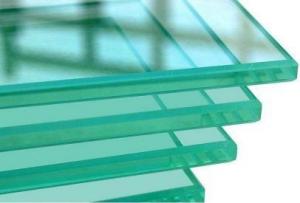

Green Toughened glass6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestation

Provide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: How is a mortar set glass block wall built?

- go to howits made and type in how to lay a glass block wall

- Q: What kind of new glass is there now?

- There are: folder wire mesh anti-theft glass, there is a folder silk glass, discoloration glass, eat glass, heat-absorbing glass

- Q: I am about to build an all-glass aquarium, the glass edge-joined with silicon. I have seen it done a number of times and am confident I am able to do it. The finished tank size will be 150cm long, 60cm tall and 50cm deep. I intend to brace the front and back as well as the two sides and also put two cross braces running front to back at the top of the tank at 50cm and 100cm intervals. Does anybody know how I should calculate the glass thickness or, alternatively, does anyone out there have a tank of a similar size they could tell me what the dimensions of theirs is.Thanks

- 92x37x38cm what s thickness I should used

- Q: Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q: Instead of spending thousands of dollars on new windows in certain areas i am going to build my own for sheets of glass and metal/wooden framing. Is there anyone out there who knows of a decent diy window project site or book. I am going to try and make the windows as energy efficient as possible and i would like to know any ways this might be achieved.any help would be greatly appreciated.

- I've never broke down the prices, but I bet you end up spending more. If not initially, then in the long run. Insulated glass, which you will need to order, will be somewhat expensive. And probably won't do as well as what a moderately priced replacement window. I spent about 3 grand on 15 Pella windows (11 double hung, 4 small sliders for the basement) You will end up using wood jambs, sashes. Plus hardware. It will take a long time to build the windows, time you could spend making money other ways to pay for the windows. It will be harder to get the windows air tight. So in the end, a good replacement window will save you more in time and energy savings, then a home made version.

- Q: I have a chinese water dragon. He is still a baby but I'm looking to build him a bigger cage as he will grow to possibly three feet in length. I've searched the net for ideas on his cage and I'd like to use glass or plexi-glass on the sides and front of the cage. Even though I've looked at all the youtube videos I can find and any free plans I can find, I can't find a good way to build doors with glass, or plexi-glass, in them. I might just go with a sliding door but I'd prefer a door or two similar to a cabinet door. The opening is most likely going to be about 4 feet high. I also can't figure out how to attach the side, glass/plexi-glass, panels.I have basic tools but I don't consider myself a great carpenter. In other words, it needs to be simple.Any suggestions/help would be wonderful.

- Have you considered scrubbing it with disinfectant, then spraying a sealant over the top of the current paintjob and then once that has fully cured, then re-repainting it to the colour you want (in a paint that won't harm your pet) ? it's the best idea i have.

- Q: Has anyone built a greenhouse using discarded sliding glass doors?

- Haven't yet, but plan to. A friend did it and it looks and works great. He even used two sets on the roof - replaced the glass with plexiglass - so can open when it gets too hot. He used aluminum framing - like for a carport and spaced the frame so the doors would fit (used a double carport frame that he extended 6 feet) and used clear plastic siding to fill in the spaces above doors and on the ends. It looks really nice.

- Q: Would you like to make windows white glass is good or green is good? That expensive Looks upscale? Thank you!

- Ordinary flat glass Ordinary flat glass with light transmission, insulation, sound insulation, wear resistance, resistance to climate change performance, and some insulation, heat absorption, radiation and other characteristics, which are widely used in mosaic buildings doors and windows, Interior decoration and so on.

- Q: What is the difference between screen printing glass and glazed glass? The What is the difference between product performance, production methods, what is the difference

- Screen printing is a printing method, and the use of a lot of printing, printed on the glass up to the color glaze and frosted plaster. It should be said: color glaze glass is a kind of silk screen glass.

- Q: Curtains can not pull the first ten centimeters, glass cover, what way to cover

- Posted architectural glass film

Send your message to us

Green Toughened glass6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords