3/4 Plywood 4x8 Sheets for Container Flooring Maintenance Use

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Plywood for Container Flooring Maintenance Use

General Information of Container Plywood Flooring

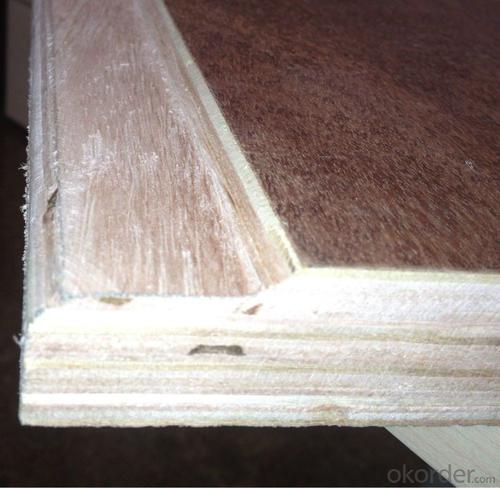

The floor of container usually consists of marine hardwood plywood made from Apitong or Keruing in 25-30mm thickness.

It is occasionally varnished but with costs being kept to a minimum these days it will usually come in a plain finish and treated.

Specifications of Container Plywood Flooring

1)Size: 1160×2400mm, 1220×2440mm, as request

2)Thickness: 28mm (19 plys)

3)Face: birch, keruing, apitong , thickness from 0.5mm to 1.2mm. Core: full birch or full hard wood ;keruing

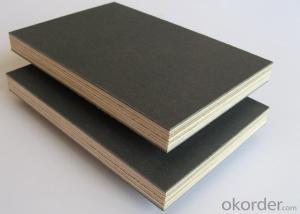

4)Glue: WBP phenolic

5)Density: 700kg/m3 or up

6)Glue bonding: not less than 0.7 Mpa

7)Mositure content: less than 12%

8)Surface treatment: lacquer coating or plain surface

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Plywood in the material defects?

- Abnormal structure Any defects caused by abnormal wood construction, such as wrinkles. Wavy pattern. Staggered pattern, spiral pattern and so on.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: Selection of plywood in plywood production

- In the production of plywood, derived from a lot of color varieties, one of the most important one is in the original plywood board surface affixed with a thin layer of decorative veneer, known as decorative veneer veneer plywood, the market referred to as decoration Board or trim panel.

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: Plywood can improve timber utilization and is a major way to save wood.

- side panels are made of pure solid wood, do not use any other form of wood-based panels

- Q: Contemporary plywood market development

- but also China's development of plywood industry cost accounting and other plywood production countries compared to the advantages of an important factor. China plywood product quality itself

- Q: What are the key points for plywood selection?

- According to the nature of the project, the use of parts, environmental conditions and other factors use different types, grades, materials, decoration and format plywood.

- Q: What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

- Q: What is medium density fiberboard

- The total thickness of the panel and back panel of the joinery board should be greater than 3 mm, and the panels allow proper patching.

Send your message to us

3/4 Plywood 4x8 Sheets for Container Flooring Maintenance Use

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords