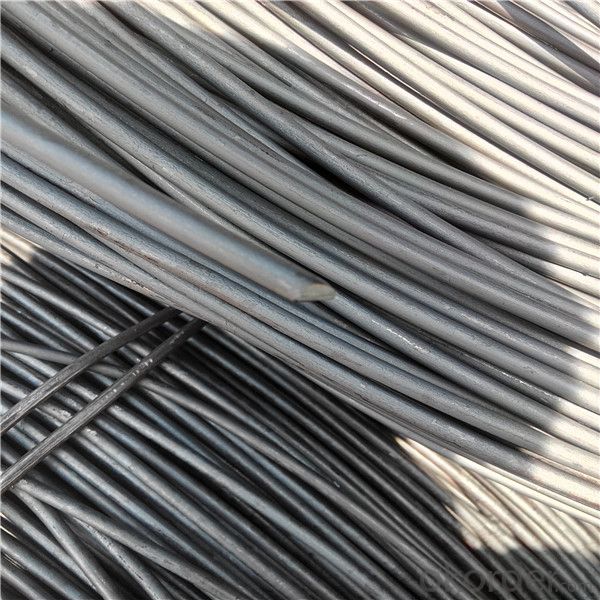

Steel wire rod prices in coil hot rolled for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 13256 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make for wire mesh.

Wire rod is a rolled alloy or nonalloy steel product, produced from a semi (e.g. bloom) and having a round, rectangular

or other cross-section. Particularly fine cross-sections may be achieved by subsequent cold forming (drawing). Wire

rod is wound into coils and transported in this form.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is steel wire rod used in the manufacturing of wire for agricultural fences?

- The production of wire for agricultural fences heavily relies on steel wire rod, which acts as the primary material. This raw material undergoes several procedures to convert it into a robust and long-lasting wire suitable for agricultural fencing purposes. To start, the steel wire rod is typically composed of high-quality carbon steel, chosen for its exceptional strength and resilience. This specific material can endure harsh outdoor conditions and resist corrosion, ensuring a prolonged lifespan for the agricultural fence. The manufacturing process commences with the introduction of the steel wire rod into a wire drawing machine. This machine gradually reduces the rod's diameter while elongating its length by pulling it through a series of dies. This process enhances the wire's tensile strength and flexibility, making it easier to handle during installation. Following the wire drawing procedure, the wire undergoes further processing to attain the desired characteristics for agricultural fencing. It may be subjected to a galvanization process, wherein a protective layer of zinc is applied to prevent rust and corrosion. Galvanized wire is particularly suitable for agricultural fences due to its increased durability and longevity, even in environments with high moisture levels. Alternatively, the wire can be coated with PVC or other polymer materials to provide additional protection against corrosion and improve visibility. Coated wires are commonly employed in agricultural fences to enhance their visibility, facilitating easier monitoring of livestock for farmers. Once the wire has been processed and coated, it is wound onto spools or reels, ready for distribution and installation. The wire is typically available in various gauges or thicknesses, allowing farmers to select the appropriate wire diameter based on the intended use and the type of animals they aim to confine. In conclusion, steel wire rod plays a vital role in the production of wire for agricultural fences. Through processes like wire drawing, galvanization, and coating, the steel wire rod is transformed into a durable and corrosion-resistant wire capable of withstanding the demanding conditions found in agricultural environments.

- Q: What are the different types of steel wire rod surface defect monitoring systems?

- There are various types of steel wire rod surface defect monitoring systems available in the market. Some common ones include laser scanners, optical inspection systems, electromagnetic systems, ultrasonic systems, and thermal imaging systems. These systems use different technologies to detect and monitor surface defects such as cracks, scratches, and irregularities in steel wire rods, ensuring product quality and integrity.

- Q: How is steel wire rod used in the manufacturing of wire mesh for filtration?

- Steel wire rod is used in the manufacturing of wire mesh for filtration as it serves as the raw material for producing the wire mesh. The steel wire rod is first drawn into thin wire strands, which are then woven or welded together to form the mesh structure. This mesh provides the necessary strength, durability, and flexibility required for filtration applications, such as removing impurities or separating particles in various industries like water treatment, automotive, and aerospace.

- Q: Can steel wire rod be used for welding applications?

- Yes, steel wire rod can be used for welding applications. It is commonly used as a filler material in welding processes such as MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. The steel wire rod provides a stable and consistent filler material, ensuring strong and reliable welds.

- Q: What are the common production processes for tungsten-coated steel wire rod?

- The common production processes for tungsten-coated steel wire rod include wire drawing, cleaning and degreasing, tungsten coating, and heat treatment.

- Q: What are the common applications of low alloy and oil tempered steel wire rod?

- Some common applications of low alloy and oil tempered steel wire rod include automotive components, construction materials, wire ropes, springs, and cables. These types of steel wire rod offer enhanced strength, durability, and resistance to corrosion, making them suitable for various industries where high-performance materials are required.

- Q: What are the safety precautions to be taken while working with steel wire rod?

- When working with steel wire rods, there are several safety precautions that should be taken to minimize the risk of accidents or injuries. These include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety glasses, gloves, and steel-toed boots to protect yourself from potential hazards. In some cases, a hard hat may also be necessary. 2. Training: Ensure that all workers are properly trained on the safe handling and use of steel wire rods. This includes understanding the potential hazards, safe operating procedures, and emergency protocols. 3. Handling and storage: When handling steel wire rods, use proper lifting techniques and equipment to avoid strains or injuries. Store the rods in a designated area, away from walkways or high traffic areas, to prevent tripping or falling hazards. 4. Inspection: Regularly inspect steel wire rods for any defects, such as sharp edges, rust, or damage, as these can pose a safety risk. If any defects are found, replace the rods or repair them before further use. 5. Secure the work area: Ensure that the work area is clear of clutter, debris, or any other potential tripping hazards. Keep the floor dry and clean to prevent slips and falls while working with steel wire rods. 6. Use proper tools and equipment: Use appropriate tools and equipment for cutting, bending, or shaping steel wire rods. Ensure that the tools are in good working condition and are used correctly to prevent accidents. 7. Fire safety: Steel wire rods can generate sparks when cut or welded, so it is important to have fire prevention measures in place. Ensure that fire extinguishers are readily available in the work area and that workers are trained on how to use them. 8. Communication: Establish clear communication channels between workers to ensure that everyone is aware of the work being done and any potential hazards. Use appropriate signage or warning labels to indicate areas where steel wire rods are being used or stored. By following these safety precautions, the risk of accidents or injuries while working with steel wire rods can be significantly reduced, ensuring a safe working environment for all.

- Q: What are the different surface lubricants used for steel wire rod?

- Some common surface lubricants used for steel wire rod include oil-based lubricants, water-based lubricants, and dry lubricants. These lubricants help reduce friction during wire drawing or other manufacturing processes, improving the wire's surface finish and preventing damage or breakage.

- Q: What are the different types of steel wire rod annealing atmospheres?

- There are several different types of steel wire rod annealing atmospheres that can be used depending on the desired outcome and specific requirements of the process. These atmospheres can vary in terms of the gases used and the conditions maintained during annealing. 1. Nitrogen Atmosphere: Nitrogen gas is commonly used in steel wire rod annealing processes. It is an inert gas that helps to protect the material from oxidation and decarburization. Nitrogen atmosphere creates a stable environment for annealing, ensuring consistent and controlled heat treatment. 2. Hydrogen Atmosphere: Hydrogen gas is another commonly used annealing atmosphere for steel wire rods. Hydrogen helps to minimize surface oxidation and can also aid in the removal of any surface contaminants or impurities. It promotes a clean and bright surface finish on the wire rod. 3. Vacuum Atmosphere: Vacuum annealing involves creating a low-pressure environment by removing air and other gases from the annealing chamber. This atmosphere prevents oxidation and allows for precise control over the annealing process. Vacuum annealing is often used for high-quality wire rods that require minimal surface defects and improved mechanical properties. 4. Inert Gas Mixtures: In some cases, a mixture of inert gases such as nitrogen and hydrogen may be used as an annealing atmosphere. This combination can provide the benefits of both gases, such as protection against oxidation and impurity removal. The specific mixture and ratios are determined based on the desired outcome and material requirements. 5. Controlled Atmosphere Furnaces: Controlled atmosphere furnaces allow for precise regulation of the annealing atmosphere by continuously monitoring and adjusting the gas composition. This enables the optimization of annealing conditions to achieve desired material properties and surface finishes. It is important to note that the choice of annealing atmosphere depends on the specific steel composition, desired properties, and end-use application of the wire rod. By carefully selecting the appropriate atmosphere, steel wire rods can undergo a controlled heat treatment process that enhances their mechanical properties, surface quality, and overall performance.

Send your message to us

Steel wire rod prices in coil hot rolled for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 13256 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords