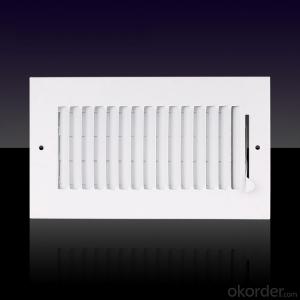

PVC vent grill mould air condition vent mold

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Packaging Detail: | Standard export packing ,Your requirment accept. |

| Delivery Detail: | 3-5 weeks |

Specifications

beautiful outlooking

good quality

Easy to install

competitive price

short delivery time

Plastic injection mould/mold plastic garden tool mould

| vent grill Mould | |

| Brand | Fangheng Mould |

| Mould material | P20,etc. |

| Cavity | single |

| Runner | cold |

| plastic material | PP |

| Mould life | more than 500,000 |

| Delivery time | 50 days |

| Design software | CAD,UG,PROE,CATIA,CIMATRON,etc. |

| Machine | CNC machine |

| Packaging | wooden case or as requested |

Advantage:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Engineering capabilities include:

1.Parts design.

2.R&D products.

3.Prototype design and production assembly.

4.Reputable design software used for all design work.

5.Hot runner design.

6.Cold runner design.

7.Fast automatice remould design.

8.Mold design with a team of experienced specialists.

Process:

1.Quote competitive price according customer detail requirement.

2.Sign agreement.

3.Customer T/T deposit to us to start to design mould.

4.Send mould drawing to customer for confirmation.

5.Mould design confirmed and start to make mould.

6.Make mould trial during tooling time (which we get agreement with customer)

7.Send mould trial sample to customer for inspection.or customer come to our factory to inspect mould personally.

8.Customer T/T balance to us after mould confirmed.

9.Deliver mould after get balance.

- Q: What are the parts of the outdoor unit?

- The indoor machine comprises a heat exchange copper tube, a fan and an electric component

- Q: What are the air compressors for?

- Air jet loom with compressed air blowing weft to replace the shuttle

- Q: What are the risk factors of condensers?

- Combustible components are mainly acetylene and other hydrocarbons, acetylene is the most dangerous, the solubility in liquid oxygen is very low (5.6 * 10-6mg/L), it is easy to precipitate in solid state and cause explosion.

- Q: What is the working principle of a two stage compressor?

- Condense it to the condensing pressure PK and drain into the condenser. In this way, the levels of pressure ratio is moderate, because after intermediate cooling, and can make the compressor power consumption is reduced, the reliability and economy are improved

- Q: What is the working principle of the compressor?

- Compressor mainly through the motor through the refrigerant from the gas compression into liquid

- Q: How to analyze air conditioning parts?

- The refrigerant operates in the sealed pipe between the parts and components, and carries, absorbs and releases heat so as to ensure the temperature of the indoor air can be adjusted. Ventilation system: fan and fan motors and ventilation ducts constitute the main part of the air conditioning ventilation system

- Q: What are the parts of an automobile air conditioner?

- The action of the compressor is to maintain the refrigerant circulating in the system, and improve the refrigerant gas pressure and temperature for gaseous refrigerant is condensed in the condenser into liquid and external heat expansion valve; the effect is to reduce the pressure of the liquid refrigerant through the throttling effect, convenient liquid, evaporation of the refrigerant into gas to absorb heat

- Q: What are the technical parameters of the compressor?

- The volume efficiency of a compressor is the ratio of the actual gas flow to the theoretical gas flow

- Q: How to repair air conditioning compressor?

- Check the compressor does not start trouble, such as the bottom of the capacitor drum, remove the capacitor, the bottom placed in the plane, such as standing instability, about rocking, then the compressor capacitor must be damaged, can be replaced directly

- Q: What are the types of condensers?

- The condenser is often used for the condensation of the two steam at the end of the multi effect evaporator to ensure the vacuum of the final effect evaporator

Send your message to us

PVC vent grill mould air condition vent mold

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords