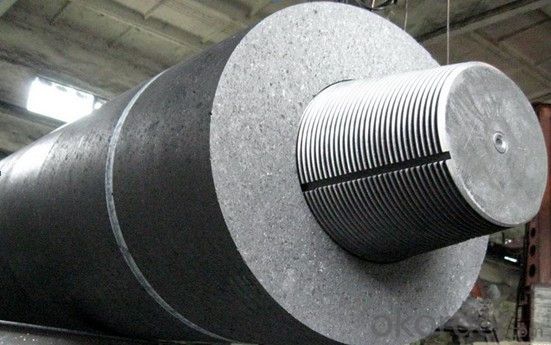

350*1800mm High Quality 200mm Graphite Electrode Factory Direct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

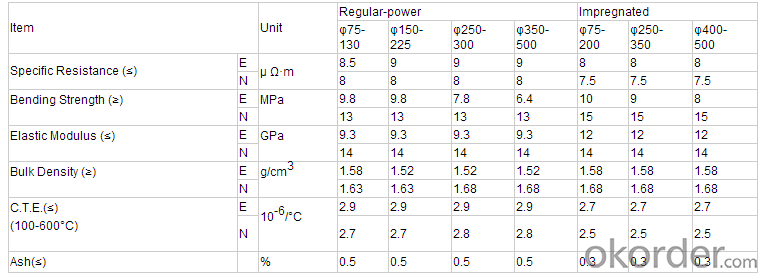

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why should supercapacitors use graphite as electrode material?

- Because the graphite material's electrochemical stability is good, can let the super capacitor withstand the higher monomer voltage. The electrode is not easy to wear out.

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The power supply adopts the DC arc welding machine with steep drop characteristic, adopts the positive connection method, the electrode is negative, and the electrode is a high strength spectrum pure graphite rod,

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: What's the use of carbon?

- High power graphite electrode. Allows the use of current density of 18 ~ 25A/ cm 2 graphite electrode, mainly used in steel-making high power arc furnace

- Q: Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- The oxygen will react with the graphite and the gas will dissolve.The iron has been oxidized.

- Q: Can Naiduo high temperature graphite

- Graphite gasket medium: hot water, steam, oil, acid, alkali, ammonia, hydrogen, organic solvents, hydrocarbons, cryogenic liquids, etc..Maximum use pressure of graphite gasket: 30MPa.Service temperature of graphite gasket: -200~650

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- So that impurities on the high, so basically can not be processed into so-called quality, and can leave a contact, discuss each other

- Q: Graphite electrode press device

- High power graphite electrodes. Graphite electrodes with a current density of 18 ~ 25A / cm 2 are allowed. They are mainly used in high power arc furnaces for steelmaking

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

- Q: What are pyrolytic graphite electrodes used for?

- In 1960s, copper is widely used as electrode material, usage rate of about 90%, about graphite only 10%; in twenty-first Century, more and more users start using graphite as the electrode material, in Europe, more than 90% above the graphite electrode material is. Copper, the once dominant electrode material, has almost lost its advantages over graphite electrodes.

Send your message to us

350*1800mm High Quality 200mm Graphite Electrode Factory Direct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords