3.5 Tons Diesel Powered Forklift CPCD35FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Dimensioning devices-fork truck mounted dimensioning systems provide dimensions for the cargo to facilitate truck trailer space utilization and to support warehouse automation systems. The systems normally communicate the dimensions via 802.11 radios. NTEP certified dimensioning devices are available to support commercial activities that bill based on volume.

Sideshifter - is a hydraulic attachment that allows the operator to move the tines (forks) and backrest laterally. This allows easier placement of a load without having to reposition the truck.

Rotator - To aid the handling of skids that may have become excessively tilted and other specialty material handling needs some forklifts are fitted with an attachment that allows the tines to be rotated. This type of attachment may also be used for dumping containers for quick unloading.

Fork positioner - is a hydraulic attachment that moves the tines (forks) together or apart. This removes the need for the operator to manually adjust the tines for different sized loads.

Roll and barrel clamp attachment - A mechanical or hydraulic attachment used to squeeze the item to be moved. It is used for handling barrels, kegs, or paper rolls. This type of attachment may also have a rotate function. The rotate function would help an operator to insert a vertically stored paper into the horizontal intake of a printing press for example.

Pole attachments - In some locations, such as carpet warehouses, a long metal pole is used instead of forks to lift carpet rolls. Similar devices, though much larger, are used to pick up metal coils.

Carton and multipurpose clamp attachments - are hydraulic attachments that allow the operator to open and close around a load, squeezing it to pick it up. Products like cartons, boxes and bales can be moved with this type attachment. With these attachments in use, the forklift truck is sometimes referred to as a clamp truck.

Slip sheet attachment (push - pull) - is a hydraulic attachment that reaches forward, clamps onto a slip sheet and draws the slip sheet onto wide and thin metal forks for transport. The attachment will push the slip sheet and load off the forks for placement.

Drum handler attachment - is a mechanical attachment that slides onto the tines (forks). It usually has a spring-loaded jaw that grips the top lip edge of a drum for transport. Another type grabs around the drum in a manner similar to the roll or barrel attachments.

Man basket - a lift platform that slides onto the tines (forks) and is meant for hoisting workers. The man basket has railings to keep the person from falling and brackets for attaching a safety harness. Also, a strap or chain is used to attach the man basket to the carriage of the forklift.

Telescopic forks - are hydraulic attachments that allow the operator to operate in warehouse design for "double-deep stacking", which means that two pallet shelves are placed behind each other without any aisle between them.

Scales -Fork truck mounted scales enable operators to efficiently weigh the pallets they handle without interrupting their workflow by travelling to a platform scale. Scales are available that provide legal-for-trade weights for operations that involve billing by weight. They are easily retrofitted to the truck by hanging on the carriage in the same manner as forks hang on the truck.

Single-double forks - are forks that in the closed position allow movement of a single pallet or platform but when separated, turn into a set of double forks that allow carryin two pallets side by side. The fork control may have to replace the side-shifter on some lift trucks.

Any attachment on a forklift will reduce its nominal load rating, which is computed with a stock fork carriage and forks. The actual load rating may be significantly lower.

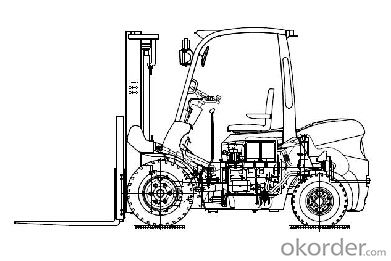

Forklift Specification:

Model | CPCD35FR | |

Load capacity kg | 3500kg | |

Load center mm | 500mm | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 375mm/s | |

Max.Driving speeds(with without load) km/h | 17/19km/h | |

Max.Towing speeds | 16/11kN | |

(with/without load)kN |

| |

Gradeability(with/without load)% | 15/20% | |

H1 Lifting height mm | 3000mm | |

Free lift mm | 80mm | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 2500mm | |

Min. right angle aisle width mm | 2110mm | |

Min. under-clearance mm | 135mm | |

Dimensions | A Overall length(inincluding fork) mm | 3800mm |

B Overall width mm | 1230mm | |

H Overall height(mast lowered) mm | 2100mm | |

H2 Overall height (mast extend) mm | 4270mm | |

H3 Overall height to overhead guard mm | 2110mm | |

A1 Fork overhang mm | 465mm | |

A2 Wheel base mm | 1700mm | |

Tread | B1 Front tread mm | 1000mm |

B2 Rear tread mm | 970mm | |

Tyre | Front tyre | 28×9-15 |

Rear tyre | 6.50-10 | |

Total weight kg | 4580kg | |

B3 Fork width mm | 125mm | |

H4 Fork thickness mm | 50mm | |

Backrest height mm | 1225 | |

A3 Fork length mm | 1220mm | |

Engine | Engine model | 490 |

Rate power KW | 39KW | |

Rotate Speed At Rate Power rpm | 2650rpm | |

Max.torque Nm | 157Nm | |

Rotate speed at max torque rpm | 1980rpm | |

Type of power shift | Hydraulic | |

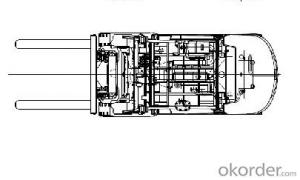

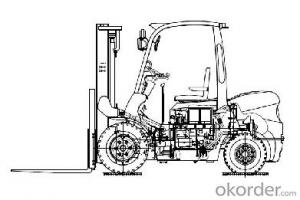

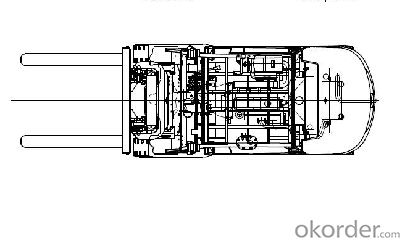

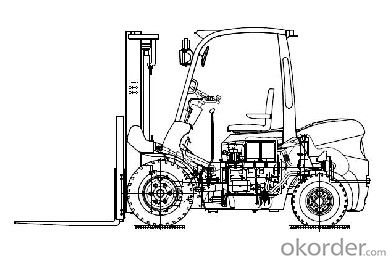

Forklift Images :

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: The forklift test has those projects

- Forklift test subject 3: forklift When driving, the bottom of the cargo fork should be kept at 300 ~ 400mm, and the door frame should be leaning back.

- Q: How about the forklift truck training, the forklift wages

- The level of skills needed to be re-established for on-the-job staff, such as position transfer. About post to create positions, forklift worker trainee 1 to 3 months after the inspection qualified rear can formal mount guard after probation period, the trainee and obtainment of the wage level of different forklift worker hired for 1 to 3 months after the probation period, probation, organization work skill examination and confirmation, after assessment is eligible to positive after giving skills rating, according to the different level skills allowance, obtainment of outstanding achievement appraisal of employees can be paid or given directly across their post grades, but the largest for level 3. For those who have had the higher skills and experience in the position, they may be qualified as junior, intermediate or senior.

- Q: The forklift oil cylinder is leaking, and the newly replaced oil seal is no good

- Check the whole hydraulic system, find the leak point, and focus on the oil cylinder. It may be a seal problem.

- Q: There are several forklift drivers in China

- The name of a forklift truck is a professional proof of a forklift driver. Forklift plays a very important role in the logistics system of the enterprise, which is the main force in the material handling equipment.

- Q: Is a forklift a special type of work

- Hello, forklift driver belongs to special equipment operator, not belong to special type of work.

- Q: What are the types of forklifts?

- Depending on the location of the cargo fork, Fork lift truck. It USES more forklift types. The straight fork is called the balance heavy, its cargo fork in the front of the forklift. Due to the pallet fork out outside the front wheel axis, the overturning moment, in order to balance the goods weight in the rear part of the forklift truck is equipped with a counterweight, to maintain stability of forklift. Side fork lift truck: its cargo fork is on the side of the forklift truck.

- Q: Special equipment, the type of vehicle for forklift licence and corresponding driving vehicle

- The N2 forklift card can drive a forklift: 1, there is no limit to the type of driving car, and the tonnage can be opened. 2, short for "motor vehicle driving license", and "driving licence", in accordance with the law personnel required for motor vehicle driving licenses, previously known as forklift driver, now change to code, forklift driver code is N2. 3. The forklift driving is special operations, issued by the state production safety supervision and administration of the People's Republic of China special operations card ", forklift, generally are tools, only used in the unit within the work place. So generally speaking, you only need a position certificate or a license, but the average unit will ask for a driver's license.

- Q: Can a power supply of 48-volt battery pack a 12 volt fan

- Is it a dc fan? If that's the case, use a decompression module and estimate a few dollars to a dozen or so. If the 48V is composed of a 12-volt battery pack, then the two lines will be straight forward

- Q: What oil do you use for forklift

- Brand choice, must choose big brand, its quality is generally more secure, be like the world four big brands: mobil, BP, shell and total; Two big domestic brands: Great Wall and kunlun

- Q: What type of work is the forklift worker in the new labor law

- You should look at you with the original state-owned enterprises to sign labor contract, time to what time, if the contract did not end, unit of choose and employ persons cannot be unilaterally change.

Send your message to us

3.5 Tons Diesel Powered Forklift CPCD35FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords