Uline 1.5mil Reflective Adhesive Tape Colorful Cotton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product details

| Product | 3m reflective tape colorful cotton high quality |

| reflective coefficient | >400 CPL |

| total thickness | 400--500 micron |

| Color | yellow red silver gray |

| Backing fabric | cotton |

| Certification | ISO |

| Application | high flame retardant and heat resistance,ideal for working fields of fire protection,eletrical system |

| MOQ | 2600square meters |

2.Packaging & Delivery

Packaging Details:

standard carton packaging

Delivery Detail:

Shipped in 15 days after payment

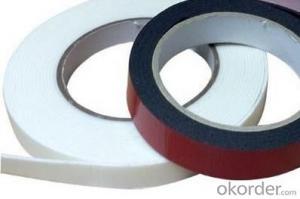

3.product show

4.About us

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

5.Factory and Certification

6.Our service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

7.FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. It provides a strong adhesive bond and helps keep the toy's packaging secure.

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, it is important to consider a few factors. Firstly, opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. This type of tape is less likely to cause damage or leave residue. Secondly, ensure that the surface is clean and free of any dirt or debris before applying the tape. This will help prevent any potential scratching or damage. Additionally, apply the tape gently and avoid excessive pressure or stretching, as this can cause the tape to adhere too strongly and potentially harm the delicate surface. Finally, when removing the tape, do so slowly and at a low angle to minimize the risk of tearing or leaving adhesive residue behind. By considering these factors, you can effectively use packaging tape on delicate surfaces while minimizing the risk of damage.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Indeed, plastic pet carriers can be effectively sealed using packaging tape. This tape is specifically created to securely seal packages and boxes, offering a powerful adhesive bond. With proper application, it can successfully seal the entrances of plastic pet carriers, guaranteeing the safety of your beloved pet. Nevertheless, it is crucial to ensure an even and secure application of the tape to avoid any potential gaps or openings through which your pet could escape. Furthermore, it is advisable to periodically inspect the tape's integrity and reapply it if needed.

- Q: Can packaging tape be used for sealing glass jars?

- Yes, packaging tape can be used for sealing glass jars. However, it is important to note that packaging tape is not specifically designed for sealing glass jars, and there are better alternatives available. While packaging tape may provide a temporary seal, it may not be as effective in maintaining the freshness and airtightness of the contents inside the jar. Additionally, packaging tape may not adhere well to glass surfaces and may peel off over time, potentially compromising the seal. It is recommended to use specialized jar sealing methods and materials such as rubber gaskets, metal lids with screw caps, or heat-sealing techniques for optimal results in preserving the contents of glass jars.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths for different applications. Packaging tape is available in various widths ranging from as small as 0.75 inches to as wide as 3 inches or even more. The choice of width depends on the specific application and the size of the package being sealed. Smaller widths are often used for lighter weight packages or for sealing small boxes or envelopes. On the other hand, wider widths are commonly used for heavy-duty or larger boxes that require extra strength and security. The availability of different widths allows users to select the most appropriate tape size based on their specific packaging needs.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. However, it is important to consider a few factors before using it. Firstly, ensure that the paint on the furniture is fully cured or dried, as using tape on fresh paint may cause it to peel off. Additionally, check the type of paint used on the furniture, as some types may be more prone to damage or discoloration from adhesive tape. To be on the safe side, you can test the tape on a small inconspicuous area of the furniture first to see if any damage occurs. It is also recommended to remove the tape carefully and slowly to minimize the risk of any damage.

- Q: What are the benefits of using high-tack packaging tape?

- Using high-tack packaging tape offers several advantages. To begin with, its adhesive is much stronger than that of regular packaging tape, ensuring a firm attachment to any surface it is applied to. This guarantees a secure and reliable seal for packages, preventing any potential opening or damage during transit. Moreover, high-tack tape is specifically designed to withstand a variety of environmental conditions, including extreme temperatures, humidity, and moisture. This makes it ideal for packaging items that may come into contact with harsh conditions during shipping or storage. The tape remains intact and maintains its adhesion, thus ensuring the package remains sealed and protected. Furthermore, high-tack packaging tape is often thicker and more durable than regular tape, providing increased strength and resistance against tearing or puncturing. This added durability is especially beneficial when shipping heavy or bulky items that require a stronger tape to hold them securely. In addition to its durability, high-tack tape is typically easy to use and dispense, making the packaging process more efficient. It is commonly available with a dispenser or in user-friendly formats such as rolls or strips, reducing the time and effort required to seal packages. Lastly, high-tack packaging tape can enhance the professional appearance of packages. It is often transparent or clear, allowing any logos or labels on the package to remain visible. This is particularly advantageous for businesses that aim to showcase their branding or ensure that important information is easily readable. In conclusion, the usage of high-tack packaging tape offers benefits such as superior adhesion, resistance to environmental conditions, durability, ease of use, and a professional appearance. These advantages make it the ideal choice for securing packages and ensuring their safe and secure delivery.

- Q: Is packaging tape safe to use on delicate items?

- Yes, packaging tape can be safe to use on delicate items as long as it is applied with caution and does not directly touch or damage the delicate surface. It is recommended to use a gentle and removable adhesive tape specifically designed for delicate items to ensure their safety during packaging.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Yes, packaging tape is generally easy to remove without damaging surfaces. It is designed to adhere securely to packages, but also to be easily peeled off without leaving residue or causing damage to most surfaces.

- Q: What are the benefits of using easy-release packaging tape?

- The benefits of using easy-release packaging tape are numerous and can greatly simplify the packaging process. Firstly, easy-release packaging tape is designed to have a low adhesion level, which means it can be easily removed without leaving any residue or damaging the surface it was applied to. This is particularly useful when packaging delicate or valuable items, as it ensures that the tape can be removed without causing any damage. Furthermore, easy-release packaging tape is also time-saving. It can be quickly applied and removed, which increases efficiency and saves valuable time for individuals or businesses that frequently package and ship items. The ease of use also reduces the chances of mishaps or errors during the packaging process, resulting in a smoother and more streamlined experience. Additionally, the ease of release offered by this type of tape makes it more environmentally friendly. Since it can be easily removed without leaving any sticky residue, it reduces the need for excessive cleaning or scraping, which can be time-consuming and may require the use of harmful chemicals. This not only benefits the environment but also reduces costs associated with cleaning supplies and labor. Lastly, easy-release packaging tape offers versatility. It can be used for a wide range of applications, including sealing boxes, securing packages, or bundling items together. The tape is often available in different sizes and materials, allowing users to choose the most suitable option for their specific needs. Overall, the benefits of using easy-release packaging tape include easy removal without residue or damage, time-saving properties, environmental friendliness, and versatility. These advantages make it an excellent choice for anyone looking to simplify their packaging process and ensure a hassle-free experience.

Send your message to us

Uline 1.5mil Reflective Adhesive Tape Colorful Cotton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords