3M Colored Packaging Tape - Double Sided Antistatic Tissue Adhesive Multiple Use Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

Desc | Double Sided Antistatic Tissue Adhesive Multiple Use Tape | |

Item No. | DT-22 | |

18G/Backing | 18g tissue | |

Thickness | 120mic | 140mic |

Tack | ≥20# | ≥24# |

180° Peeling | ≥16N/25mm | ≥20N/25mm |

Holding power | ≥8hrs | |

Temperature resistance | 60℃ | |

Color | Clear/Yellow | |

Usage | Embroidery | |

2.Packaging & Delivery

Packaging Details:

Polybag package or customized package

Jumbo roll: max length: 800m

Max width: 1260mm (usable 1240mm); 1040mm (usable 1020mm)

Slit roll: width/length available upon request

Delivery Detail: 10-25 working days after deposite receiptDelivery Detail:

Shipped in 15-25 working days after payment

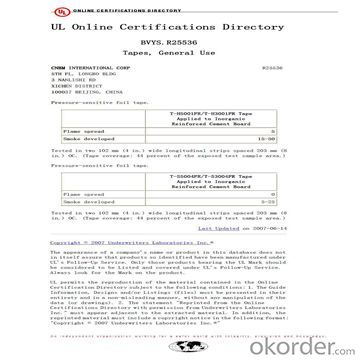

3.Certification and Factory

4.Product show:

5.Our service:

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

6.FAQ:

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: How do I prevent packaging tape from curling up?

- To prevent packaging tape from curling up, there are a few things you can try: 1. Ensure the surface is clean and dry before applying the tape. Any moisture or debris can affect the adhesive and cause curling. 2. Use a tape dispenser or a tape gun for a more controlled application. This helps in keeping the tape straight and prevents it from curling. 3. Pull the tape tightly as you apply it to the surface. A snug and even application helps in preventing curling. 4. Avoid stretching the tape excessively, as this can weaken the adhesive and cause curling. 5. Store your tape in a cool, dry place to maintain its adhesive properties. Extreme temperatures or high humidity can impact the tape's performance. 6. If the tape still curls despite these measures, consider using a different type or brand of packaging tape that is known for its anti-curling properties.

- Q: Does packaging tape come in different eco-friendly options?

- Yes, packaging tape is available in different eco-friendly options. Many companies now offer packaging tape made from recycled and biodegradable materials, such as paper or plant-based adhesives. These eco-friendly alternatives help reduce the environmental impact of packaging materials.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When working with plastic packaging materials and using packaging tape, it is essential to keep several important factors in mind. These factors include: 1. Adhesive Compatibility: Ensuring that the adhesive used in the packaging tape is compatible with the specific type of plastic material is crucial. Different plastics have different surface properties, and they may require different adhesive formulations to ensure proper bonding. For instance, low surface energy plastics like polyethylene may necessitate a tape with a specially designed adhesive for such surfaces. 2. Strength and Durability: Plastic packaging materials come in varying thicknesses and strengths. When choosing packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, thus maintaining the package's integrity during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures, such as heat or cold, the packaging tape should be capable of withstanding these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can impact the tape's adhesion. Therefore, it is important to select a tape suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can pose a problem if the packaging needs to be reused or if the plastic material is susceptible to damage. By choosing a packaging tape that is designed to be easily removable or leaves minimal residue, these concerns can be mitigated. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that must be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By taking these factors into consideration, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q: Does packaging tape leave residue?

- Indeed, surfaces can be affected by residue when packaging tape is used. This occurrence arises from the fact that the majority of packaging tapes possess adhesive properties, meant to firmly adhere to surfaces. Consequently, when the tape is detached, it has the potential to leave a sticky residue behind which may prove arduous to eliminate. Moreover, this residue is prone to accumulating dust and dirt, thereby intensifying the difficulty of the cleaning process. Nonetheless, there are certain packaging tapes available that are explicitly engineered to minimize or entirely eliminate residue upon removal. To guarantee the absence of any unwanted residue, it is always prudent to conduct a preliminary test on a small area of delicate or valuable surfaces before employing packaging tape.

- Q: Is packaging tape resistant to punctures or tears?

- Packaging tape, in general, exhibits resistance to punctures or tears. Its purpose is to possess strength and durability, specifically for the task of securing and sealing packages. Packaging tape derives its composition from materials like polypropylene or polyester, which possess high tensile strength and provide exceptional resistance against punctures or tears. Moreover, packaging tape commonly possesses adhesive properties that further augment its capacity to withstand punctures or tears. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate based on the particular type and quality of packaging tape employed.

- Q: What are the different types of packaging tape available?

- There is a wide range of packaging tape options to choose from, each tailor-made for specific purposes and applications. Here are a few commonly used varieties: 1. Transparent packaging tape: This is the most commonly employed type of packaging tape due to its versatility. It is transparent and boasts a strong adhesive bond, making it ideal for sealing boxes and packages. 2. Brown packaging tape: Also referred to as "brown tape" or "packing tape," this tape is typically constructed from brown or tan-colored material and reinforced with fiberglass. It offers exceptional strength and durability for securing heavy or bulky packages. 3. Masking tape: Although not specifically designed for packaging, masking tape can be used for light-duty sealing or labeling needs. It is easily removable and leaves no residue, making it suitable for temporary applications. 4. Duct tape: Renowned for its strength and versatility, duct tape is not primarily intended for packaging purposes but can be utilized in certain situations. It possesses a powerful adhesive bond and is known for its ability to stick to various surfaces, including uneven or rough ones. 5. Filament tape: This tape is fortified with fiberglass filaments, providing incredible strength and resistance. Filament tape is commonly used for bundling or reinforcing heavy or irregularly shaped items. 6. Double-sided tape: Unlike other packaging tapes, double-sided tape has adhesive on both sides and is employed for a variety of applications, such as bonding two surfaces together or mounting objects. 7. Kraft paper tape: Crafted from a renewable resource, kraft paper tape serves as an eco-friendly alternative to plastic tapes. It requires moistening before application as it is water-activated. Kraft paper tape delivers a robust seal and is often utilized for sealing cartons or packages that contain valuable or fragile items. 8. Colored packaging tape: This tape comes in a range of colors and is commonly used for color-coding packages, labeling, or enhancing the aesthetic appeal of packages. These represent just a few of the packaging tape options available in the market. Each type possesses its own distinct characteristics and is suitable for specific packaging requirements. When selecting the appropriate tape, it is crucial to consider factors such as the weight and nature of the package, the environment it will be exposed to, and any specific regulations or requirements that may be applicable.

- Q: Can packaging tape be used on different surfaces, such as cardboard, plastic, or metal?

- Yes, packaging tape can be used on different surfaces such as cardboard, plastic, or metal. Packaging tape is designed to provide a strong and secure seal, making it suitable for various materials. It adheres well to the rough surface of cardboard, ensuring that boxes and packages remain securely sealed during transit. Additionally, packaging tape can adhere to smooth surfaces like plastic, ensuring that items are securely packaged and protected. It can also be used on metal surfaces, providing a reliable seal for packages and boxes made of metal. Overall, packaging tape is versatile and can be used on different surfaces, making it an essential tool for packaging and shipping needs.

- Q: What are the benefits of using reinforced packaging tape?

- Reinforced packaging tape offers numerous advantages. To begin with, it is specifically designed to provide greater strength and durability compared to regular tape. By incorporating a layer of robust fiberglass or nylon threads into the tape, it significantly enhances its resistance to tearing and breaking. This added strength makes it perfect for securely sealing heavy or bulky packages, guaranteeing their integrity during transportation or storage. Furthermore, reinforced packaging tape adds an extra layer of security to your shipments. The presence of reinforced fibers within the tape makes it much more challenging to tamper with or remove without detection. This serves as a deterrent against theft or unauthorized access, ensuring that your packages reach their destination safely and intact. Moreover, reinforced packaging tape boasts exceptional adhesive properties. It securely adheres to various surfaces, including cardboard, plastic, and other commonly used packaging materials. This strong adhesion ensures that the tape remains firmly in place and does not easily peel off, even under demanding conditions like extreme temperatures or rough handling during shipping. Additionally, reinforced packaging tape often possesses water-resistant or even waterproof qualities. This is particularly crucial when packages are exposed to moisture or unfavorable weather conditions. The tape's resistance to water helps shield the contents of your packages from potential damage caused by water or humidity. Lastly, the utilization of reinforced packaging tape can lead to cost savings and waste reduction. Its exceptional strength and durability allow you to use less tape to secure your packages, resulting in fewer tape rolls being used and less waste generated. Over time, this can lead to substantial cost savings and contribute to a more sustainable packaging process. In conclusion, the utilization of reinforced packaging tape offers a range of benefits, including increased strength, enhanced security, strong adhesion, water resistance, and potential cost savings. By investing in high-quality reinforced tape, you can ensure the reliable protection of your packages during transit, providing both you and your customers with peace of mind.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. Packaging tape is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it's important to consider the type of plastic hanger you have and the purpose for which it is being used. While packaging tape may work well for temporarily holding clothes on a plastic hanger, it may leave residue or cause damage if left for an extended period. It's advisable to test a small area of the hanger first to ensure that the tape does not cause any harm or leave any marks. Additionally, if the plastic hanger is being used for displaying or storing delicate or valuable clothing, it may be better to opt for gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

Send your message to us

3M Colored Packaging Tape - Double Sided Antistatic Tissue Adhesive Multiple Use Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords