4130 30CrMo SCM430 Alloy Structure Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Product Description of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

1. Steel grade: ASTM4140, SCM440, 42CrMo, DIN1.7225

2. Length: 6M-12M

3. Diameter: 16mm-300mm

4. Product range: round bar, flat bar, square bar

5. Technique: Hot rolled, forged, cold drawn

Specification of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Material | SCM4140 | Round bar | Dia(mm) | 16-300mm |

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12m | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500mm |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200mm | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12m |

Chemical Composition of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

C | Si | Mn | Cr | Mo | P | S |

0.38~0.43 | 0.15~0.35 | 0.75~1.00 | 0.8~1.1 | 0.15~0.25 | ≤0.035 | <0.04< td=""> |

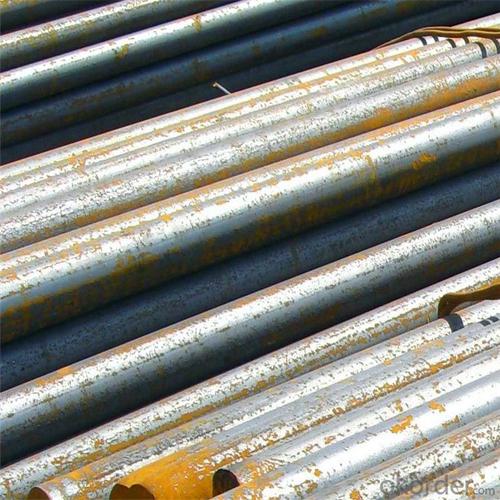

Photo Show of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Packing and Delivery:

Packing in bundle package, or as customer's requirements.

Delivery Detail: 45 days after receiving the deposit.

Usage and Applications of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some special material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Are steel round bars suitable for use in the construction industry?

- Yes, steel round bars are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support in various applications such as reinforcement in concrete, framing, and the creation of beams and columns. Additionally, steel round bars can be easily fabricated, welded, and formed into different shapes, making them a suitable choice for a wide range of construction projects.

- Q: How do steel round bars differ from other types of steel bars?

- Steel round bars differ from other types of steel bars primarily in their shape and versatility. Unlike other steel bars such as square or flat bars, steel round bars are cylindrical in shape and have a circular cross-section. This unique shape allows for greater flexibility and adaptability in their usage. One of the main advantages of steel round bars is their ability to withstand high levels of stress and pressure. Due to their circular shape, they distribute weight and pressure evenly, making them ideal for applications that require durability and strength. These bars are often used in construction, manufacturing, and engineering projects where structural integrity is crucial. Another key difference is the ease with which steel round bars can be machined and manipulated. Their cylindrical shape allows for easy drilling, cutting, and shaping, making them highly versatile and suitable for a wide range of applications. They can be easily welded, bent, or formed into various shapes, giving them an advantage over other types of steel bars in terms of customization. In terms of appearance, steel round bars also have a distinct visual appeal. The smooth and cylindrical surface of these bars offers a sleek and polished look, making them aesthetically pleasing in architectural and decorative applications. Overall, steel round bars stand out from other types of steel bars due to their shape, versatility, and strength. Their ability to withstand high levels of stress, ease of machining, and appealing appearance make them a popular choice in various industries.

- Q: Are steel and round steel the same thing?

- Round steel is a solid strip of steel whose cross section is round. Its specifications are expressed in diameter, in units of millimeters (mm), such as "50mm", which means a diameter of 50 millimeters of round steel.

- Q: How do you straighten a bent steel round bar?

- To straighten a bent steel round bar, you can use either a hydraulic press or a mechanical straightening machine. The process involves applying gradual pressure to the bent area until it becomes straight again. It is important to ensure even pressure distribution to avoid further damage to the bar.

- Q: What are the different types of steel round bars used in the agricultural sector?

- In the agricultural sector, there are several types of steel round bars that are commonly used due to their strength, durability, and versatility. These bars play a crucial role in various agricultural applications. 1. Mild Steel Round Bars: Mild steel is one of the most widely used types of steel in the agricultural sector. It offers excellent strength and is relatively low in cost. Mild steel round bars are commonly used in the construction of agricultural equipment, such as plows, cultivators, and harrows. 2. Carbon Steel Round Bars: Carbon steel round bars are known for their high strength and toughness. They can withstand heavy loads and are ideal for applications that require superior durability. Carbon steel round bars are commonly used in the manufacturing of tractor parts, tillage tools, and other heavy-duty agricultural machinery. 3. Alloy Steel Round Bars: Alloy steel round bars are made by adding various alloying elements to steel, such as chromium, nickel, or molybdenum. These elements enhance the strength, hardness, and corrosion resistance of the steel. In the agricultural sector, alloy steel round bars are often used in the manufacturing of high-performance components, such as gears, axles, and shafts. 4. Stainless Steel Round Bars: Stainless steel round bars are highly resistant to corrosion and have excellent mechanical properties. They are commonly used in agricultural applications that require resistance to moisture, chemicals, and harsh environments. Stainless steel round bars are often utilized in the manufacturing of dairy equipment, storage tanks, and irrigation systems. 5. Tool Steel Round Bars: Tool steel round bars are specifically designed to withstand high temperatures, abrasion, and impact. They are used in agricultural applications that involve cutting, shaping, or drilling. Tool steel round bars are commonly used in the production of blades, cutting tools, and machinery parts for crop harvesting and processing. It is important to consider the specific requirements and conditions of each agricultural application when selecting the appropriate type of steel round bar. By choosing the right steel round bar, farmers and agricultural professionals can ensure the reliability and longevity of their equipment and machinery.

- Q: What are the advantages of using nickel-copper alloy steel round bars?

- There are several advantages of using nickel-copper alloy steel round bars. Firstly, nickel-copper alloy steel has excellent resistance to corrosion and oxidation. This makes it ideal for applications in harsh environments, such as marine or chemical industries, where the bars may come into contact with corrosive substances or saltwater. The high resistance to corrosion ensures the longevity and durability of the round bars, reducing the need for frequent replacements. Secondly, nickel-copper alloy steel round bars have excellent mechanical properties. The addition of nickel and copper to the alloy enhances its strength, toughness, and hardness. This makes the bars suitable for heavy-duty applications that require high strength and durability, such as in construction, manufacturing, and engineering. The superior mechanical properties of nickel-copper alloy steel round bars allow them to withstand heavy loads and resist deformation or breakage, contributing to the overall safety and reliability of the structures or components they are used in. Another advantage of using nickel-copper alloy steel round bars is their excellent thermal stability. The alloy has a low coefficient of thermal expansion, meaning it can withstand high temperatures without significant dimensional changes. This property is particularly important in applications that involve exposure to extreme heat, such as in the aerospace or power generation industries. The thermal stability of the round bars ensures their dimensional integrity, reducing the risk of warping or cracking under high-temperature conditions. Furthermore, nickel-copper alloy steel round bars offer good electrical conductivity. This property is beneficial in applications that require the transmission of electric current, such as in electrical wiring or power distribution systems. The high electrical conductivity of the alloy ensures efficient and reliable electrical connections, minimizing power loss and maximizing performance. In conclusion, the advantages of using nickel-copper alloy steel round bars include excellent corrosion resistance, superior mechanical properties, thermal stability, and good electrical conductivity. These characteristics make the bars suitable for a wide range of applications in various industries, providing durability, strength, and reliability.

- Q: What is the corrosion resistance of steel round bars?

- The corrosion resistance of steel round bars depends on the type of steel and the environmental conditions they are exposed to. Generally, stainless steel round bars offer excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier, preventing further corrosion from occurring. However, carbon steel round bars are more susceptible to corrosion, especially in environments with high moisture or exposure to corrosive substances. In these cases, additional protective measures such as coatings or galvanizing may be required to enhance their corrosion resistance. It's important to note that the performance of steel round bars in corrosive environments also depends on various factors like temperature, pH level, and the presence of other elements or chemicals. Therefore, it is recommended to consider the specific application and consult with corrosion experts to determine the most suitable steel grade and corrosion protection measures for your needs.

- Q: What are the different grades of tool steel round bars?

- Tool steel round bars are available in various grades, each offering unique properties and characteristics to suit specific applications. Some of the different grades of tool steel round bars include: 1. W1: This is a water-hardening tool steel with relatively low carbon content. It is known for its excellent toughness and good wear resistance. W1 tool steel round bars are commonly used for cutting tools and woodworking tools. 2. O1: O1 tool steel round bars are oil-hardening tool steel with high carbon content. They have good wear resistance, high toughness, and excellent dimensional stability. O1 tool steel is often used for punches, dies, and cutting tools. 3. A2: A2 tool steel round bars are air-hardening tool steel with medium carbon and chromium content. They offer good wear resistance, excellent toughness, and high dimensional stability. A2 tool steel is commonly used for blanking and forming dies, as well as shear blades. 4. D2: D2 tool steel round bars are high-carbon, high-chromium tool steel with excellent wear resistance and good toughness. They offer high resistance to abrasive wear and are often used for making cutting tools, punches, and forming dies. 5. M2: M2 tool steel round bars are high-speed steel with a significant amount of tungsten, molybdenum, and vanadium. They have exceptional wear resistance, high red hardness, and good toughness. M2 tool steel is typically used for high-speed cutting tools, drill bits, and machining tools. 6. S7: S7 tool steel round bars are air-hardening shock-resistant tool steel. They have high impact toughness, good wear resistance, and excellent heat resistance. S7 tool steel is commonly used for applications that require high shock resistance, such as chisels and hammers. These are just a few examples of the different grades of tool steel round bars available in the market. The choice of grade depends on factors such as the specific application, desired hardness, wear resistance, toughness, and heat resistance required. It is important to consult with a knowledgeable supplier or metallurgist to determine the most suitable grade for a particular application.

- Q: What are the common industries that use steel round bars?

- Steel round bars are widely used in various industries due to their strength, durability, and versatility. Some of the common industries that heavily rely on steel round bars include construction, manufacturing, automotive, aerospace, energy, and oil and gas. In the construction industry, steel round bars are commonly used in the creation of structural frameworks, such as beams, columns, and trusses. They provide the necessary support and stability required for buildings, bridges, and other infrastructures. Additionally, steel round bars are utilized in reinforcement applications, such as concrete reinforcement bars (rebars), ensuring the structural integrity of various construction projects. The manufacturing industry also extensively utilizes steel round bars for the production of machinery, equipment, and tools. These round bars are often machined, forged, or heat-treated to create components like shafts, gears, fasteners, and bearings. Due to their high tensile strength and resistance to wear and tear, steel round bars are ideal for withstanding heavy loads and harsh operating conditions. In the automotive sector, steel round bars are employed in the manufacturing of various vehicle components, including axles, crankshafts, camshafts, and suspension systems. The use of steel round bars in these critical parts ensures the necessary strength and durability required for safe and reliable transportation. The aerospace industry heavily relies on steel round bars for the production of aircraft components. From landing gear to engine parts and structural elements, steel round bars are essential in ensuring the safety and performance of aircraft. The high strength-to-weight ratio of steel makes it an ideal material for aerospace applications, as it allows for lighter aircraft without compromising strength. Furthermore, the energy industry, including power generation and transmission, utilizes steel round bars in the construction of turbines, generators, and transmission towers. The robustness and corrosion resistance of steel make it suitable for withstanding extreme temperatures and harsh environments. Lastly, the oil and gas industry extensively uses steel round bars for drilling equipment, pipe fittings, valves, and other critical components. These round bars are required to withstand high-pressure and corrosive environments, making them essential for oil and gas exploration, extraction, and transportation. In conclusion, steel round bars find application in a wide range of industries, including construction, manufacturing, automotive, aerospace, energy, and oil and gas. Their strength, durability, and versatility make them a preferred choice for various applications, ensuring the safety, reliability, and efficiency of numerous industrial processes.

- Q: What is the maximum nitrogen content allowed for steel round bars?

- The maximum nitrogen content allowed for steel round bars varies depending on the specific steel grade and application requirements. However, in general, the nitrogen content is typically limited to around 0.025-0.035% to maintain the desired mechanical properties and avoid detrimental effects on the material's performance.

Send your message to us

4130 30CrMo SCM430 Alloy Structure Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords