Aluminum Ceiling Tiles with Goods Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: Aluminum Ceiling Tiles

Material: Aluminum sheet

Thickness: 0.45-1.0mm

System: Metric or British System

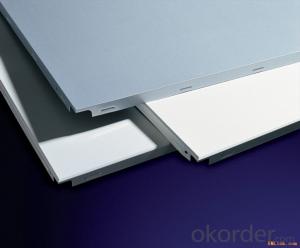

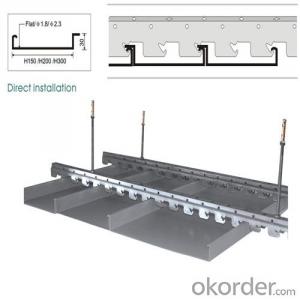

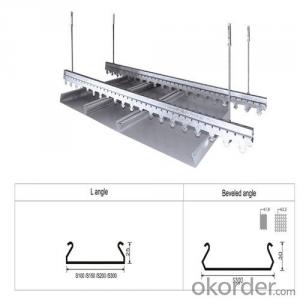

Model: Clip in, Lay in, Lay on

Edge height: 8mm, 10mm, 18mm

Surface: Powder coating, Pre-paint

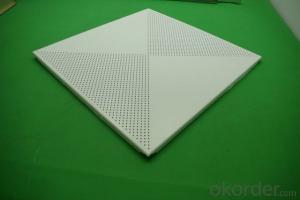

Perforation: Perf. 1.8mm, 2.3mm

NRC: 0.5~0.65

CAC: 30~40

Fire proof: B1

Function: Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Sound-Absorbing, Soundproof, Waterproof

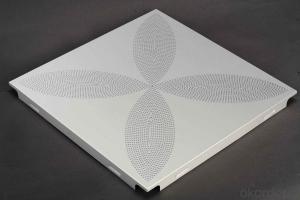

Feature: Artistic Ceilings, Integrated Ceilings, Perforated Ceilings

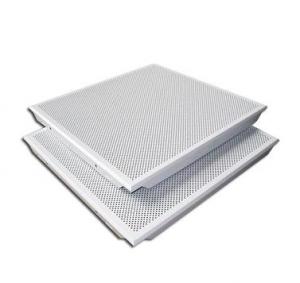

EASY PLENUM ACCESS

The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

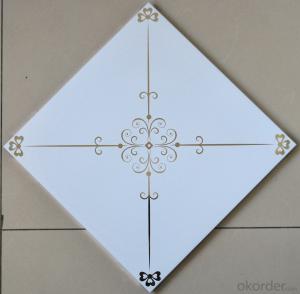

DESIGN FLEXIBILITY

Aluminum ceiling panel appearance provides interesting possibilities for spatial room designing.

The ceiling panel show different style pattern and shape, which engage you match your design.

A range of colors and finishes is standard available and special colors upon request.

DURABILITY

Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel 0.5 mm coil, finished with a polyester paint to provide a long, low maintenance life. The coating is stove-enamelled in a continuous coil coating process ensuring uniform coating thickness and absolute adhesion.

PRODUCT CHARACTERISTIC

1) Surface smoothness and easy cleaning ;

2) Flexible suspension system makes each ceiling tile easily installed and disconnected;

3) Easy to match lamps or other ceiling parts;

4) Surface color can be stable for 10 years by indoor use;

5) Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect.

- Q: What is the balcony ceiling hanging? Lycra board or sauna board? What kind of long life?

- See where you are hanging. The kitchen or the bathroom is the aluminum plate

- Q: These plates are very similar in the name, but has been indispensable, I lack of knowledge Oh, what professional people to help answer! Thank you so much!

- Aluminum perforated plates are usually used in large-scale building rain and wall, the thickness can be based on design requirements and layout span length processing.

- Q: The company is to do the aluminum alloy ceiling, is the first to buy aluminum back to the factory, do the shape, and then take the outside to spray the surface of the oil. Aluminum is how much money to buy back a ton, on the outside called someone else processing fuel injection Is how much money a square as we count, we sold to the customer is the number of a square to count, I ask this, how do I calculate the cost of it? Our company's product cost is not what is the kind, is based on the requirements of customers to do.

- And then can be collected into the cost of manufacturing costs allocated to the comprehensive calculation of the cost.

- Q: Engineering ceiling aluminum buckle plate 10 brand is tooling, not integrated ceiling

- Tooling ceiling aluminum plate 10 brands: West Meilun, Ou Bai, Lianxing, Tianyuan, Odyssey, Phil, France lion dragon, Kang Hao, the good, Badisi. Which in front of several relatively more famous than the other.

- Q: Aluminum buckle ceiling ceiling labor costs how much

- Aluminum plate also has a grade, generally not with the film of more than 30 yuan / square meter, with the end of the film should also be more than 60 yuan / square meter, the installation of 15 yuan / square meter, 0.6MM thickness. On the grade Fumo film even a good installation of more than 100 yuan / square meters above, 0.8MM thickness.

- Q: Aluminum buckle ceiling ceiling area is how to count

- If you calculate the area of a piece of gusset, such as 30 cm long, 30 cm wide aluminum gusset plate, an area of 0.3 m * 0.3 m = 0.09 square meters

- Q: What is an aluminum buckle? What place to use it, and gypsum board is different

- Often said that the aluminum plate is used to the kitchen and the bathroom ceiling, the specifications are mainly 300 * 300, a lot of color, commonly used in white and silver, matching accessories are light steel keel and paint corners;

- Q: Gypsum board smallpox is what things? Easy to use? With aluminum ceiling than how? Which is good.

- Home furnishings gypsum board, kitchen / Wei can use gypsum board, aluminum-plastic plate, aluminum plate, buckle board, sound-absorbing panels, grille; tooling with gypsum board or sound-absorbing panels or grille ceiling

- Q: If they say that the anti-oil strong nano-drawing does not change color in the end what is good? Please answer experts! Brushed the drawing of the nano is the nano of it

- It is recommended that your home kitchen with nano-white buckle plate, the surface of the nano-sheet is treated with nano-paint, waterproof and anti-oil change! And the oil stained above the words are also easier to clean! Our company is professional to do integration The ceiling!

- Q: How to handle between two different levels of aluminum slabs

- First ceiling to the dragon skeleton, the above is the main keel, the main keel hanging under the board of the vice keel, the main keel plus vice keel total of at least 5CM height space

Send your message to us

Aluminum Ceiling Tiles with Goods Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords