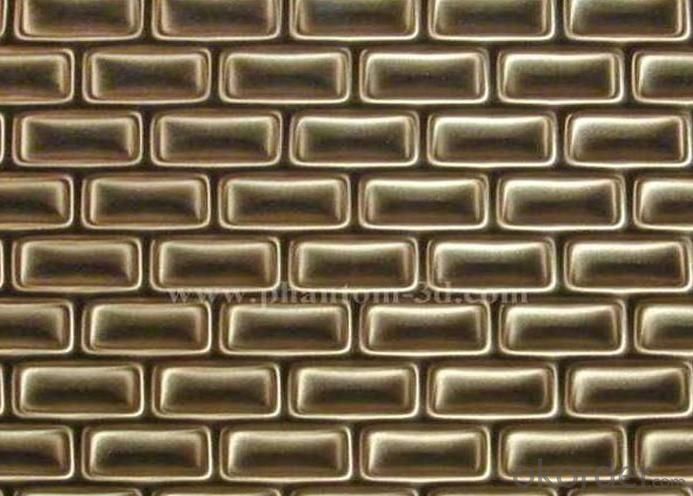

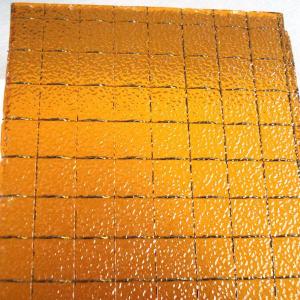

3D Float Glass/Decorative Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Square Meters m²

- Supply Capability:

- 12000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of 3D Float Glass, Decorative Glass

Max Size:1830*2440mm

Standard Size:300*300mm,600*600mm, thickness:5mm,6mm,8mm,10mm

Raw material: float glass (car grade), can be tempered.

Standard size: 1.83m(W) x 2.44m(L) x 5mm(thickness), 300mm x 300mm, 300mm x 600mm, 600mm x 600mm, can be made to order.8mm,10mm,12mm and 15mm thick are available.

Pattern: 22 series, cloth, volcano, vertical, barcode, rock, etc.(More patterns will be designed)

Color: 14 colors, purple, black, gold, China red, blue, etc.(more colors are expected)

Performance: It's a kind of environment friendly item which is processed by surface technology and appears stereoscopic and vivid optic effects, it can substitute or match with ceramic tile, stone, mirror, wallpaper for interior decoration, the panel can be cut into desired size or shapes, also you can choose standard tiles for DIY matching.

Application of 3D Float Glass, Decorative Glass

a. public decoration: hotel, KTV, bar, club, restaurant, office, etc.

b. home decoration: living room, bed room, bath room, kitchen, etc.

c. used on wardrobe, cabinet, etc.

Delivery time: 15-20 days

Packing: packed in wooden case, every pc of glass is protected by PE foam film.

- Q: What is the raw material of glass products?

- It's quartz sand (that is sand). The chemical name is SiO2

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass fiber reinforced plastic used for raw materials, resin, glass fiber reinforced plastic fiber silk, filler, calcium powder to 1:1:1 ratio configuration, high-quality glass fiber reinforced plastic choose high-quality resin: unsaturated ortho benzene resin 196, colorless transparent. Low viscosity, low heat release, low shrinkage, high speed cure, high speed compatibility and gloss.

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- At present, there are three kinds of insulating glass in China: (1) groove aluminum type single channel sealing; (two) groove aluminum double channel sealing; (three) compound sealant strip type insulating glass.

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main constituents of the glass are calcium silicate, sodium silicate and silicaExpensive and not expensive must be related to quality (at least with impurities)

- Q: What is the raw material of glass? How is it converted to glass?

- Formed by converting molten glass to a solid product of a fixed shape. The process must take place within a certain temperature range. This is a cooling process. The glass is first converted from a viscous liquid to a plastic state, and then to a brittle solid. The forming method can be divided into two categories: manual forming and mechanical forming.

- Q: How is glass made, raw material proportioning?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

- Q: Is glass fiber reinforced metal material?

- The advantages include soft and hard, corrosion resistance, aging resistance, waterproof and insulation, high mechanical strength, recycling, can replace steel manufacturing machine parts, it is used in manufacturing a variety of sports equipment, shell pipeline, shipbuilding, automobile and electronic products and printed circuit board.

- Q: What is quartz made of?

- 7, electronic high purity silicon metal, optical fiber 8, rubber and plastic filler (which can improve the wear resistance of 9), paint filler (which can improve the weatherability of coatings) 10, aerospace and aviation, the internal structure of molecular chain, crystal shape and lattice changes, make its temperature resistance, coefficient of thermal expansion small, high insulation, corrosion resistance, piezoelectric effect, resonance and its unique optical properties.

- Q: As the raw material for glass wool is what

- According to the manufacturing process of products and the use of different glass cotton products will be divided into eight categories, are described as follows.1, glass wool cement products2, glass cotton textile products3, glass wool insulation products4, glass cotton rubber products5, glass cotton brake (drive) products6, glass cotton electrical materials7, glass cotton asphalt products8, the new use of color glass wool and glass wool cement products

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- B grade crystal beads: flat emery discs are cut one by one, and polished by batch machines with a polishing machine!

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2002 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | shen zhen,guang zhou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

3D Float Glass/Decorative Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Square Meters m²

- Supply Capability:

- 12000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords