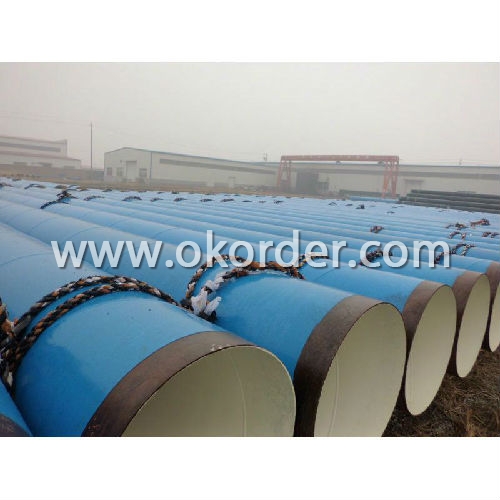

3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

order | item | performance | test method. | |

2PE | 3PE | |||

1 | peeling strength (N/cm)20±5℃ 50±5℃ | ≥35 ≥25 | ≥60 ≥40 | DIN30670 |

2 | cathodic disbanding(mm) (65℃,48h) | ≤15 | ≤10 | SY/T4013 |

3 | impact strength (J/mm) | ≥8 | DIN30670 | |

4 |

bending resistant (2.5°) | No cracking of polyethylene | SY/T4013 | |

5 | Pinhole (25kv) | No leak | DIN30670 | |

Specification of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

1.Materials Q235 Q345 ect.

2.Length Less than 18m

3.Thickness 5-30mm

4.Trade terms CIF CFR FOB

5.API GB/T DIN ect

Package and Delivery of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

Package:Marking ,Black painting , Bevel end ,Plasitc Cap .

Delivery:30-60days

Applications of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment, aviation, boiler heat, exchanger, gas metallurgy, shipbuilding

Others of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

1.Special design available according to requirement

2.anti-corrosion and high-temperature resistant with black painting

3. All the production process are made under the ISO9001:2000 strictly.

At present, our company can undertake various external coating project fro steel pipes, like single or two-layer fusion bonded epoxy power FBE, 2PE, 3PE, 2PP, or other corrosion coating is used for them. We also can apply for the internal coating of cement Mortar inner wall pipeline. It can also undertake applications of anti-corrosion coatings and thermo-isolation cover for various metal storage tanks, metal vessel and other metal structure.

- Q: What are the factors that affect the price of steel pipes?

- There are several factors that can affect the price of steel pipes. Some of the key factors include the cost of raw materials such as iron ore and steel scrap, market demand and supply dynamics, production and transportation costs, tariffs and trade policies, currency exchange rates, and overall economic conditions. Additionally, factors like technological advancements, environmental regulations, and changes in industry standards can also impact the pricing of steel pipes.

- Q: What are the advantages of using steel pipes in irrigation systems?

- There are several advantages of using steel pipes in irrigation systems. Firstly, steel pipes are highly durable and can withstand harsh weather conditions and heavy loads, ensuring a long lifespan. Secondly, they have a high tensile strength, which means they can handle high pressure and water flow rates without the risk of bursting or leaking. Additionally, steel pipes are resistant to corrosion, which is crucial for maintaining water quality and preventing contamination. Lastly, steel pipes are easy to install and maintain, making them cost-effective in the long run.

- Q: What are the different strategies for pipe laying using steel pipes?

- There are several strategies for pipe laying using steel pipes, each suited for different environments and requirements. Here are some of the commonly used strategies: 1. Open Trench: This is the most traditional and widely used method, where a trench is dug along the desired pipeline route. Steel pipes are then laid in the trench, aligned, and welded together. This method allows for easy access, maintenance, and repair of the pipeline. 2. Direct Pipe: This method is used when there are crossings under obstacles such as rivers or highways. It involves drilling a borehole from one side to the other, while simultaneously laying the steel pipe. The pipe is then pulled through the borehole, creating a continuous pipeline. 3. Horizontal Directional Drilling (HDD): HDD is employed when the pipeline needs to be installed under existing infrastructure or environmentally sensitive areas. A pilot hole is drilled horizontally, and the steel pipe is then pulled through the hole using a reaming tool. This technique minimizes disruption to the surface and reduces environmental impact. 4. Sliplining: Sliplining involves inserting a smaller diameter steel pipe into an existing larger pipe. The smaller pipe is pushed or pulled into the larger pipe, providing a new corrosion-resistant lining. This method is commonly used for rehabilitating deteriorated or damaged pipelines. 5. Microtunneling: Microtunneling is similar to HDD, but it involves a microtunnel boring machine (MTBM) that excavates the soil and installs the steel pipe simultaneously. This method is often used for precision pipe laying, especially in urban areas with limited space. 6. Jacking: Jacking, also known as pipe jacking or pipe ramming, is utilized for installing steel pipes in soil conditions that are not suitable for open trenching. This method involves pushing the steel pipe into the ground using hydraulic jacks or pneumatic rams. It is commonly used for crossing under railways, roads, or buildings. 7. Offshore Pipeline Laying: For subsea applications, steel pipes can be laid using a variety of techniques, such as S-lay, J-lay, or reel-lay. These methods involve deploying the pipeline from a vessel, either vertically or at an inclined angle, and welding the steel pipes together as they are lowered to the seabed. Each of these strategies has its own advantages and considerations, depending on factors such as terrain, environmental impact, existing infrastructure, and project requirements. It is important to carefully evaluate these factors and select the most suitable pipe laying strategy to ensure the safe and efficient installation of steel pipes.

- Q: Can steel pipes be used for conveying sewage and wastewater?

- Indeed, sewage and wastewater can be conveyed using steel pipes. The use of steel pipes is widespread in sewage and wastewater systems owing to their robustness and resilience. They possess corrosion resistance and can endure immense pressure and flow rates. Moreover, steel pipes have the capability to manage the rigorous chemicals and pollutants found in sewage and wastewater without impairing or compromising the fluid quality. Nonetheless, it is crucial to guarantee proper coating or lining of the steel pipes to avert any potential problems concerning corrosion or contamination. Regular maintenance and inspections are equally important to detect and rectify any potential concerns that may arise within the system.

- Q: What is the average lead time for manufacturing steel pipes?

- The average lead time for manufacturing steel pipes can vary depending on several factors such as the size and complexity of the order, production capacity, and current demand. However, it typically ranges from a few weeks to a few months.

- Q: How are steel pipes insulated to prevent heat gain?

- Steel pipes are insulated to prevent heat gain by applying a layer of thermal insulation material around them. This insulation material acts as a barrier, preventing the transfer of heat from the surrounding environment to the steel pipes. Additionally, the insulation is often covered with a protective outer layer to enhance its durability and resistance to external factors.

- Q: What is the thermal expansion coefficient of steel pipes?

- The thermal expansion coefficient of steel pipes varies depending on the specific type of steel used, as well as the temperature range in which the expansion is being measured. However, on average, the thermal expansion coefficient of steel pipes ranges from 10-14 x 10^-6 per degree Celsius (10-14 μm/m°C). This means that for every degree Celsius increase in temperature, the length of a steel pipe will expand by approximately 10-14 μm per meter of length. It is important to note that this value is an average and can vary slightly depending on the specific composition and treatment of the steel used in the pipe.

- Q: Are steel pipes more expensive than other types of pipes?

- Steel pipes can be more expensive than other types of pipes, but this can vary depending on various factors such as the size, grade, and specific application requirements.

- Q: How are steel pipes used in geothermal energy systems?

- Steel pipes are commonly used in geothermal energy systems to facilitate the transport of fluids, such as water or steam, between the geothermal source and the power plant. These pipes are designed to withstand high temperatures and pressures, ensuring the safe and efficient transfer of geothermal fluids. Additionally, steel pipes are used in the construction of geothermal wells, providing structural support and maintaining the integrity of the wellbore.

- Q: What are the safety precautions to follow when working with steel pipes?

- To guarantee the safety of yourself and those around you while working with steel pipes, it is crucial to adhere to a number of safety measures. These measures encompass the following: 1. Personal Protective Equipment (PPE): It is imperative to always wear the appropriate PPE when dealing with steel pipes. This includes safety glasses, gloves, steel-toed boots, and a hard hat. By utilizing PPE, you can shield yourself from potential hazards such as flying debris, falling objects, and sharp edges. 2. Proper Lifting Techniques: Given that steel pipes can be heavy and unwieldy, it is essential to employ proper lifting techniques to avoid strain or injury. Remember to bend your knees, maintain a straight back, and utilize your legs to lift the pipes. If a pipe is too heavy to lift on your own, seek assistance or employ mechanical lifting equipment. 3. Secure Working Area: Ensure that the work area is tidy, well-organized, and devoid of tripping hazards. Keep the floor clear of tools, debris, and other obstructions that may lead to accidents. Additionally, establish barricades or cordons to prevent unauthorized access and guarantee the safety of others. 4. Use Proper Tools and Equipment: Employ the correct tools and equipment for the task at hand. This entails utilizing wrenches, pipe cutters, and clamps specifically designed for steel pipes. The usage of inappropriate tools can result in accidents, damage to the pipes, or faulty connections. 5. Proper Storage: Store steel pipes in a secure and organized manner to prevent them from falling or rolling onto individuals. Stack the pipes in a stable position and employ racks or supports to ensure they are not at risk of toppling over. 6. Secure Connections: When connecting steel pipes, ensure that the connections are adequately secured. This entails utilizing suitable fittings, tight fasteners, and adhering to the recommended torque specifications. Loose or improperly secured connections can lead to leaks, bursts, or other failures. 7. Proper Ventilation: If working in an enclosed space, ensure there is sufficient ventilation to prevent the accumulation of harmful gases or fumes. Welding or cutting steel pipes can release hazardous gases, so it is vital to ensure proper ventilation or employ respiratory protection if necessary. 8. Fire Safety: During welding or cutting processes, steel pipes can become extremely hot. Make sure to have fire extinguishers readily available and familiarize yourself with their usage. Remove any flammable materials from the work area and exercise caution around sparks or open flames. 9. Regular Inspections: Routinely inspect steel pipes for any signs of damage, such as cracks, rust, or degradation. Replace any damaged or compromised pipes to avoid potential failures or accidents. By adhering to these safety precautions, you can mitigate the risks associated with working with steel pipes and maintain a safe working environment. Always remember that safety should be the utmost priority.

1. Manufacturer Overview

| Location | Cangzhou,China |

| Year Established | 2010 |

| Annual Output Value | 200 million square meters |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | less than 10 |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 20,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords