3105 Aluminum Coil for Coated Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Coated Aluminum Coil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Coated Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Coated Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

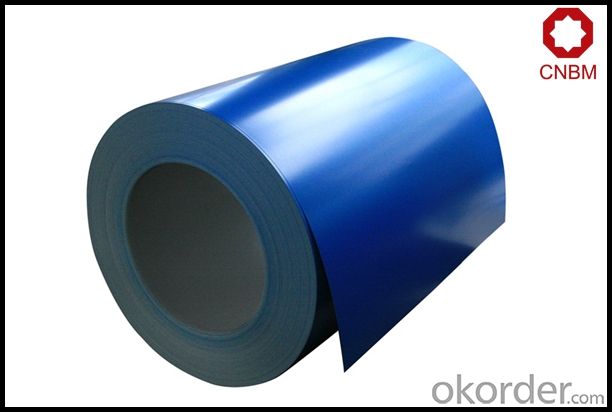

5. Image of Coated Aluminum Coil

6. Package and shipping of Coated Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be customized?

- Yes, aluminum coils can be customized. They can be manufactured in various sizes, thicknesses, and shapes to meet specific requirements and applications. Additionally, they can undergo surface treatments, such as coatings or finishes, to enhance corrosion resistance or aesthetic appearance.

- Q: This question asks for a comparison between cold rolling and hot rolling processes, specifically in the context of steel wire production for coilings.

- <p>Cold rolling and hot rolling are two distinct processes used in the manufacturing of steel wires for coilings. Hot rolling is performed at high temperatures, typically above the recrystallization temperature of the steel, which allows the material to be shaped more easily. This process results in a more ductile and less hard steel, which can be beneficial for certain applications. However, hot-rolled steel may have a rougher surface and may require further processing to achieve desired dimensions and surface finish. Cold rolling, on the other hand, is done at room temperature, which imparts a harder and smoother surface to the steel. It is more precise and results in tighter tolerances, making it suitable for applications requiring high strength and precision. Cold-rolled steel also has better surface finish and dimensional accuracy compared to hot-rolled steel. However, cold rolling is more energy-intensive and may not be suitable for very thick materials due to the increased hardness of the steel at room temperature.</p>

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: Can aluminum coils be utilized to create jewelry boxes and other decorative objects?

- <p>Yes, aluminum coils can be used to make jewelry boxes and other decorative items. Aluminum is lightweight, durable, and has a shiny finish that can add a touch of elegance to decorative pieces. It can be easily shaped and manipulated using various tools and techniques, such as bending, cutting, and engraving. Additionally, aluminum's resistance to corrosion makes it a practical choice for long-lasting decorative items. However, it's important to consider that working with aluminum may require specific skills and tools, and the final appearance can be influenced by the quality of the aluminum and the craftsmanship involved.</p>

- Q: Are aluminum coils suitable for interior decorative applications?

- Indeed, interior decorative applications are well-suited for aluminum coils. This material, being lightweight and flexible, lends itself to effortless shaping into diverse forms, thus making it perfect for decorative purposes. Moreover, aluminum offers a vast array of finishes, colors, and patterns, granting limitless design options. In addition, its remarkable durability and corrosion resistance guarantee its enduring aesthetic appeal. Furthermore, aluminum is an environmentally friendly choice, as it can be recycled indefinitely, making it a sustainable material for interior decorations. All in all, aluminum coils offer a cost-effective and visually appealing alternative for interior decorative applications.

- Q: Can aluminum coils be customized according to specific requirements?

- Yes, aluminum coils can be customized according to specific requirements. Aluminum coils can be tailored to meet specific dimensions, thicknesses, and finishes to suit various applications. Customization options can include specific alloys, tempering processes, and even specialized coatings to enhance corrosion resistance or improve appearance. Additionally, aluminum coils can be fabricated with specific features such as perforations, embossing, or edge treatments to meet specific functional or aesthetic requirements. With the ability to be customized, aluminum coils offer flexibility and versatility for a wide range of industries and applications.

- Q: How do aluminum coils contribute to LEED certification requirements?

- Aluminum coils can contribute to LEED (Leadership in Energy and Environmental Design) certification requirements in several ways. First, aluminum is a highly sustainable material as it is 100% recyclable without any loss of quality. This means that using aluminum coils in construction projects can contribute to LEED credits for materials and resources, specifically in the category of recycled content. Additionally, aluminum coils are known for their energy efficiency properties. Aluminum is a lightweight material, which means less energy is required for transportation and installation compared to heavier alternatives. Furthermore, aluminum coils have excellent thermal conductivity, allowing for efficient heat transfer and reducing the energy consumption required for heating and cooling systems. These energy-saving benefits can contribute to LEED credits in the categories of energy and atmosphere. Moreover, aluminum coils have a long lifespan and require minimal maintenance. This durability reduces the need for frequent replacements and decreases waste generation. LEED recognizes the use of durable materials that promote longevity and reduce the environmental impact caused by constant replacements. Therefore, incorporating aluminum coils into a construction project can help earn LEED credits for sustainable sites and materials and resources. In conclusion, aluminum coils contribute to LEED certification requirements by offering high levels of recyclability, energy efficiency, and durability. Utilizing aluminum coils in construction projects can help achieve LEED credits in various categories, ultimately promoting sustainable and environmentally-friendly building practices.

- Q: This question asks for a comparison between aluminum coils and other metal coils, highlighting their distinct characteristics.

- <p>Aluminum coil is distinct from other metal coils due to its lightweight, high corrosion resistance, and excellent thermal and electrical conductivity. Compared to steel coils, aluminum coils are softer and more ductile, making them easier to bend and shape without breaking. They are also non-magnetic and have a lower melting point. Copper coils, on the other hand, have superior electrical conductivity but are heavier and more expensive. Zinc coils offer good corrosion resistance but are less ductile and have lower strength. Each metal coil has specific properties that make them suitable for different applications, such as construction, electrical wiring, or automotive parts.</p>

- Q: I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- Plaster releases water at two points - in ordinary or accelerated drying it loses the water needed for setting and stops feeling cool and feels dry. If it is heated past 900F it loses chemically bound water and may fall apart. Aluminum melts at several hundred degrees higher than this and if the mold is intended to hold a mass of aluminum is is likely to destroy the mold. If the aluminum casting is fairly flat less of a problem. The common method for dealing with this is to add 50% silica flour (bad for lungs warning) to the dry plaster when making the mold. Then the mixed material mold can be used and preheated to take materials at least up to fused/molten glass, although the mold is commonly lost (not reusable) at these temps and just barely holds together.

- Q: How are aluminum coils processed for specific surface coatings?

- To achieve specific surface coatings on aluminum coils, a series of steps are undertaken. These steps encompass cleaning, pre-treatment, coating application, and curing. Initially, the aluminum coils are subjected to a thorough cleaning process to eliminate any dirt, grease, or contaminants that may impede the coating's adhesion. This typically involves utilizing chemical cleaning agents, rinsing, and sometimes mechanical techniques. Following the cleaning stage, the coils undergo a pre-treatment process, which readies the aluminum surface for optimal coating adhesion. Depending on the specific coating requirements, this pre-treatment may involve chemical etching, conversion coating, or a combination of both. Chemical etching creates a rough surface that enhances the bond between the aluminum and the coating, while conversion coating forms a thin layer that enhances corrosion resistance and adhesion. Upon completion of the pre-treatment, the desired surface coating is applied to the aluminum coils. This can be accomplished using various methods such as coil coating, spray coating, or electrostatic coating. Coil coating is a prevalent technique in which the coil is continuously fed through a coating line, ensuring the even and precise application of the coating material onto the surface. Following the coating application, the aluminum coils undergo a curing process to ensure proper adhesion and hardening of the coating. Curing can be achieved through heat, whereby the coated coils are passed through an oven or furnace at a specific temperature and duration to facilitate cross-linking and curing of the coating material. Alternatively, certain coatings may necessitate UV curing, wherein the coated coils are exposed to ultraviolet light to achieve the desired curing process. In summary, the process of processing aluminum coils for specific surface coatings involves cleaning, pre-treatment, coating application, and curing. This comprehensive approach guarantees that the coils are adequately prepared and coated to meet the desired surface properties and performance requirements.

Send your message to us

3105 Aluminum Coil for Coated Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords