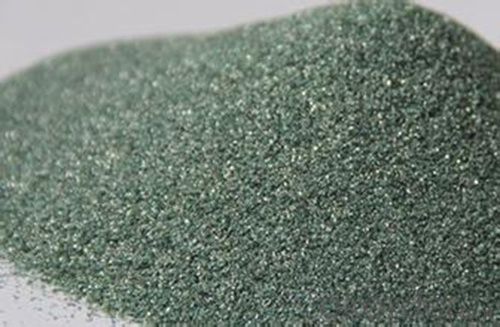

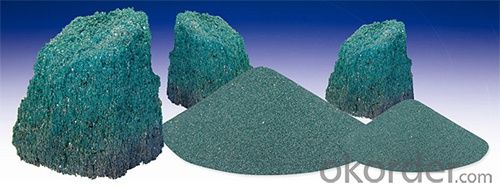

Raw Materials for Refractory:Silicon Carbide Green Abrasives & Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GREEN SILICON CARBIDE(GC)

Green silicon carbide is characterized by strong grinding efficiency and good heat-conductivity. Its hardness and strength are higher than fused alumina.

Applications:

1. Used to grind hard and brittle metal alloys, non-ferrous metals and non-metallic

materials like jewels,optical glass and ceramics.

2. Suitable for manufacturing vitrified wheels and belts, organic wheels and sheets.

3. Applied to refractory industry.

4. Powder of GC is also used as wire sawing semi-conductor raw materials.

Chemical Composition:

Type | Grit | Chemical Composition(%, by weight) | ||

SiC(≥) | F.C(≤) | Fe2O3(≤) | ||

GC | F20-F90 | 99.0 | 0.20 | 0.20 |

F100-F150 | 98.5 | 0.25 | 0.50 | |

F180-F220 | 97.5 | 0.25 | 0.70 | |

F240-F600 | 97.0 | 0.30 | 0.70 | |

F800-F1200 | 95.5 | 0.40 | 0.70 | |

P12-P100 | 99.0 | 0.20 | 0.20 | |

P120-P150 | 98.5 | 0.25 | 0.50 | |

P180-P220 | 97.5 | 0.25 | 0.70 | |

P240-P1000 | 97.5 | 0.30 | 0.70 | |

P1200 | 95.5 | 0.40 | 0.70 | |

GC-B | F20-F90 | 98.5 | 0.25 | 0.25 |

F100-F150 | 98.0 | 0.30 | 0.55 | |

F180-F220 | 97.0 | 0.30 | 0.80 | |

F240-F600 | 96.5 | 0.35 | 0.80 | |

F800-F1200 | 94.5 | 0.45 | 0.80 | |

GC-P | P12-P100 | 98.5 | 0.25 | 0.25 |

P120-P150 | 98.0 | 0.30 | 0.55 | |

P180-P220 | 97.0 | 0.30 | 0.80 | |

P240-P1000 | 96.5 | 0.35 | 0.80 | |

P1200 | 94.5 | 0.45 | 0.80 | |

Note: Special requirements can be satisfied by negotiation.

- Q: What kind of flexible fireproof material is really good?

- The best one is grade A fireproof material. A-class fire flexible material adopts clay, stone, sand, cement blocks and other inorganic powder and modifier and product density is 2327 kg/m3. Upon examination, the combustion performance of this product is in accordance with the grade A specified requirements and additional classification meets A s2, d0, t0 level requirements. According to GB 8624-2006, the combustion performance of product reach A2 - s2, d0, t0 level.

- Q: What brands are the best in the A-level refractory materials?

- This is two descriptions, glass wool refers to the texture of insulation materials, and A-lever refers to the combustion performance of fireproof materials. Generally the glass wool can achieve A-level combustion performance, unless you have add too many other combustible materials to it.

- Q: Physical and chemical indicators of various refractory.

- There are too many of them.

- Q: What are the new refractories? What are the features? How about their application and development?

- In metallurgy, in what position should it be used, in order to make the best. Answers are as following. In iron, steelmaking or converter. When questioning, pay attention to the ways. Answers: Try to use synthetic refractory materials.

- Q: Selection of refractory materials?

- Inorganic non-metallic material with a refractoriness of more than 1580 degrees. Refractoriness refers to the temperature of a sample of a refractory cone, which is resistant to high temperature without softening, and does not soften and melt down. Refractory materials are associated with high temperature technology, which originated roughly from the middle of the bronze age. In the Eastern Han Dynasty has made China kiln firing porcelain material and with fireclay refractory sagger. In the early twentieth Century, refractory materials were developed towards high purity, high density and ultra high temperature products. At the same time, unshaped refractory materials and refractory fibers without firing and energy consumption were developed. With the development of modern technology, atomic energy, space technology, new energy technology, refractory material having high temperature resistance and corrosion resistance, thermal shock resistance, erosion resistance and other comprehensive excellent performance has been applied.

- Q: How should refractory cement be used?

- How to use refractory cement? How to use refractory cement? Thank you.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q: what is the fireproofing material of engine room? who knows it ?

- 1. The new type fire?retardant?coating in fire retardant coating, the expanded vermiculite, expanded perlite heat insulation material and cenosphere adiabatic powder, etc. These inorganic component, is a major part of the thick coating type of fireproof coating, and they also are the major factor affecting the level of performance of fireproof coatings. The fireproofing thermal insulation properties of fireproof coating, is mainly determined by the fire back surface temperature of this factor, but also related to the fire endurance. If it reaches the same temperature for a longer time, it shows that it's fireproof thermal insulation is better, and the fire endurance therefore is higher. 2. The new fireproof board new fireproof board now is welcomed by the people and the important factor is its environmental protection, and with the increasing high-rise buildings, the fire protection requirements and strength requirements are also rising, it is a big challenge for the performance and standard of the fireproof board.. Now fireproof board is mainly used siliceous material or calcareous materials, and then mixed with the fiber material, lightweight aggregate, adhesives and chemical additives, it is not only be fireproofing, but also improve their thermal insulation performance, and light weight, good carrying capacity, good durability, no aging problem, more importantly, it is good in environmental protection.

- Q: what is the specs of thermal insulation refractory slab ?

- fireproof?panel is also called refractory slab, which refers to a layer of veneer. Its thickness is generally about 0.8 mm and there is a veneer made after compression of surface layer of paper, colored paper and multilayer kraft paper. Wear-resistant, heat-resistant and fire-resistant properties, scratch resistant and easy to clean, rich colors and good stability.

- Q: how to classify the fireproofing material levels A1 A2 B1?

- their classification is shown specifically in Fireproof? Specification of Building Interior Decoration?Design GB 50222-95 appendix A, flammability,inflammability materials, flame retardency, noninflammability: combustion performance of A, B3, B2, B1 materials are divided into

Send your message to us

Raw Materials for Refractory:Silicon Carbide Green Abrasives & Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords