316L Stainless Steel Channels-SKY

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

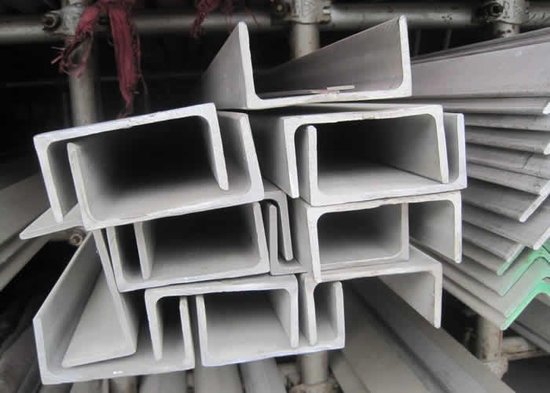

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q: Are stainless steel channels resistant to bacterial or fungal growth?

- Stainless steel channels possess high resistance against the growth of bacteria or fungi. This is due to the fact that stainless steel is renowned for its non-porous and smooth surface, which creates an unfavorable environment for bacteria or fungi to adhere and thrive. Furthermore, stainless steel possesses inherent properties that hinder the growth of microorganisms, making it an ideal choice for applications where cleanliness is of utmost importance, such as in the food and pharmaceutical industries. The robustness and corrosion resistance of stainless steel also contribute to its ability to withstand harsh cleaning agents and disinfectants, thus further minimizing the risk of bacterial or fungal contamination. All in all, stainless steel channels are an exceptional option when it comes to preventing the growth and propagation of bacteria or fungi.

- Q: Are stainless steel channels fire-resistant?

- Indeed, stainless steel channels possess fire-resistant properties. Owing to its elevated melting point and minimal thermal conductivity, stainless steel is considered a material with exceptional fire resistance. It retains its structural integrity even when subjected to exceedingly high temperatures. Consequently, stainless steel channels are a dependable option for circumstances where fire resistance is of utmost importance, such as in the establishment of fire-rated walls, ceilings, and other fire containment systems. Moreover, stainless steel does not emit toxic gases or produce smoke when exposed to fire, thereby augmenting its fire-resistant characteristics.

- Q: Can stainless steel channels be used for airport or transportation infrastructure?

- Indeed, airport and transportation infrastructure can indeed make use of stainless steel channels. The reason behind this is that stainless steel possesses remarkable attributes such as durability, strength, and resistance to corrosion, which make it an ideal option for withstanding harsh environments like airports and transportation infrastructure. Stainless steel channels offer a versatile solution that can serve various purposes, including providing support structures, handrails, cable management, and drainage systems. With their capacity to endure heavy loads and exposure to diverse weather conditions, stainless steel channels guarantee a solid and long-lasting outcome. Moreover, their aesthetically pleasing appearance and low maintenance requirements make them a highly practical choice for airport and transportation infrastructure projects.

- Q: Can stainless steel channels be used in rooftop installations?

- Yes, stainless steel channels can be used in rooftop installations. Stainless steel is highly resistant to corrosion and is known for its durability, making it suitable for outdoor applications. It can withstand harsh weather conditions, including exposure to rain, sun, and temperature fluctuations, making it an ideal choice for rooftop installations. Additionally, stainless steel channels provide structural support and can be used to secure various rooftop equipment such as solar panels, HVAC units, and satellite dishes, among others.

- Q: Can stainless steel channels be used in the oil and gas industry?

- Yes, stainless steel channels can be used in the oil and gas industry. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it a suitable material for various applications in this industry. Stainless steel channels are often used for structural support, as well as for constructing platforms, walkways, and other infrastructure in oil and gas facilities. Additionally, stainless steel channels can withstand high temperatures and pressures, making them suitable for use in pipelines, tanks, and equipment used in the extraction, refining, and transportation of oil and gas.

- Q: How do stainless steel channels contribute to building codes and regulations?

- Stainless steel channels contribute to building codes and regulations by providing structural support and reinforcement in various building applications. These channels are manufactured to meet specific standards and requirements outlined by building codes, ensuring their strength, durability, and reliability. By incorporating stainless steel channels into construction projects, builders and designers can comply with safety regulations, enhance structural integrity, and ensure the longevity of the building.

- Q: What are the design considerations when using stainless steel channels?

- When using stainless steel channels, some important design considerations include the material's corrosion resistance, strength and durability, dimensional stability, and aesthetic appeal. Additionally, factors like load-bearing capacity, compatibility with other materials, and ease of installation may also need to be taken into account.

- Q: Do stainless steel channels have a high strength-to-weight ratio?

- Yes, stainless steel channels have a high strength-to-weight ratio. This is due to the inherent strength of stainless steel as a material and its relatively low density. Stainless steel is known for its excellent mechanical properties, including high tensile strength and durability. These properties allow stainless steel channels to withstand heavy loads and resist deformation under stress, while still being lightweight in comparison to other materials with similar strength. As a result, stainless steel channels are widely used in various industries where high strength and structural integrity are essential requirements.

- Q: How does stainless steel compare to other materials when it comes to channel construction?

- Stainless steel is often considered the superior choice when it comes to channel construction compared to other materials. One of the main advantages of stainless steel is its exceptional corrosion resistance. It has a natural ability to withstand exposure to various environmental elements such as moisture, chemicals, and high temperatures, making it highly durable and long-lasting. Additionally, stainless steel has high strength and excellent structural integrity, making it suitable for heavy-duty applications. It can withstand significant loads and stresses without deformation or failure, ensuring the stability and reliability of the channel construction. Another key benefit of stainless steel in channel construction is its aesthetic appeal. It has a sleek and modern appearance that can enhance the overall visual appeal of the structure. This makes it a popular choice for both functional and decorative purposes. Furthermore, stainless steel is highly versatile and can be easily customized to meet specific project requirements. It can be fabricated into various shapes and sizes, allowing for flexibility in design and construction. Whether it is for drainage systems, cable management, or water channels, stainless steel can be tailored to fit the specific needs of the application. In comparison to other materials like concrete or plastic, stainless steel offers numerous advantages. Concrete can be prone to cracking and degradation over time, while plastic channels may not have the same level of strength and durability as stainless steel. Overall, stainless steel provides a combination of strength, corrosion resistance, aesthetic appeal, and versatility that makes it a superior choice for channel construction when compared to other materials.

- Q: How do stainless steel channels compare to galvanized channels?

- Stainless steel channels and galvanized channels are both popular choices in construction and industrial applications, but they have some key differences. One major difference is their corrosion resistance. Stainless steel channels are highly resistant to corrosion, thanks to the presence of chromium in their composition. This makes them suitable for use in environments where they will be exposed to moisture, chemicals, or other corrosive substances. Galvanized channels, on the other hand, are coated with a layer of zinc to protect them from corrosion. While this zinc coating provides some level of protection, it can wear off over time, leaving the underlying steel vulnerable to rust and corrosion. Another difference is their strength and durability. Stainless steel channels are known for their high strength and durability, making them suitable for applications that require heavy loads or structural support. Galvanized channels, while still strong, may not be as robust as stainless steel channels. They may be more prone to bending or warping under heavy loads or extreme conditions. Cost is another factor to consider. Galvanized channels are generally more affordable than stainless steel channels, making them a cost-effective option for many projects. However, the initial cost savings of galvanized channels may be overshadowed by the need for regular maintenance or replacement due to corrosion. Stainless steel channels, while more expensive upfront, require minimal maintenance and have a longer lifespan, making them a more economical choice in the long run. In summary, stainless steel channels offer superior corrosion resistance, strength, and durability compared to galvanized channels. While galvanized channels may be more cost-effective initially, the potential for corrosion and the need for maintenance or replacement may outweigh the initial savings. Ultimately, the choice between stainless steel channels and galvanized channels depends on the specific requirements of the project and the level of corrosion resistance and durability needed.

Send your message to us

316L Stainless Steel Channels-SKY

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords