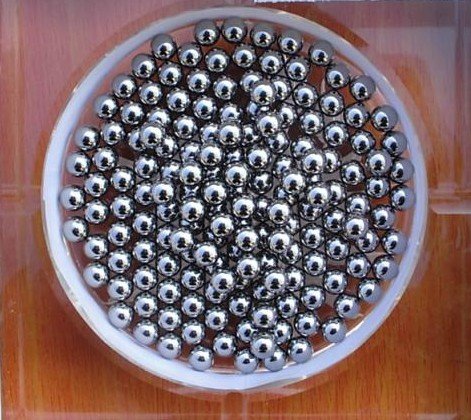

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Ball

MAIN PRODUCTS:

1. Material: AISI304, 316L, 420C, 430, 440C

2. Steel ball, with material AISI 1008-1086.

3. Chrome steel ball,with material: AISI52100

4. Flying saucer steel ball

5. Precision casting, including auto parts, machine parts, hardware handles, etc.

CHARACTER OF PRODUCTS:

1.The Grade of our products is from G10 to G1000

2.The dimension is from 0.5 mm to 25.4 mm.

3.The products from us are widely used in several industries, such as hardware, sliders, ball bearing lead screw, wheels, toys, bicycles, bearings, trust bearings pulleys, chemical industries, etc.

DETAIL SPECIFICATION:

|

Item |

SS304,316L,420C,440C Stainless steel ball |

|

Category |

Stainless Steel Ball |

|

Material |

AISI 420 430 440 SS304 316L |

|

Size |

0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

|

Grade |

G100-G3000 |

|

Hardness ( HRC) |

HRC58-65 |

|

Application |

Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

|

Standard |

GB/T-308-2002, GB/T1148-93 |

|

Matched Standard |

DIN, JIS, ASME |

|

Certification |

ISO |

|

Packing |

Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

|

Place of original |

Shandong province, China |

|

Delivery |

Within 30 days or confirmed while placing order |

- Q: Can stainless steel balls be used in abrasive environments?

- Yes, stainless steel balls can be used in abrasive environments. Stainless steel is known for its excellent corrosion resistance and durability, making it suitable for various abrasive environments. Its resistance to rust and corrosion allows stainless steel balls to withstand harsh conditions, including exposure to abrasive materials or substances. Additionally, stainless steel is also resistant to high temperatures, making it a reliable choice for applications in abrasive environments. Its hardness and strength properties ensure that stainless steel balls can effectively handle the impact and wear caused by abrasive materials, making them a popular choice in industries such as mining, construction, and chemical processing.

- Q: Are stainless steel balls suitable for high-precision measuring instruments?

- Yes, stainless steel balls are suitable for high-precision measuring instruments. Stainless steel is known for its excellent corrosion resistance, durability, and dimensional stability, making it an ideal material for precision applications. Stainless steel balls can be manufactured with tight tolerances and high surface finishes, ensuring accurate and precise measurements. They are commonly used in applications such as ball bearings, check valves, gauging and measuring instruments, and other precision equipment where consistent and reliable measurements are crucial. Additionally, stainless steel balls are non-magnetic, which is important in some measuring instruments where magnetic interference could affect accuracy. Overall, stainless steel balls are a reliable choice for high-precision measuring instruments due to their properties and performance characteristics.

- Q: Can stainless steel balls be used in ball valves or other types of valves?

- Yes, stainless steel balls can be used in ball valves as well as other types of valves. Stainless steel is a commonly used material for valve components due to its excellent corrosion resistance and durability. Stainless steel balls are particularly suitable for applications where there is a need for resistance to chemical or environmental corrosion. They are often used in ball valves to provide a tight seal and smooth operation. Additionally, stainless steel balls can withstand high temperatures, making them suitable for various industrial processes. Overall, stainless steel balls are a versatile option for valve applications and are widely used in the industry.

- Q: Are stainless steel balls used in paint mixing?

- Yes, stainless steel balls are commonly used in paint mixing processes. They are added to paint cans or containers to aid in the thorough mixing of pigments and other components, ensuring uniformity and consistency in the paint.

- Q: Are stainless steel balls suitable for automotive engine components?

- Yes, stainless steel balls are suitable for automotive engine components due to their excellent corrosion resistance, high temperature resistance, and durability. They can be used in various engine components such as valves, bearings, and fuel injectors, providing reliable performance and longevity.

- Q: What are the cost advantages of using stainless steel balls?

- There are several cost advantages of using stainless steel balls. Firstly, stainless steel is highly durable and resistant to corrosion, which means the balls have a longer lifespan compared to other materials. This reduces the need for frequent replacements and maintenance, resulting in cost savings over time. Additionally, stainless steel balls have high wear resistance, minimizing the risk of damage or deformation during use. This further contributes to their longevity and reduces replacement costs. Furthermore, stainless steel balls are readily available in the market, making them more cost-effective compared to specialized or rare materials. Overall, the cost advantages of using stainless steel balls lie in their durability, low maintenance requirements, wear resistance, and affordability.

- Q: What are the different types of stainless steel ball bearings?

- On the market, you can find various stainless steel ball bearings, each with its own characteristics. These bearings can be distinguished based on their composition, design, and specific application needs. 1. Austenitic Stainless Steel Ball Bearings: These bearings are crafted from austenitic stainless steel, a material that is non-magnetic and highly resistant to corrosion. They are commonly used in industries such as food processing, medical equipment, and marine applications, where resistance to chemicals, moisture, and high temperatures is essential. 2. Martensitic Stainless Steel Ball Bearings: Martensitic stainless steel bearings are renowned for their exceptional strength and hardness. With a martensitic crystal structure, they provide excellent durability and wear resistance. These bearings are commonly employed in heavy machinery, automotive components, and power transmission systems, where high loads and abrasive environments are prevalent. 3. Duplex Stainless Steel Ball Bearings: Duplex stainless steel bearings are a combination of austenitic and ferritic stainless steels, offering a unique balance of strength, corrosion resistance, and toughness. They are suitable for applications requiring high mechanical strength and resistance to pitting and crevice corrosion, making them ideal for the oil and gas, chemical processing, and pulp and paper industries. 4. Precipitation Hardening Stainless Steel Ball Bearings: These bearings undergo a heat treatment process to enhance their strength and hardness. As a result, they offer excellent corrosion resistance, high wear resistance, and dimensional stability. They are commonly found in industries that demand high precision, such as aerospace, defense, and automotive. 5. High-Temperature Stainless Steel Ball Bearings: These bearings are made from stainless steel alloys capable of withstanding elevated temperatures without compromising their mechanical properties. They possess excellent heat resistance and are suitable for extreme temperature environments, such as ovens, furnaces, and turbochargers. Choosing the appropriate stainless steel ball bearing for your specific application is crucial. Factors to consider include load capacity, speed, temperature, and environmental conditions. Seeking guidance from a bearing manufacturer or supplier can help you select the most suitable stainless steel ball bearing for your requirements.

- Q: Are there any standards or certifications for stainless steel balls?

- Yes, there are several standards and certifications for stainless steel balls. The most common ones include ISO 3290, ASTM International, and the European Standard EN 10088. These standards ensure that stainless steel balls meet specific requirements for material composition, dimensions, surface quality, and mechanical properties. Additionally, certifications such as ISO 9001 and ISO 14001 may also be obtained by manufacturers to demonstrate their adherence to quality and environmental management systems.

- Q: Are stainless steel balls suitable for use in marine environments?

- Indeed, stainless steel balls prove to be a fitting option for utilization in marine settings. Renowned for its exceptional resistance to corrosion, stainless steel showcases remarkable capability in warding off rust and other forms of corrosion induced by moisture and saltwater exposure. Consequently, stainless steel balls present an optimal selection for a multitude of marine applications, including valves, pumps, bearings, and various machinery components. Moreover, stainless steel possesses notable strength and durability, enabling it to endure the demanding conditions and impacts frequently encountered in marine environments. As a result, stainless steel balls deliver dependable performance and longevity when utilized in marine settings, rendering them a suitable preference for deployment in such surroundings.

- Q: Are stainless steel balls used in aerospace gyroscopes?

- Yes, stainless steel balls are commonly used in aerospace gyroscopes. Gyroscopes are essential components in aerospace applications as they provide stability and help in maintaining orientation and navigation. Stainless steel balls are preferred in these gyroscopes due to their high strength, corrosion resistance, and durability. They are capable of withstanding harsh environments, high temperatures, and extreme pressures that can be encountered in aerospace operations. Additionally, stainless steel balls offer excellent dimensional accuracy, low friction, and high precision, which are crucial for the smooth functioning of gyroscopes in aerospace applications.

1. Manufacturer Overview

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords