Painted Aluminum Coil Sheet Sds for Cold Rolling Re-Passing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

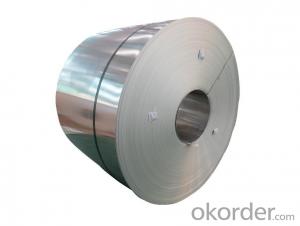

1.Structure of Aluminium Coils for Cold Rolling Re-Passing

Aluminium Coils for Cold Rolling Re-Passing is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Cold Rolling Re-Passing

a.We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

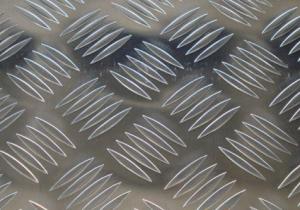

3. Image of Aluminium Coils for Cold Rolling Re-Passing

4. Product Specification of Aluminium Coils for Cold Rolling Re-Passing

| ALLOY | TEMPER | THICKNESS | COATING THICKNESS | WEIGHT |

| AA1050 | H14 | 3-8MM | 22-25 MICRONS | 3-5 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: Are aluminum coils compatible with different welding methods?

- Different welding methods can be used with aluminum coils. Aluminum is a versatile metal that can be welded using techniques like gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW). These methods are commonly used for welding aluminum coils because they produce high-quality welds. GTAW, also known as TIG welding, is particularly suitable for aluminum. It allows for precise control of heat input and produces excellent weld quality. TIG welding uses a non-consumable tungsten electrode and an inert gas like argon to protect the weld zone from contamination. GMAW, also known as MIG welding, is a faster process that uses a consumable wire electrode and a shielding gas to protect the weld pool. It is widely used in industrial applications due to its efficiency and ease of use. In addition to TIG and MIG welding, other methods like laser welding and friction stir welding can also be used for aluminum coils, depending on specific requirements. Proper preparation is crucial for successful welds. Cleaning and surface treatment of the aluminum coils are important to remove contaminants or oxide layers that could affect the welding process. Overall, different welding methods can be used with aluminum coils, and the choice depends on factors like desired weld quality, production requirements, and available skills and equipment.

- Q: Is it safe or practical to utilize aluminum coils in kitchen settings?

- <p>Aluminum coils can be used in the kitchen, but with certain considerations. They are often used in cookware due to their excellent heat conductivity, which allows for even heating. However, there are concerns about aluminum leaching into food, especially at high temperatures or in acidic environments, which could potentially have health implications. It's recommended to use aluminum cookware with a protective coating or to opt for cookware made from other materials like stainless steel or cast iron if there are health concerns. Always check the manufacturer's guidelines for safe usage and cleaning to ensure longevity and safety.</p>

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: What is the acceptable range of temperatures for aluminum coils in terms of their functionality and durability?

- <p>The temperature range for aluminum coils can vary depending on the specific application and alloy type. Generally, aluminum coils can operate effectively within a range of -200掳F to 500掳F (-129掳C to 260掳C). For most industrial applications, the working temperature is between -40掳F to 300掳F (-40掳C to 150掳C). However, it's important to consult the manufacturer's specifications for the exact temperature limits of a particular aluminum coil, as these can differ based on the alloy and intended use.</p>

- Q: Why there is always impression and indentation on the backup roller of aluminum coil rolling mill with 4 rollers.

- It is either the external or the bearing problem in designing and installing.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: What is the cost-effectiveness of using aluminum coils compared to other materials?

- The cost-effectiveness of using aluminum coils compared to other materials is generally favorable. Aluminum coils are lightweight, durable, and corrosion-resistant, which reduces maintenance and replacement costs. They also have excellent heat transfer properties, leading to energy efficiency and cost savings in heating and cooling systems. Additionally, aluminum is a widely available and recyclable material, lowering the overall cost and environmental impact.

- Q: Can aluminum coils be used in extreme temperature conditions?

- Yes, aluminum coils can be used in extreme temperature conditions. Aluminum has a high thermal conductivity and is resistant to corrosion, making it suitable for various temperature extremes. Additionally, aluminum's low melting point allows it to withstand high temperatures without deforming or losing its structural integrity.

- Q: How do aluminum coils perform in high humidity environments?

- Aluminum coils perform well in high humidity environments due to their inherent resistance to corrosion. Unlike many other metals, such as iron or steel, aluminum does not rust when exposed to moisture. This makes it a suitable choice for applications where high humidity is a concern, such as air conditioning systems or refrigeration units. The corrosion resistance of aluminum is primarily due to the formation of a thin layer of aluminum oxide on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against further oxidation, preventing the metal from deteriorating even in humid conditions. Moreover, the lightweight nature of aluminum allows for better heat transfer and energy efficiency in cooling systems. This property makes aluminum coils a popular choice as heat exchangers, as they can effectively transfer heat from the air or fluid passing through them. Additionally, aluminum coils are typically coated with a protective layer or treated with a corrosion-resistant coating to further enhance their performance in high humidity environments. These coatings provide an extra layer of protection against moisture and other corrosive elements, ensuring the longevity and reliability of the coils. In summary, aluminum coils are highly suitable for high humidity environments due to their resistance to corrosion and their efficient heat transfer properties. The combination of these factors makes them a reliable choice for various applications where moisture is a concern.

Send your message to us

Painted Aluminum Coil Sheet Sds for Cold Rolling Re-Passing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords