4.0 China best-selling fireproof glass insulating insulating glass public places fireproof glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Factory Wholesale Customized 3Mm 4Mm 8Mm 12Mm Fireproof Heatproof

Fireproof Glass Advantages:

Our top quality fire-proof glass is widely used for luxury hotel, theater, exhibition hall, airports, gymnasium,hospital,

commercial building and other public building. And all our fire-proof glass has the following features:

(1) Fire-resistance: fire-proof glass can keep down the spread of fire effectively;

(2) Safety: If it is broken, it usually breaks into relatively small pieces, which are less likely to cause serious injury;

(3) High temperature resistance:Fire-proof glass can endure more than 300°C temperature

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

The factory mainly produces

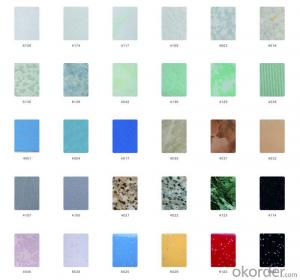

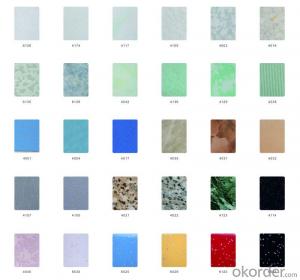

Borosilicate 4.0 fireproof glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 4.0 fireproof glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

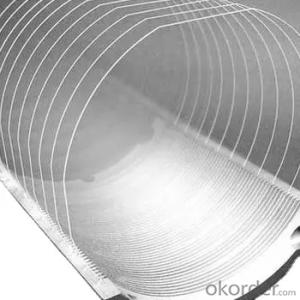

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Which industry people, to help return to the final decision to do with the tax treasure Japonica ah, refractory materials and fireproof materials like it? I intend to do an industry website, do not know whether the refractory material and fireproof material more conflict

- Refractory materials and fireproof materials are all building materials industry, to do a single industry can, for example, you said the refractory or fireproof material

- Q: The fire resistance of building materials includes the nature of building materials

- The burning performance of a building material refers to all physical and chemical changes that occur during combustion or fire, which is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity Produce and other characteristics to measure. China's national standard GB8624-97 will be the burning of building materials into the following grades. Class A: Noncombustible Building Materials B1 Grade: Flammable Building Materials Grade B2: Flammable Building Materials B3 Grade: Flammable Buildings Lawyers Unrestricted Karma Karma Stuck But Stem Material Section 2 Combustion Performance and Fire Resistance of Building Components limit

- Q: Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- The key depends on the appearance of the cut off the preparation of how to deal with. If the appearance of the surface to be directly brushing latex paint, then directly with the wooden keel frame, and then seal the gypsum board can be, and if you hang the TV, when the framework, in the appropriate location fixed a large core board, Gypsum board is to withstand the TV) If the appearance of the facade to think about the paint, then use the wooden keel to do the framework, and then Daixinban substrate, do the decorative panels, and finally do paint. Advantages and disadvantages of fire board: 1, fire board, that is, we usually heard in the life of the fire board, usually the use of kraft paper or titanium powder in the phenolic resin and melamine impregnated under high temperature after the pressure made of a Plate type, belonging to a refractory building materials. Its insulation, heat insulation is six times the glass, clay three times, ordinary concrete ten times. 2, ALC board is a silicate material, there is no aging problem, it is not easy weathering, is a durable building materials, the normal life and all kinds of permanent buildings can match the life span. 3, ALC board is not radioactive, there is no harmful substances spill. Aerated concrete fire board superiority: in the production process, there is no pollution and hazardous waste generated. When used, there is no radioactive material and harmful gases, even at high temperatures and in the fire. Each of the independent micro-bubbles, so that aerated concrete products have a certain impermeability, to prevent water and gas penetration, green.

- Q: Performance and Difference of Rockwool and Glass Fiber Fireproof Materials

- Rock wool and glass wool fire rating are all A-level rock wool high temperature of 800 degrees glass wool high temperature 450 touch tiger whip mortar Zhuang Huan Biao cloth wave density rock wool relative weight of some glass wool bulk light from the waterproof performance or glass wool better some

- Q: What are the building materials, building materials, and interior decoration materials with fire resistance? Can be specific point!

- Each material has its own fire rating, and some hours, there are three hours, so divided into C-class C fireproof material

- Q: If not expensive to buy one of the best, but OKorder did not find. Because I have some important documents, documents, money, worry about living somewhere a day of fire. In case, I would like to put these important objects inside the bag can be fire. Not much of a thing, a folder size of the bag is enough. What materials can be used to make one way? Can also wrap the line, but can often open, not like the tape that ridge set up the plateau dry chop suck raft by the sample sealed. Thank you. More

- I can do you can give me a message that we simply talk about my product at 3000 degrees high temperature is no problem, and carry with no problems, heavy ridge set up the plateau dry chop sucking raft by the volume is also light, easy to keep.

- Q: Fire safety knowledge

- Fire ruthless, in the event of a fire, the students want to keep a clear head, race against time, quickly leave. If the fire was besieged, but also to be contingent, trying to escape. (A), how to escape the cottage fire 1, sleep when the smoke to wake up, should quickly get out of bed leaning out of the room. Do not wait for the clothes to run out, the moment is life. 2, if the whole house fire, to crawl crawling into the door, it is best to find a wet towel cover your nose and mouth. If the fireworks closed, do not go out! Should be changed to other exports, and readily put you through the doors and windows closed to delay the spread of the fire to other rooms. 3, if you are surrounded by fireworks in the house, the application of water wet blankets or bedding, put it on the body, in particular, to wrap the head, with a wet towel Mongolian live nose, do protective measures and then rushed out, so The odds of injury are much smaller. 4, do not lie under the bed, under the table or drill into the closet hiding. And do not risk the return of the burning room for the relief of the valuables at home.

- Q: Wood-plastic material fire?

- Fire rating is classified. Can not simply say that wood-plastic material fire or not. According to the composition of wood-plastic materials, which is mainly plastic and wood powder, in order to increase the fire resistance of wood-plastic, plus a certain amount of flame retardants, but the type and number of flame retardants and a direct impact on the fire for the box The performance of the valley. At present, many wood-plastic materials, the highest level of fire should be in the B1 level, the need for a stronger fire rating, then the need for special formula, many companies can not do a class A fire rating. Detailed advice ::...

- Q: What are the fireproof materials for Class A roof insulation?

- At present, only phenolic board can meet the requirements, the test temperature of 2000 degrees, no droplets, good integrity. The thermal conductivity of non-combustible, non-toxic, smoke-free!

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Belong to the flammable material is absolutely can not be used in the ceiling, to use the flame retardant material Caixing, fire technical specifications are required.

Send your message to us

4.0 China best-selling fireproof glass insulating insulating glass public places fireproof glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches