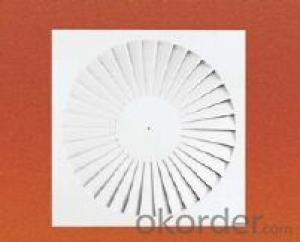

air condition vent mold Exhaust Air Valve

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description Air Condition Vent Mold Exhaust Air Valve for Construction or building

Air condition vent mold Exhaust Air Valve Is Engineered polymer construction, Three-way deflection,Traditional styling,Integral multi-shutter damper with easy to use damper handle For heating or cooling applications

Specifications of Air Condition Vent Mold Exhaust Air Valve for Construction or building

Exhaust Air Valve

Made of Galvanized Steel

exhaust air valve

Size 80, 100, 125, 160, 200mm

Removable core, with collar

Exhaust Air Valve

Material: Galvanized Steel

Finish: White powder coated

Size: 80mm, 100mm, 125mm, 160mm, 200mm

Removable core, with collar

For ceiling air supplying

Easy installation, and good performance

Packaging Detail: Standard export packing ,Your requirment accept.

Delivery Detail: 3-5 weeks

Advantage of Air Condition Vent Mold Exhaust Air Valve for Construction or building:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Feature of Air Condition Vent Mold Exhaust Air Valve for Construction or building

Engineering capabilities include:

1.Parts design.

2.R&D products.

3.Prototype design and production assembly.

4.Reputable design software used for all design work.

5.Hot runner design.

6.Cold runner design.

7.Fast automatice remould design.

8.Mold design with a team of experienced specialists.

Process of our company :

1.Quote competitive price according customer detail requirement.

2.Sign agreement.

3.Customer T/T deposit to us to start to design mould.

4.Send mould drawing to customer for confirmation.

5.Mould design confirmed and start to make mould.

6.Make mould trial during tooling time (which we get agreement with customer)

7.Send mould trial sample to customer for inspection.or customer come to our factory to inspect mould personally.

8.Customer T/T balance to us after mould confirmed.

9.Deliver mould after get balance.

Application of Air Diffusing Grille for Construction or building :

It is mostly used on the sidewall outlet type air distribution. We always export to supermarket to USA ,CHILE ETC. For heating or cooling applications.

FAQ :

1.What is the air grille?

It is made of plastic (ABS PVC,PP PE)or steel metal ,aluminum steel by mould. It could be used for sidewall ,outletype air distribution, heating or cooling applications.

2.what kind of grille we have ?

We have ABS /PP/ PVC Plastic Air Diffusing Grille, aluminum swirl air diffusers, floor register, return air grille , wooden register ,plastic air grille, aluminum air grille, baseboard registers, celling side way registers, plastic air vent, blades dampers, etc .

3.what is the application of our grilles?

It could be used for sidewall ,outletype air distribution, heating or cooling applications.

4. what kinds of design we have ?

Please check our catalogue or website for reference. Or we could make design as your ideas . We have professional technical team . they could make what you imagine.

- Q: The air-conditioning compressor is stuck. Is there any way to repair it?

- When necessary the appropriate starting capacitor capacity compressor for the specifications of a compressor can be normal to try to start up, and can be used with a screwdriver on the reverse way of trying to solve the compressor body.

- Q: What are the parts of the outdoor unit?

- The indoor machine comprises a heat exchange copper tube, a fan and an electric component

- Q: What is the purpose of a two-stage compression refrigeration cycle?

- The traditional air conditioning system can only achieve the lowest heat at minus 7 degrees Celsius environment itself, and adopting the two-stage inverter air conditioner double stage compressor can be achieved in the limit condition minus 30 DEG C under strong heating

- Q: What are the air compressors for?

- The air force: the traditional pneumatic tools, drilling machine, pneumatic, pneumatic wrench, pneumatic sandblasting

- Q: What is the working principle of the BOG compressor?

- General BOG compressor uses oil-free lubrication reciprocating compressor, the working principle is the same as the ordinary reciprocating compressor. The difference is that the inlet of the BOG compressor is low temperature gas, so the first stage cylinder block, piston and so on must be able to withstand low temperature, and also to prevent freezing

- Q: What is the cause of the overload of the air conditioning compressor?

- Dust on the outside condenser can be cleaned, and the heat insulation cotton wrapped on the compressor can be removed

- Q: What is the working principle of the compressor?

- A driven fluid machine that promotes low-pressure gas as a high-pressure gas; the heart of a refrigeration system. It is of low temperature and low pressure refrigerant gas suction pipe from the suction, through the operation of the motor drives the piston to compress it after high temperature and high pressure refrigerant gas discharge pipe to the exhaust, to provide power for the refrigeration cycle, so as to realize the compression and condensation (exothermic), expansion and evaporation (endothermic) refrigeration cycle

- Q: What is the working principle of the condenser?

- Single stage vapor compression refrigeration system, is composed of four basic components of the refrigeration compressor, a condenser, a throttling valve and an evaporator, between them with pipe connected to form a closed system, the refrigerant in the system continuously circulating flow, change, heat exchange with the outside world.

- Q: What is the Basic accessories for air conditioners?

- Sight glass,throttle valve,Compressor, evaporator, condenser and expansion valve

- Q: How many types of drive are there in an air conditioner compressor?

- Screw refrigeration compressor has the characteristics of small size, light weight, easy maintenance and so on. The special mirror bed for screw rotors, especially the introduction of grinding machines, improves the machining accuracy and machining efficiency of the key parts, so that the performance of the screw compressor is effectively improved

Send your message to us

air condition vent mold Exhaust Air Valve

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords