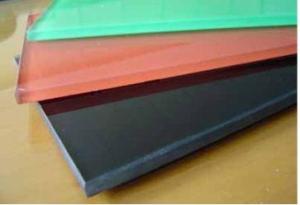

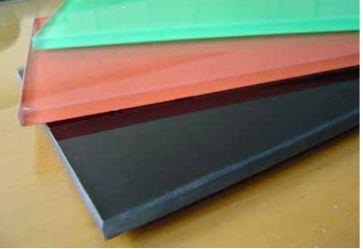

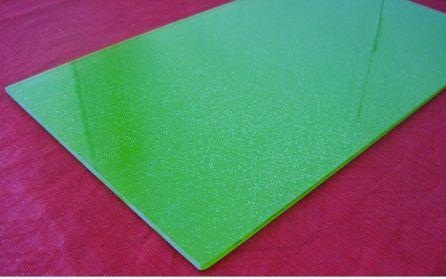

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions. Maximum processing size: 2500 mm * 8000 mm Minimum processing size: 200 mm * 300 mm The range of glass thickness: 6.38mm to 50 mm Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass. Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively. Laminated glass A. The selection of suitable float glass pane in storage Access to the next process after the quality inspection of float glass B. The measurements of glass to be cut as customized C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection D. Cleaning by deionized water

Access to the next stage after cleaning the glass E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass F. Cleaning by deionized water Access to the next stage after cleaning the glass G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling I. Inspection during the production process J. Vacuumizing treatment in autoclave

Inspection during the production process K. For subsequent processing and Packaging L. Leading Time:10 days for an average area of 1000 square meters tempered glass M. Trade terms: FOB and CIF. N. Payment Terms: By TT, 30% deposit to start producing, full amount balance paid before delivery. O. Loading and transport |

- Q: What is this wall of glass building material called?

- Glass curtain wall, coated glass or low-E

- Q: it would be awesome to have glasses with a built in computer.

- yes you can but there would have to be batteries or a cord included

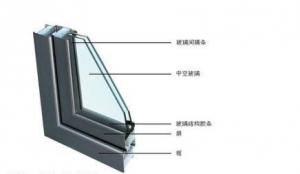

- Q: Plane picture glass screen illustration

- Of course, you can also add the details of the vertical drawing out. This is the architectural drawings of the painting, if it is a special curtain wall drawings, then you need to support the structure of the curtain wall is also expressed.

- Q: Lanzhou Huazhong hollow glass factory where

- I was in Chengdu, Sichuan State-level economic and technological development zone of glass deep processing enterprises, in our park also Huacao building materials, and its enterprises mainly engaged in the production of steel profiles and sales, but also set up a steel doors and windows factory, including products, there are insulating glass Building glass supporting sales.

- Q: What is the difference between tempered glass and ordinary glass?

- Can be affixed to the glass on the super-architectural glass insulation film, thermal explosion-proof UV Nantong super-film 1 3386 2831 Ultra-film building insulation film and decorative glass film has become the new darling of home decoration. Many families prefer this new energy-saving film, because it has excellent energy efficiency. Hot summer, super-film building insulation film and glass insulation film can block 80% of the sun's heat, adhere to the indoor relatively cool, reduce the use of air conditioning and other refrigeration and tempering facilities, saving electricity costs, reduce energy consumption. Practice has proved that the installation of building insulation film and glass insulation film family, summer, even the power outage period can also have a relatively comfortable living environment

- Q: I want to build a small soundproof glass room in my living room, since i have another family member moving in and it will be hard to talk over the phone at night and listen to music, since I already share my room. I picture it as big as a phone booth but just longer some how so I can lay in it and just talk on the phone or use my laptop. I have no idea what company I should search for to build a glass soundproof room that small. or maybe it can be about 10 feet by 5 feet. No matter if its sliding door or not. Any info would help me. Thanks Even personal stories on other kinds of soundproofing that works thats affordable.

- Build A Soundproof Room

- Q: Used to make insulating glass for doors and windows or insulating glass or architectural glass!

- There is now a conductive glass, but not our common ordinary glass, but a new type of inorganic nonmetallic materials, such as: ITO conductive glass, is based on soda-lime or silicon-boron substrate glass, The method of sputtering is coated with a layer of indium tin oxide (commonly known as ITO) film processing made. LCD display dedicated.

- Q: The basic characteristics of self cleaning glass

- Hydrophobe: refers to a substance (a molecule) that has a strong repellent effect on water, and water forms a large contact angle on the surface of a hydrophobic object. We have the same effect.

- Q: Through the glass after the sun came in with the glass can not be compared to those who will be the skin of the sun more black ah? Seek experts

- So that the skin is black, is the sun in the ultraviolet. Ultraviolet rays are wavelengths shorter than visible light. The wavelength is between 390 and 400 nm. It can pass through the air, but it is not easy to pass through the glass, has the ability to sterilize, and has some damage to the eyes and skin.

- Q: Architectural glass companies need to apply for which qualification documents

- The material of the glass consists of three parts: basic raw materials, flux and colorant, as well as decolorizing agent, clarifying agent and emulsifier.

Send your message to us

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords