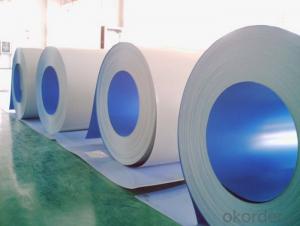

Aluminium Ceiling Panels Made in China - Color Coated Aluminum Coil AA1060 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

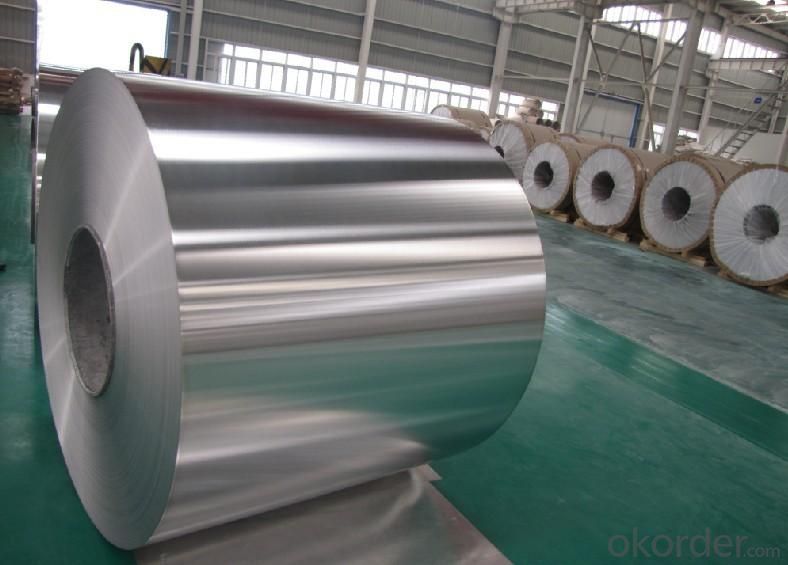

Color Coated Aluminum Coil AA1060 Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

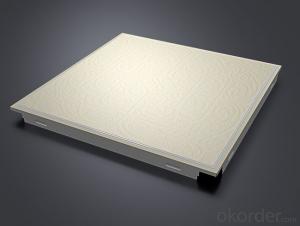

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: Interior decoration often use the strip of aluminum slabs have any specifications of the profile. Often the market is how long and how long to sell? Thank you! The The Usually the kitchen, bathroom, corridor ceiling with.

- Good black 1.5mm thick

- Q: Living room wall is rough wall putty, And part of the rough wall is outside the concrete + 1cm around the cement mortar, and some parts of the gas brick + 1cm outside the cement mortar , Now want to own ceiling, the difficulty is how to install the edge of the wall in the living room wall, rely on glue is not assured, this situation how to do?

- Aluminum-plastic plate Construction process: keel layout and elastic line → installation and leveling keel → installation of aluminum-plastic plate → trim sealing. ?1), the elastic line: to determine the elevation control line and keel layout line, if the ceiling has a variable height, the corresponding part of the variable section should be determined, and then along the elevation line fixed angle aluminum. ?2), to determine the keel position line: According to the size of aluminum-plastic panels and ceiling Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: What is the connection between the ceiling and the gypsum board?

- With stainless steel bar! If not with the button! But I suggest you still look good with stainless steel bar

- Q: My home to prepare the kitchen bathroom ceiling, to see the brand Aopu. But there are three kinds of film, spray and roll. Spray (the boss said also known as convex plate), gloss does not shine, according to no silhouette. There is a kind of roller, feeling like a printed on the color. These two are not shady, when the boss said that the film for a long time to rise from the layer, the best roll. I do not know, which professionals help me to answer, the best details of the point. Thank you

- Indeed, the film is more layers of skin, the skin is not finished, Or with other plates, we have done in the ceiling company, Recommend a called Ji Yang, in the local or a little famous,

- Q: Aluminum buckle plate aluminum plate wholesale price is how much

- Home and the use of aluminum slab plate thickness is generally 0.6mm and 0.8mm. Because the thickness of the aluminum plate is the best cost-effective, fully able to meet the load strength. If the thickness of thickening, not only a waste of resources, but also increased the consumer's unnecessary economic burden. And even some good brand, due to the use of aluminum material is very good, the thickness of only 0.45mm. Therefore, consumers in the purchase of aluminum plate, can not just judge the quality of sheet metal plate, the need for consumers is clear that the plate material is to determine the quality of aluminum standard plate, good aluminum toughness and strength appropriate, Recycled aluminum is often hard, but tough but poor.

- Q: How much is the price of an inch? Pack material

- Expensive more than 600 of a square, the specific brand is imported.

- Q: Do you want to use the top angle of the ceiling?

- Used to look better.

- Q: Yuba size of the general size of the size, and how to install the aluminum buckle hanging on the top of the

- Yuba open hole for the 300 * 300, there are Yuba openings for 300 * 400 or so. There are some differences between the requirements and methods of the reserved mounting ports depending on the different gussets: 1.300 * 300 or 300 * 600 aluminum plate hanging ceiling: stay a 300 * 300 buckle plate position can not be installed. 2. Striped aluminum bar, it is best to install the buckle plate when the size of the opening of the Yuba, in the installation of the buckle when leaving a good installation hole in the hanging on the preparation of two than the ceiling of the main keel span more solid Of the wood, do install Yuba use.

- Q: My bathroom in the bathroom on the ceiling of the pipes are leaking, want to remove the aluminum ceiling to see, but how can not open. Will this aluminum bar plate into the ceiling how to disassemble? Thank you!

- The first to use the first toilet to remove the other hand can buckle down

- Q: What are the requirements for designing a ceiling? Note the arrangement of the main and sub keylones and hanging bars and their size requirements

- 1. function 2. beautiful 3. practical 4. economy

Send your message to us

Aluminium Ceiling Panels Made in China - Color Coated Aluminum Coil AA1060 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords