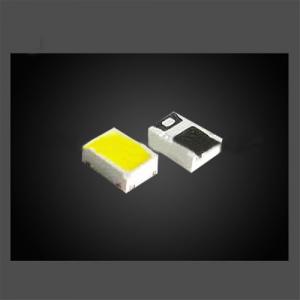

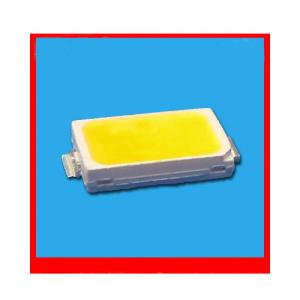

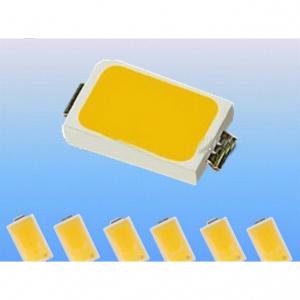

SMD 5630 0.5W 50lm to 60Lm LED Chips Epistar

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SMD 5630 0.5W 50-60LM led chips epistar

Features:

lEmitted color: super yellow

lLens color: Water clear

lLuminous Intensity: Min 40LM Typ. 45Lm

lViewing angle:120 deg

lColor temperature: 2700-3500 K

lForward voltage:2.8 3.4 3.8 V

lReverse voltage:5V

lCE and Rohs compliant

lSuitable for vapor-phase reflow, Infrared reflow and wave solder processes.

lCompatible with automatic placement equipment.

l Available on tape and reel (8mm Tape).

lThe R5630 series is available in soft green, blue, and white. Due to the package design,

Descriptions: The LED has wide viewing angle and optimized. Light coupling by inter reflector. This feature makes the TOP View LEDs ideal for portable equipment or any other application where is at a premium.

Package:1000pcs/reel

Application:

1. Lightings

2. Miner's lamp

3. Optical indicator

4. Signal & symbol luminaire.

5. Substitution of Micro incandescent lamps

6. Indoor & outdoor displays

7. Backlightings (LCD, cellular phone, switches, keys, displays, advertising)

Our advantages:

1.16 years experience in manufacturing, Encapsulation Center for LED in Xiamen

2.LED components supplier for LG,TPV,Lite-on, Mitsubishi

3.Well-trained and experienced staffs to help you slove your problem

4. A experienced R&D team to help design new products

5. Strict QC system for high quality

6. Guaranteed delivery time

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q: Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- First of all, I want to say, in the same light emitting chip case, two is not what were, just a different process is a DIP plugin, a SMD patch process, the 3 floor of the right, just some high grade patch.

- Q: Patch LED light does not flash, why?

- Are you saying that lamp is flashing? You can check the power output, according to your standard parameters and SMD beads, lamp panel series parallel mode, calculate the power output to output power of the test, you may be wrong, power, overload, but also the effective part of you may be the circuit for power transmission is not stable or low

- Q: How to detect LED SMD beads

- Resistance voltage ordinary pointer table 1.5V in general, and some only in the high resistance file (*10K file) with 9V or 15V battery, so the pointer table to measure LeD beads to hit the highest resistance profile measurement, otherwise useless, of course, at this time the brightness is very small, can not see, can only to judge the positive and negative resistance values see.

- Q: What does patch LED light mean?

- The screen is divided into standard lamp and patch type, the light emitting diode lamp is inserted into the circuit board, and the patch is a patch welded on the circuit board. Two light sources are not the same. If only light, not so clear.

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

- Q: What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

- Q: The quality of the LED patch module

- Quality of circuit board. In the same quality of LED, the quality of PCB will have an important impact on the life of LED. The circuit board is divided into aluminum plate, glass fiber board, semi glass fiber board and paperboard. The quality of aluminum is the best, the best cooling effect, but the cost is too high, the domestic manufacturers generally only in high-power LED products use, LED module manufacturers generally use cardboard, semi glass fiber and glass fiber board. Module, piranha, straw hat module monochrome is generally used in cardboard or semi glass, commonly used glass fiber or semi SMD glass fiber board. Colorful and full color module series generally at least half of glass fiber, so as to match.

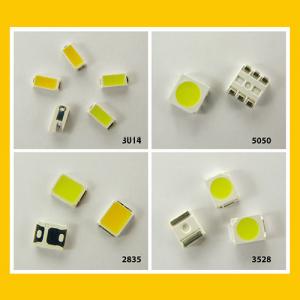

- Q: What does "1210" mean in patch LED?

- 1210 represents the size of the LED package specification (size, specification), and represents the length and width of the resistanceSpeed adoption!!!

Send your message to us

SMD 5630 0.5W 50lm to 60Lm LED Chips Epistar

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords