Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Color Coated Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification:

Name | Color Coated Aluminum Coil | |

Brand | CMAX | |

Alloy | 1100,1235,3003,3004,3005,3105,5005,5052,8011 | |

Thickness | 0.2mm~200mm | |

Width | 40mm -1500mm | |

MOQ | 5T | |

Coating finish | PVDF,POLYESTER,NANO,BRUSHED | |

Color | As to code RAL | |

Surface | Embossed,Mill Finish,Coated | |

Gloss | 10-90%(EN ISO-2813:1994) | |

Total coating thick | PVDF 25 micron | |

Polyester 18micron(EN ISO-2360:1995) | ||

Coating hardness | 2H | |

Adhesion | 5B (EN ISO-2409:1994) | |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) | |

Flexibility (T-bend) | 0T- 2T | |

MEK resistance | 100 | |

Certification | ISO9001,SGS | |

Usuage | Exterior applications | wall cladding, facades, roofs and canopies, tunnels, |

Interior applications | wall cladding, ceilings, bathrooms, kitchens and | |

Advertisement and market applications | display platforms, signboards,fascias and shop fronts | |

Coil's standard diameter | 1100mm | |

Coil's standard weight | 2000kgs | |

Botton side aluminium sheet is coated with protective polyester material,thickness more than 6 micron | ||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

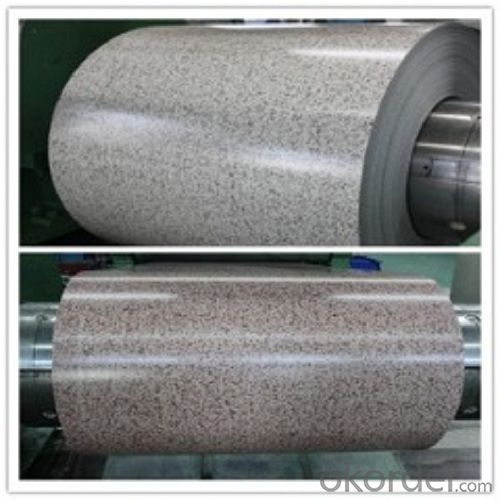

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: Just want to know for any boat builders out there. I have been told by my local paddling store that there are no aluminum kayaks. Why couldn't i build one? it cant be weight, I would build the frame from 1/2 inch square aluminum tubing and the body out of 1/32 high grade sheeting. So why does something like this not exist?

- Aluminum kayaks have been built. Few amateur builders know how to weld much less weld aluminum. Ideally you would need female molds and a press. Stretch forming can harden the aluminum and eliminate the need for a frame. If you make male molds, you could force form deck and hull parts and then join them. Read about amateur airplane builders. The big concern with an aluminum kayak is its tendency to stick to river rocks. Every whitewater run has devoured scores of aluminum canoes. Steel is possible.

- Q: How many atoms are there in a piece of aluminum foil, 7.3 inches in length and 12.0 inches in width, and 0.141 mm thick? According to this problem, aluminum foil is a flat-rolled product, rectangular in cross section, of thickness from 0.006(0.15mm) to 0.00025(0.006mm). The density of Al is 2.699 g/cm3.

- What you want to do is determine the mass of the piece of aluminum foil and then convert that to number of atoms. I'll give some pointers and you can fill in the rest: 1. Calculate the mass of the foil: a. Convert the length and width of the foil into centimeters. b. Convert the thickness of the foil into centimeters. Use your 0.141 mm figure. c. Now multiply the length times width times the height to give you the volume in centimeters. d. Now multiply this volume calculated in step c times the density of aluminum. That will give you the mass of your piece of foil. 2. Convert this mass into number of atoms. a. From the periodic table you know that there are 26.982 grams per mole of Al b. There are 6.02 x 10^23 atoms in a mole. c. So, take the mass calculated in Part 1 and divide it by 26.982 grams per mole of Al. That will give you the number of moles of Al in your piece of foil. d. Now take this number of moles and multiply it by 6.02 x 10^23 atoms in a mole, and that will give you the number of atoms in your piece of foil.

- Q: How do aluminum coils perform in applications where high strength is required?

- Aluminum coils are known for their excellent performance in applications where high strength is required. Despite being a lightweight material, aluminum possesses remarkable strength properties that make it an ideal choice for various industries. One of the key factors contributing to the high strength of aluminum coils is their alloy composition. Aluminum alloys can be tailored to enhance their strength by adding elements such as copper, magnesium, and zinc. These alloying elements form intermetallic compounds, which significantly increase the strength of the aluminum without compromising its overall weight. Additionally, aluminum coils undergo various manufacturing processes, such as hot or cold rolling, to further enhance their strength. These processes align the grain structure of the metal, making it stronger and more resistant to deformation. The resulting aluminum coils can withstand high stresses, making them suitable for applications that require durability and reliability. Moreover, aluminum coils exhibit excellent corrosion resistance, which further contributes to their performance in high-strength applications. Aluminum naturally forms a protective oxide layer on its surface, which prevents corrosion and ensures long-term durability. This corrosion resistance is crucial in environments where high-strength materials are exposed to moisture, chemicals, or harsh weather conditions. Furthermore, aluminum coils offer exceptional thermal conductivity, allowing for efficient heat dissipation in applications such as heat exchangers or radiators. This property is vital in industries where high-strength materials must also handle high temperatures, as it helps prevent overheating and subsequent material degradation. Overall, aluminum coils excel in applications where high strength is required due to their alloy composition, manufacturing processes, corrosion resistance, and thermal conductivity. Their combination of strength, lightweight design, and durability makes them a preferred choice in various industries, including automotive, aerospace, construction, and electrical.

- Q: Is it possible to utilize aluminum coils in the construction of solar panels or wind turbines?

- <p>Aluminum coils can be used in the construction of both solar panels and wind turbines, but not as the primary material for energy conversion. In solar panels, aluminum is often used for framing and mounting structures due to its lightweight and corrosion-resistant properties. For wind turbines, aluminum is utilized in the manufacturing of certain components such as nacelle shells and towers, but the main rotor blades are typically made from composite materials for their strength and aerodynamic properties. Thus, while aluminum plays a supportive role in these renewable energy technologies, it is not the core material for capturing solar or wind energy.</p>

- Q: Are aluminum coils resistant to chemicals?

- Yes, aluminum coils are generally resistant to chemicals. Aluminum has a natural oxide layer that forms on its surface, which provides a protective barrier against many chemicals. This oxide layer helps to prevent corrosion and degradation of the aluminum coils when exposed to different substances. However, it is important to note that some chemicals can still have an adverse effect on aluminum, particularly strong acids or alkalis. In such cases, additional protective coatings or treatments may be necessary to enhance the chemical resistance of the aluminum coils.

- Q: Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q: Can aluminum coils be used in the production of architectural panels?

- Aluminum coils have the capability to be utilized in the manufacturing process of architectural panels. Aluminum is a multifunctional material that is extensively employed in the construction sector because of its lightweight nature, durability, and resistance to corrosion. By rolling aluminum ingots into thin, flat sheets, aluminum coils provide a practical and effective means of producing architectural panels. Architectural panels, including aluminum composite panels (ACP) or solid aluminum panels, are commonly adopted as cladding systems for buildings. These panels serve both functional and aesthetic purposes by providing protection against the weather, insulation, and enhancing the overall appearance of the structure. Aluminum coils are implemented in the production of architectural panels due to their ease of forming and shaping into various designs, such as flat sheets, corrugated panels, or custom profiles. The coils can be cut to the desired size and then processed using various techniques, including bending, folding, punching, or welding, to create the desired shape and dimensions of the panels. Moreover, aluminum coils offer an extensive range of finishing options, such as anodizing, powder coating, or painting, which facilitates customization and improves the aesthetic appeal of architectural panels. These finishes not only provide a variety of color choices but also enhance the durability and resistance to weather of the panels. To summarize, the versatility, durability, and aesthetic options provided by aluminum coils make them a suitable choice for the production of architectural panels. The use of aluminum coils in the construction industry has gained popularity due to their cost-effectiveness and efficiency in creating high-quality panels that meet the functional and design requirements of modern architecture.

- Q: Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight properties, and corrosion resistance. Aluminum coils are commonly used in various electrical applications such as transformers, motors, generators, and coils for inductors and solenoids. They offer advantages such as high thermal conductivity and low eddy current losses, making them efficient in transferring and distributing electrical power. Additionally, aluminum coils are cost-effective compared to copper coils, making them a preferred choice for many electrical applications. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the coil design and dimensions may need to be adjusted accordingly to ensure optimal performance.

- Q: How do aluminum coils compare to other metal coils?

- Aluminum coils are generally lighter, more corrosion-resistant, and have better thermal conductivity compared to other metal coils. They are also easier to shape and mold, making them a popular choice in various industries including automotive, aerospace, and HVAC.

Send your message to us

Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords