are a popular choice for roofing due to their durability, versatility, and aesthetic appeal.

- Q: Can aluminum coils be used for automotive heat shields?

- Yes, aluminum coils can be used for automotive heat shields. Aluminum is a lightweight and durable material that has excellent heat resistance properties, making it suitable for use in automotive heat shields. Its ability to dissipate heat efficiently helps protect sensitive components from excessive heat, ensuring optimal performance and durability in vehicles.

- Q: When you open an aluminum beverage can, do particles of aluminum get into the drink?

- It depends on the type of drink inside the can. Aluminium is a metal in the group three of the periodic table of elements so it has three positive charges when ionized although it has metallic bond between its nucleus and its electrons. If the drink contains too much acid such as HCl with a high concentration the acid may react with the aluminium can if it is not coated or galvanized. Although it may not physically break off for the particles to enter the drink, it may dissolute in the kind of substance inside the drink.

- Q: What are the different surface textures available for aluminum coils?

- There are several different surface textures available for aluminum coils, each with its own unique characteristics and applications. 1. Smooth: Smooth surface texture is the most basic and common type of finish for aluminum coils. It has a sleek and polished appearance, making it suitable for a wide range of applications such as architectural cladding, signage, and consumer electronics. 2. Stucco: Stucco texture features a raised pattern resembling small pebbles. This texture is achieved by embossing the surface of the aluminum coil, providing enhanced durability and resistance to scratches and dents. It is often used in applications where a more robust and decorative finish is desired, such as roofing, wall panels, and decorative trim. 3. Diamond: Diamond texture features a diamond-shaped pattern embossed onto the surface of the aluminum coil. This texture not only enhances the aesthetic appeal but also provides additional traction and slip resistance, making it ideal for applications such as flooring, stairs, and ramps. 4. Brushed: Brushed texture is achieved by mechanically brushing the surface of the aluminum coil, creating a linear pattern. This finish gives the aluminum a distinctive, satin-like appearance, making it popular for architectural applications such as interior wall cladding, furniture, and decorative elements. 5. Hammered: Hammered texture is achieved by hammering the surface of the aluminum coil, resulting in a unique and irregular pattern. This texture provides a rustic, handcrafted look, making it suitable for applications such as decorative accents, light fixtures, and furniture. 6. Perforated: Perforated texture involves creating a pattern of small holes or perforations on the surface of the aluminum coil. This texture allows for increased airflow, light transmission, and sound absorption, making it commonly used in applications such as ventilation systems, acoustic panels, and decorative screens. These are just a few examples of the various surface textures available for aluminum coils. The choice of texture depends on the specific requirements of the application, including aesthetics, functionality, and durability.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils go through numerous quality control tests to ensure their reliability and performance. One primary test is the dimensional inspection, where the coils' physical dimensions are measured and compared to the manufacturer's specifications. This helps identify any discrepancies in length, width, thickness, or diameter. Another critical test is the visual inspection, where the coils are thoroughly examined for surface defects like scratches, dents, or discoloration. This visual examination is crucial to ensuring that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests measure the coils' resistance to breaking under tension, determining their durability and strength. In addition, hardness tests assess the coils' resistance to indentation or deformation. The hardness values are compared to predetermined standards to verify if the coils meet the necessary criteria. Corrosion resistance testing is also conducted to assess the coils' ability to withstand corrosion over time. This test exposes the coils to harsh environments or corrosive substances, which is crucial as aluminum is often used in applications that may involve contact with corrosive elements. Electrical conductivity tests ensure the proper functioning of the coils in electrical applications. Conductivity is measured and compared to the required specifications to guarantee that the coils possess the desired electrical characteristics. Additionally, depending on the specific requirements of the aluminum coils, other tests like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed. Overall, these comprehensive quality control tests enable manufacturers to ensure that aluminum coils meet necessary standards, ensuring their quality, performance, and reliability in various applications.

- Q: Some manufactures (Kia, Hundai) use Iron blockswhileOther manufactures (Nissan, Chevy, ect.) use Aluminum blocks*****Is the point of using Iron blocks to increase long-term durability or temperature endurance??ORIs the use of Iron blocks simply an older, simpler technology (as compared to using Aluminum), the manufacture of which costs less money??And you would think that Aluminum weight savings would transer to better MPG, but the Kia gets very comparable mileage anyway.Thank you

- The latter points were right. Iron blocks are heavier, although much cheaper to make. Aluminum ones are significantly lighter and handle heat better, but it is a bit more expensive to make them.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- There is a significant savings - especially in electricity - about 90% less energy used to recycle aluminum than it takes to smelt ore and process it into useable aluminum.

Send your message to us

Customized Painted Aluminum Coil - Aluminium Roofing Sheet/Coil in Competitive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords