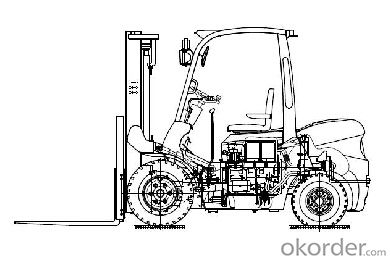

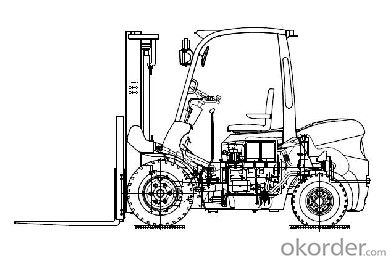

5 Tons Diesel Powered Forklift product CPCD50F

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations. In 2013 alone the top 20 manufacturers worldwide posted sales of $30.4 billion with 944,405 machines sold.;and the U.S. forklift market was nearly $33 billion.

General operations

Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

Forklift control and capabilities

Forklift hydraulics are controlled either with levers directly manipulating the hydraulic valves, or by electrically controlled actuators, using smaller "finger" levers for control. The latter allows forklift designers more freedom in ergonomical design.

Hydraulic elevator for tractors

Forklift trucks are available in many variations and load capacities. In a typical warehouse setting most forklifts have load capacities between one and five tons. Larger machines, up to 50 tons lift capacity, are used for lifting heavier loads, including loaded shipping containers.

In addition to a control to raise and lower the forks (also known as blades or tines), the operator can tilt the mast to compensate for a load's tendency to angle the blades toward the ground and risk slipping off the forks. Tilt also provides a limited ability to operate on non-level ground. Skilled forklift operators annually compete in obstacle and timed challenges at regional forklift rodeos.

Design types

A truck mounted forklift.

The following is a list, in no particular order, of the more common lift truck types:

Hand pallet truck - no on-board power system of any kind; the operator's muscle power is used to jack-up and move loads.

Walkie low lift truck- powered pallet truck, usually electrically powered

Rider low lift truck - usually electrically powered

Towing tractor - may be internal combustion engine or electrically powered

Walkie stacker - usually electrically powered

Rider stacker - usually electrically powered, e.g., A Ergo

Reach truck - variant on a Rider Stacker forklift, designed for small aisles, usually Electrically Powered, named because the forks can extend to reach the load. There are two variants, moving carriage, which are common in North America, and moving mast which are common in the rest of the world, and generally regarded as safer.

Forklift Specification:

Model | CPCD50F | |

Load capacity kg | 5000 | |

Load center mm | 500 | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 375 | |

Max.Driving speeds(with without load)km/h | 20/24 | |

Max.Towing speeds(with/without load)kN | 31/18 | |

Gradeability(with/without load)% | 15/20 | |

H1 Lifting height mm | 3000 | |

Free lift mm | 150 | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 3000 | |

Min. right angle aisle width mm | 2750 | |

Min. under-clearance mm | 170 | |

Dimensions | A Overall length (inincluding fork) mm | 4350 |

B Overall width mm | 1400 | |

H Overall height(mast lowered) mm | 2330 | |

H2 Overall height(mast extend) mm | 4265 | |

H3 Overall height to overhead guard mm | 2330 | |

A1 Fork overhang mm | 565 | |

A2 Wheel base mm | 2150 | |

Tread | B1 Front tread mm | 300-15 |

B2 Rear tread mm | 7.00-12 | |

Tyre | Front tyre | 1180 |

Rear tyre | 1190 | |

Total weight kg | 6800 | |

B3 Fork width mm | 150 | |

H4 Fork thickness mm | 55 | |

Backrest height mm | 1275 | |

A3 Fork length mm | 1070(1220) | |

Engine | Engine model | LR4A3-G |

Rate power KW | 59 | |

Rotate Speed At Rate Power rpm | 2400 | |

Max.torque Nm | 275 | |

Rotate speed at max torque rpm | 1680 | |

Type of power shift | Hydraulic | |

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How do you use the gta5 forklift, the one that carries the container on the dock

- Then press CTRL to push the arm to the container and press E.I hope my answer is useful to you.

- Q: How to drive a forklift

- Forklift truck than a car drives well No I drive a car but often see loading should see good open in to my factory and other customers in suzhou, Shanghai, zhejiang and so on No, I only in jiangsu, zhejiang, anhui delivery other far away don't run

- Q: How long is the forklift?

- At home, it is a new energy hydraulic machinery factory in taixing city.I hope my answer will help you.

- Q: How many ways to push the forklift truck?

- Heavy forklift trucks are powered by diesel engines, carrying capacity of 10.0-52.0 tons, which is commonly used in outdoor work in industries such as heavy wharf and steel.

- Q: The forklift oil cylinder is leaking, and the newly replaced oil seal is no good

- Inside leak, you check if the piston rod is injured. There is no scratch inside the cylinder. Let's see if the piston has a stomata. Maybe the piston and the piston rod link to where the sealing is not good. Check it out carefully.

- Q: Is it dangerous to drive a forklift?

- Some! As far as I know forklift is dangerous, maybe you haven't contact with the line, or contact time is not long, I experience that once I driving forklift fast and then a sharp turn, forklift nearly doubled, at that time if it weren't for reflect the fast, I'm afraid his life did not have. Another time I looked at a colleague who was pushing a woman to death when he turned from the door. So you have to be careful about driving a forklift. Work 3-4 hours and you will feel mentally paralyzed, especially in the middle of the summer, so drive a forklift must be focused

- Q: What are the traffic rules for forklifts

- Safety regulations for forklift trucks The head of the facility shall strictly require the personnel who have received the training and obtaining the certificate to drive the forklift truck. 2. The forklift driver to use checklist to check before, during, and after using forklifts, including all alarm and safety device (see chart), and immediately report to the supervision of a forklift any failure situation; If there is a problem with the brake, you may not use a forklift truck. The trailer or truck for loading and unloading should be put on the brakes and stuck in a block to prevent the car from sliding. Only carry items within the capacity of the forklift. The lifting of the weight is low, and the fork is not more than 8 inches off the ground and leans back. Make sure the load is stable and not tip over when turning.

- Q: What's the difference between a forklift?

- Is a kind of special equipment operation operation certificate issued by the municipal pledges inspect bureau, a green book, the project may not write forklift 2 words, write the code N2 (on behalf of the forklift truck), the enzyme, called operation certificate, necessary to mount guard. Another kind is people club bureau (former labor bureau) issued by the vocational qualifications, junior, senior, this card is used to assess technical level of workers, country or large enterprise to review salary.

- Q: How can the forklift truck change the antifreeze fluid and find no drainage

- Open the drain and release the old antifreeze and then install the water pipe

- Q: What procedures are required for a forklift licence

- You need to buy the invoice and the certificate from the new car, and every car has to fail, especially if the lights are OK. Then look for the quality technical supervision bureau, fill in a form, they send someone to come and check once!

Send your message to us

5 Tons Diesel Powered Forklift product CPCD50F

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords