7mm Aluminum Sheet with Different Specifications - Aluminum Corner Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminium was selected as the material to use for the 100 ounces (2.8 kg) capstone of the Washington Monument in 1884, a time when one ounce (30 grams) cost the daily wage of a common worker on the project (in 1884 about $1 for 10 hours of labor; today, a construction worker in the US working on such a project might earn $25–$35 per hour and therefore around $300 in an equivalent single 10-hour day).[69] The capstone, which was set in place on 6 December 1884 in an elaborate dedication ceremony, was the largest single piece of aluminium cast at the time.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

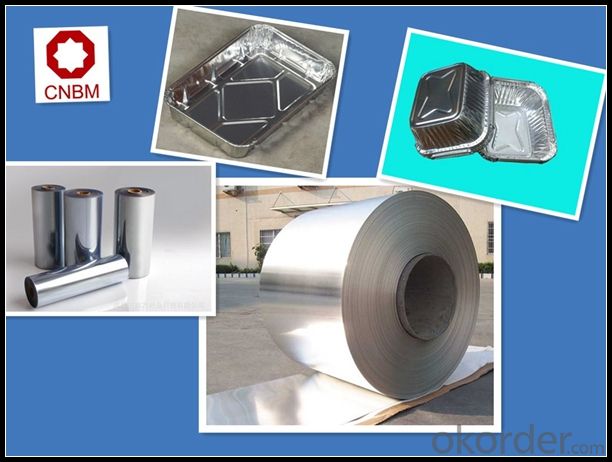

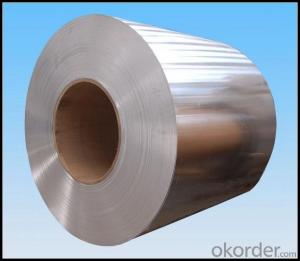

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks about the impact of temperature on the performance of aluminum strips used in construction.

- <p>Temperature significantly affects the performance of aluminum strips in construction. At low temperatures, aluminum becomes more brittle, reducing its ductility and increasing the risk of cracking or breaking under stress. Conversely, high temperatures can cause aluminum to lose strength and become more susceptible to deformation. It's crucial to maintain optimal working temperatures to ensure the structural integrity and longevity of aluminum components. Additionally, temperature fluctuations can lead to thermal expansion and contraction, affecting the fit and alignment of aluminum strips, potentially causing gaps or misalignments in constructions.</p>

- Q: What are the elements and compounds that make up aluminum strips?

- <p>Aluminum strips are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and malleable metal. Aluminum is a pure element and not a compound, so its composition is straightforward. It is found in Group 13 of the periodic table and has an atomic number of 13. In its pure form, aluminum is soft and lacks sufficient strength for many applications, so it is often alloyed with other elements such as copper, magnesium, manganese, silicon, and zinc to improve its strength and durability. These alloying elements can make up a small percentage of the total composition, but they significantly enhance the properties of the aluminum strips for various industrial uses.</p>

- Q: What benefits are associated with the use of aluminum strips on the exterior walls of buildings?

- <p>Aluminum strips for exterior walls offer several advantages, including durability, resistance to corrosion and weathering, and low maintenance requirements. They are lightweight, which can reduce the load on the building structure. Aluminum strips also provide excellent heat insulation properties, contributing to energy efficiency. Additionally, they can be easily shaped and bent, allowing for versatile and modern architectural designs. The recyclability of aluminum makes it an environmentally friendly choice, and its non-combustible nature enhances safety in construction.</p>

- Q: Is it possible to utilize aluminum strips in construction for decking or fencing purposes?

- <p>Yes, you can use aluminum strips for decking or fencing projects. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It is lightweight, easy to install, and can withstand various weather conditions. Aluminum strips can be used to create modern and sleek designs, and they are also recyclable, making them an environmentally friendly option. However, it's important to ensure that the aluminum strips are of suitable thickness and quality to bear the weight and stress expected in your specific project.</p>

- Q: This question asks for an explanation of the various kinds of aluminum strips that exist, which could include their properties, uses, and any other distinguishing features.

- <p>Aluminum strips come in various types, differentiated by their alloy composition, thickness, width, and temper. Common types include 1000 series strips, which are 99% pure aluminum, known for their high thermal and electrical conductivity. 3000 series strips, like 3003 alloy, offer good formability and are used in cooking utensils and chemical equipment. 5000 series strips, such as 5052, are known for their strength and are used in marine applications and aircraft structures. 6000 series strips, like 6061, are heat-treatable and used in construction and automotive parts. Each type has specific properties that make them suitable for different applications, from lightweight structures to high-strength components.</p>

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: How can the aluminium band be welded to the steel shell?

- If it is more than 0.5 mm by resistance heating welding, welding materials need to use the 303B welding wire Odin wei.Welding tools: carbon block welding, welding with two electrodes.

- Q: This question asks for methods to prevent rusting on aluminum strips during both installation and use.

- <p>To prevent rusting on aluminum strips, ensure that the aluminum is of high quality and free from impurities. Keep the strips clean and dry during installation and use. Avoid contact with corrosive substances. Apply a protective coating or sealant if necessary. Regularly inspect and clean the aluminum strips to remove any dirt or moisture that could lead to corrosion. In case of scratches or damage, promptly repair and seal the affected areas to prevent moisture penetration.</p>

- Q: Is it possible to use aluminum strips as a covering for window or door frames?

- <p>Yes, you can use aluminum strips to cover window or door frames. Aluminum is a durable and lightweight material that can provide a sleek finish to your frames. It is resistant to corrosion and weathering, making it suitable for both indoor and outdoor applications. Aluminum strips can be easily cut and shaped to fit the contours of your frames, and they can be painted or anodized to match your desired aesthetic. However, ensure proper installation to maintain structural integrity and weatherproofing.</p>

Send your message to us

7mm Aluminum Sheet with Different Specifications - Aluminum Corner Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords