4 Tons Diesel Powered Forklift product CPCD40FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Design types

A truck mounted forklift.

The following is a list, in no particular order, of the more common lift truck types:

Hand pallet truck - no on-board power system of any kind; the operator's muscle power is used to jack-up and move loads.

Walkie low lift truck- powered pallet truck, usually electrically powered

Rider low lift truck - usually electrically powered

Towing tractor - may be internal combustion engine or electrically powered

Walkie stacker - usually electrically powered

Rider stacker - usually electrically powered, e.g., A Ergo

Reach truck - variant on a Rider Stacker forklift, designed for small aisles, usually Electrically Powered, named because the forks can extend to reach the load. There are two variants, moving carriage, which are common in North America, and moving mast which are common in the rest of the world, and generally regarded as safer

Electric Counterbalanced truck- comes in Stand on End Control, Stand on Center Control, and Sit Down Center Control, which is the most numerous

Internal Combustion Engine Powered Counterbalanced Forklift- comes in Stand on End Control, Stand on Center Control, and Sit Down Center Control, which is the most numerous. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems.

Electric forklifts - powered by lead-acid batteries, several types of forklifts are electric: cushion tire forklifts, scissor lifts, order pickers, stackers, reach trucks and pallet jacks. Electric forklifts are primarily used indoors on flat, even surfaces. Electric forklift batteries last 6 consecutive hours or throughout an 8-hour shift with 2-3 breaks. Batteries prevent the emission of harmful fumes and are recommended for facilities in food-processing and healthcare sectors.

Fuel cell forklifts produce no local emissions, can work for a full 8-hour shift on a single tank of hydrogen, can be refueled in 3 minutes and have a lifetime of 8–10 years. Fuel-cell-powered forklifts are often used in refrigerated warehouses as their performance is not degraded by lower temperatures.

Sideloader - comes in Stand on End Control, and Sit Down End Control, which is the most numerous. It may be electrically powered, or have an internal combustion engine. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems. Some sideloaders have hybrid drivetrains.

Telescopic handler - comes in Stand on Center Control, and Sit Down Center Control, which is the most numerous. Usually has an Internal Combustion Engine. Engines are almost always diesel, but sometimes operate on kerosene, and sometimes use propane injection as a power boost. Some old units are two stoke compression ignition, most are four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries like Iran or Russia will typically have no emission control systems. Some Telescopic handlers have Hybrid drivetrains.

Walkie Order Picking truck - usually Electrically Powered

Rider Order Picking truck - commonly called an "Order Picker"; like a small Reach Truck, except the operator rides in a cage welded to the fork carriage, while wearing a specially designed safety harness to prevent falls. A special toothed grab holds the pallet to the forks. The operator hand transfers the load onto the pallet one article at a time. This is an efficient way of picking less than pallet load shipments, and is popular for use in large distribution centers.

Forklift Specification:

Model | CPCD40FR | |

Load capacity kg | 4000kg | |

Load center mm | 500mm | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 300mm/s | |

Max.Driving speeds(with without load) km/h | 18/20km/h | |

Max.Towing speeds | 16.5/11.5kN | |

(with/without load)kN |

| |

Gradeability(with/without load)% | 15/20% | |

H1 Lifting height mm | 3000mm | |

Free lift mm | 80mm | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 2720mm | |

Min. right angle aisle width mm | 2320mm | |

Min. under-clearance mm | 135mm | |

Dimensions | A Overall length(inincluding fork) mm | 4100mm |

B Overall width mm | 1230mm | |

H Overall height(mast lowered) mm | 2100mm | |

H2 Overall height (mast extend) mm | 4270mm | |

H3 Overall height to overhead guard mm | 2110mm | |

A1 Fork overhang mm | 470mm | |

A2 Wheel base mm | 1900mm | |

Tread | B1 Front tread mm | 1060mm |

B2 Rear tread mm | 970mm | |

Tyre | Front tyre | 250-15 |

Rear tyre | 6.50-10 | |

Total weight kg | 4900kg | |

B3 Fork width mm | 150mm | |

H4 Fork thickness mm | 50mm | |

Backrest height mm | 1225 | |

A3 Fork length mm | 1220mm | |

Engine | Engine model | 498 |

Rate power KW | 45KW | |

Rotate Speed At Rate Power rpm | 2500 | |

Max.torque Nm | ≥93 | |

Rotate speed at max torque rpm | 1800-1900rpm | |

Type of power shift | Hydraulic | |

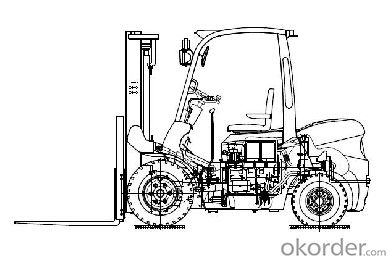

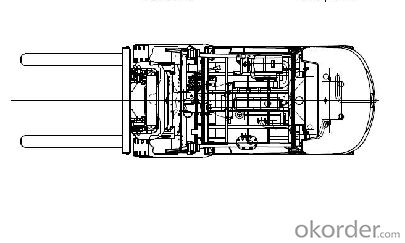

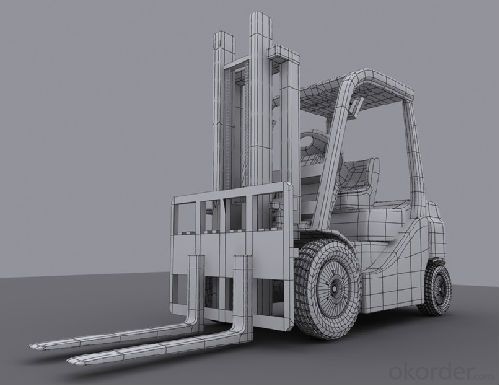

Forklift images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How to start a forklift? Say detailed point

- Do not drive when the fork is raised: when the fork rises, do not drive the forklift truck, in case the goods are depraved. Do not drive on the side of the road: make sure the forklift has sufficient safety distance from the side of the road or platform to prevent the forklift from falling. Forklift maintenance: the forklift truck is not allowed to be modified, and the daily inspection and repair of the forklift is not allowed. When the forklift has any damage or failure, the forklift truck is stopped to be repaired; The forklift truck cannot operate a forklift truck until it is overhauled. When checking the electrical system, turn off the key switch and pull out the battery plug. When adding fuel, the driver should not be in the car, and the engine will be out of the fire. When checking the battery level of the battery or tank, don't fire the ignition. Avoid sudden start, quick start, sharp turn and sudden shift of direction, and stop the sudden acceleration. You should always do a forklift based on your surroundings. The control handle is not allowed to be controlled all of a sudden: the hydraulic control handle must be operated slowly, either in full load or in empty load. When a cargo fork is at a high point, a sudden manipulation of the handle can cause the risk of deterioration of the goods or the tipping of the forklift. Don't rush to the shelves. When the door is tilted forward, the shelf is forbidden to rise: when lifting a cargo or starting a forklift, the door frame should be put in place to stabilize the goods. Under fork condition, the door should not be tilted forward. When lifting or lifting the goods, they should stop first. When the forklift is tilted, do not unload the cargo.

- Q: What is the safe speed of the forklift truck

- Forklift truck speed can be set, internal combustion forklift usually have speed limiter, domestic forklift factory basic restrictions in 18-20 km/h, battery forklift truck speed can be set according to the request of the buyer the speed of the Settings for each mode.

- Q: What are the advantages of various forklifts

- Liquefied gas forklift truck: Advantages: LPG forklift fuel price cheap, operation duration is longer, more stable operation, low noise, after adding catalyst, can make the carbon monoxide and hydrocarbon emissions down to a minimum, therefore, liquefied petroleum gas forklift truck almost no black smoke emission, no air pollution, Battery forklift Advantages: battery

- Q: The operation specification of forklift truck

- Hello, forklift safety procedures are as follows: Purpose: to regulate the safety operation of forklift vehicles and safe driving; Scope of application: forklift driver; Safety driving rules for forklifts:

- Q: What are the types of forklifts?

- Forklift can be divided into three categories: internal combustion forklift, electric forklift and storage forklift. (1) internal combustion forklift truck is divided into general internal combustion forklift truck, heavy lift truck, container forklift truck and side forklift truck. (1) general internal combustion forklift Generally use diesel, gasoline, liquefied petroleum gas or natural gas engine as power, load capacity of 1.2 ~ 8.0 tons, homework channel width is generally 3.5 ~ 3.5 meters, emissions and noise into consideration, usually used in outdoor, workshops or other places with special requirements for emissions and noise did not. Due to the convenience of fuel replenishment, long time continuous work can be achieved, and can be suitable for work in bad environment (such as rain). (2) heavy forklift Use diesel engine as power, carrying capacity of 10.0 ~ 52.0 tons, is commonly used in heavy goods wharf working outdoors, iron and steel industry, etc. (3) container forklift Use diesel engine as power, carrying capacity of 8.0 ~ 45.0 tons, generally divided into empty container stacking machine, positive &heavy container truck and container cranes. Apply to container handling such as container yard or port terminal.

- Q: Is the forklift card issued by the labor bureau or the bureau of quality supervision? Which good?

- There is no such thing as a license to drive, and a lot of years of technical proficiency can be used to get a lot of credit.

- Q: Can a power supply of 48-volt battery pack a 12 volt fan

- 48 v battery is, but on general battery forklift truck has a DC voltage converter (also called DC - DC), find the thing, from the output voltage, find the 12 v output, wiring can be installed.

- Q: What's the difference between a forklift?

- Is a kind of special equipment operation operation certificate issued by the municipal pledges inspect bureau, a green book, the project may not write forklift 2 words, write the code N2 (on behalf of the forklift truck), the enzyme, called operation certificate, necessary to mount guard. Another kind is people club bureau (former labor bureau) issued by the vocational qualifications, junior, senior, this card is used to assess technical level of workers, country or large enterprise to review salary.

- Q: What is a forklift for?

- Forklift plays a very important role in the logistics system of the enterprise, it is a very important component in logistics, it is the main force in the material handling equipment. Widely used in the national economy, such as station, port, airport, factory, warehouse, etc., it is an efficient equipment for mechanized loading and unloading, stacking and short distance transportation. Self-propelled forklifts appeared in 1917. During world war ii, forklifts were developed. China started making forklifts in the early 1950s. Especially with the rapid development of China's economy, the majority of enterprise material handling has been out of the original manual handling, instead of forklift truck is given priority to the mechanization of handling. As a result, demand in China's forklift market has grown at double-digit rates every year for the past few years.

- Q: What is the procedure of the forklift?

- The registration form of the special equipment (two copies of the original); The inspection report (original and copy) of the inspection (or periodical) in the validity period; Certificate of special equipment (original and photocopy); Product quality certificate (original and photocopy). Note: all copies need to be covered with the official seal.

Send your message to us

4 Tons Diesel Powered Forklift product CPCD40FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords