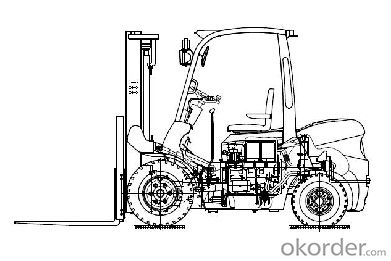

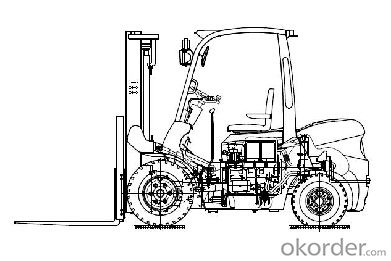

2 Tons Diesel Powered Forklift product CPCD20FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

Forklift Specification:

Model | CPCD20FR | |

Load capacity kg | 2000kg | |

Load center mm | 500mm | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 400mm/s | |

Max.Driving speeds(with without load) km/h | 17/19km/h | |

Max.Towing speeds | 14/9kN | |

(with/without load)kN | ||

Gradeability(with/without load)% | 15/20% | |

H1 Lifting height mm | 3000mm | |

Free lift mm | 60mm | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 2450mm | |

Min. right angle aisle width mm | 2050mm | |

Min. under-clearance mm | 110mm | |

Dimensions | A Overall length(inincluding fork) mm | 3605mm |

B Overall width mm | 1160mm | |

H Overall height(mast lowered) mm | 2095mm | |

H2 Overall height (mast extend) mm | 4080mm | |

H3 Overall height to overhead guard mm | 2095mm | |

A1 Fork overhang mm | 451mm | |

A2 Wheel base mm | 1640mm | |

Tread | B1 Front tread mm | 970mm |

B2 Rear tread mm | 970mm | |

Tyre | Front tyre | 7.00-12 |

Rear tyre | 6.00-9 | |

Total weight kg | 3320kg | |

B3 Fork width mm | ||

H4 Fork thickness mm | 40mm | |

Backrest height mm | ||

A3 Fork length mm | 1070mm | |

Engine | Engine model | 490 |

Rate power KW | 39KW | |

Rotate Speed At Rate Power rpm | 2650rpm | |

Max.torque Nm | 157Nm | |

Rotate speed at max torque rpm | 1980rpm | |

Type of power shift | Hydraulic | |

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: What is the responsibility of the forklift driver for the job?

- If the driver of a forklift truck is employed, the unit shall be liable for compensation. If the driver of a forklift is employed by an individual, the employer shall bear the liability for compensation. The two sides may negotiate a compensation dispute in advance and fail to bring a suit to the court.

- Q: How do you use the gta5 forklift, the one that carries the container on the dock

- Then press CTRL to push the arm to the container and press E.I hope my answer is useful to you.

- Q: Battery lift truck charging requirement

- The battery produces a gas during the charging process and should be kept well ventilated and there is no open fire. 4, in any case, in the process of charging the electrolyte temperature should not exceed 45 ℃, otherwise should try to cool down, such as to reduce the charging current, measures such as artificial cooling or pause charge, after waiting for the temperature drop charge again. It is strictly forbidden to put metal tools on the battery. There is no excess clutter on the battery.

- Q: Is it dangerous to drive a forklift?

- Some! As far as I know forklift is dangerous, maybe you haven't contact with the line, or contact time is not long, I experience that once I driving forklift fast and then a sharp turn, forklift nearly doubled, at that time if it weren't for reflect the fast, I'm afraid his life did not have. Another time I looked at a colleague who was pushing a woman to death when he turned from the door. So you have to be careful about driving a forklift. Work 3-4 hours and you will feel mentally paralyzed, especially in the middle of the summer, so drive a forklift must be focused

- Q: Is the stack a forklift truck

- Stacking machine is fixed assets to stack up the goods, and can take down a mechanical device, but can not be called a forklift, because although there are a fork forklift, but it is a car. Stacking machine is not a car.

- Q: How to drive a forklift? Detailed point!

- I brief said how to reverse it, like a reverse must correct posture, some forklift at the back of the seat with wings, the wings is a normal protect drivers, and there's a role in reversing, convenient pilot operations back to the pilot a support, if there is no the gussets drivers will produce insecurity, as Toyota forklift its design concept is at the top of the protective right rear has a handle, his work on the role of the wings are the same as above, need to hang on to the steering wheel, then left hand grasp the driving direction,

- Q: Special equipment, the type of vehicle for forklift licence and corresponding driving vehicle

- The forklift truck needs to pass the learning examination to obtain the N2 special equipment operator issued by the quality supervision bureau to be able to drive

- Q: What happens when you do the force forklift

- If it's a manual, it could be a disjoint. Or pressure plate.Your car (dangling from side to side of the wheel) is supposed to be the shaft of the door.

- Q: What is a forklift worker

- First know what a forklift is, and the driver of this car is a forklift 1. An overview of the The forklift truck is designed for handling goods and short distances, the main lifting device is a fork, and can be fitted with various types of equipment. This forklift is best suited for smooth, hard surfaces (asphalt, cement, etc.). Used for loading and unloading of warehouse, railway station, shipping dock, construction site, etc., which can reduce the labor intensity of staff and improve the efficiency of loading and unloading.

- Q: I want to learn about the forklift truck. I don't know how well the forklift man works.

- Find a job that is easy to find, and go to the feed factory. At least 3,500 in January, there are five to six thousand, and I did it at the feed factory. You can also go to the electronics factory, but the salary may be more than 3, 000, but it's fun and easy. The answer can help a friend's words, thanks

Send your message to us

2 Tons Diesel Powered Forklift product CPCD20FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords