2mm Stucco Embossed Aluminum Sheet Metal Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall doors...

(2).Exterior: wall ...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminium (or aluminum; see different endings) is a chemical element in the boron group with symbol Al andatomic number 13. It is a silvery-white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal, in the Earth's crust. It makes up about 8% by mass of the crust, though it is less common in the mantle below.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

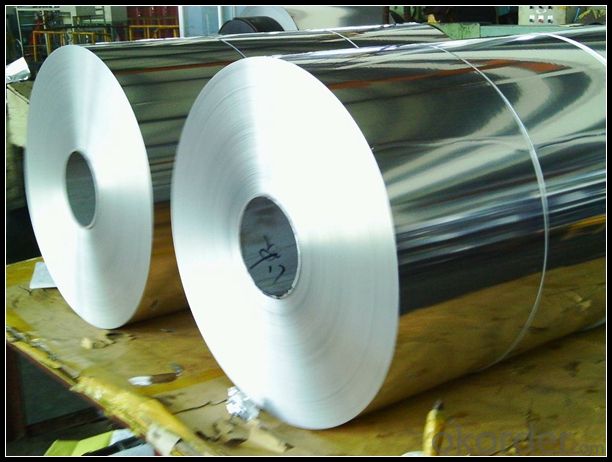

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What characteristics of aluminum strips make them ideal for specific uses?

- <p>Aluminum strips are suitable for certain applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. They are also known for their good thermal and electrical conductivity, making them ideal for heat sinks and electrical components. Additionally, aluminum strips are easily machinable and can be formed into various shapes, which is beneficial for manufacturing. Their non-magnetic properties are advantageous in applications where magnetic interference is a concern. Lastly, aluminum's recyclability and cost-effectiveness make it an environmentally friendly and economical choice for many industrial applications.</p>

- Q: Is it possible to utilize aluminum strips for creating decorative patterns or designs on the exterior of buildings?

- <p>Yes, aluminum strips can be used to create patterns or designs on building exteriors. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum strips can be cut, bent, and shaped into various forms to create intricate designs and patterns. They can also be anodized or painted to achieve different colors and finishes, enhancing the aesthetic appeal of the building's exterior.</p>

- Q: Is it possible to utilize aluminum strips in outdoor settings?

- <p>Yes, aluminum strips can be used for outdoor applications. They are known for their corrosion resistance, making them suitable for outdoor environments where they may be exposed to various weather conditions. Aluminum's durability and lightweight properties also make it a popular choice for outdoor construction and decoration. However, it's important to ensure that the aluminum is properly treated or coated to enhance its resistance to weathering and maintain its appearance over time.</p>

- Q: What other materials could potentially be used in place of aluminum strips for specific uses?

- <p>Yes, there are alternative materials that can replace aluminum strips in certain applications. These include stainless steel, which offers high strength and corrosion resistance; copper, known for its excellent electrical conductivity; magnesium alloys, which are lightweight and have good thermal conductivity; and titanium, prized for its strength and resistance to corrosion. The choice of material depends on the specific requirements of the application, such as strength, weight, cost, and environmental factors.</p>

- Q: What kind of mask is good for welding aluminum strips?

- However, the overall quality of the active carbon mask is not high, carbon content, filtration efficiency is not up to standard. You can choose some professional brands to produce some products, to avoid these problems.

- Q: What are the specific types of aluminum strips that are frequently utilized in the construction industry?

- <p>Yes, there are several special types of aluminum strips commonly used in construction. These include aluminum flashing strips for waterproofing and sealing, aluminum trim strips for finishing edges and corners, and aluminum heat sinks for heat dissipation in electrical installations. Additionally, aluminum strips are used in curtain wall systems, window frames, and as reinforcement in concrete structures. The choice of aluminum strip depends on the specific requirements of the construction project, such as strength, durability, and resistance to corrosion.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: What are the safety standards or guidelines that should be followed when using aluminum strips?

- <p>Yes, there are safety standards for using aluminum strips. These include ensuring that the aluminum is of the correct grade for its intended use, following guidelines for handling and storage to prevent contamination or damage, and adhering to regulations regarding worker safety, such as wearing appropriate personal protective equipment. Additionally, it's important to comply with local and international standards like ASTM or ISO specifications for aluminum products. Proper ventilation should be maintained during processing to avoid inhalation of dust or fumes, and safety measures should be taken to prevent fires, as aluminum can be a fire hazard in certain conditions.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

- Q: What is the standard thickness for aluminum strips and what is it commonly used for?

- <p>The thickness of aluminum strips can vary widely depending on their application, but common thicknesses range from 0.005 inches (0.127 mm) to 0.5 inches (12.7 mm). Aluminum strips are typically used in various industries such as construction, automotive, aerospace, and packaging. They are utilized for manufacturing parts, creating foils, and in applications requiring lightweight, strong, and corrosion-resistant materials.</p>

Send your message to us

2mm Stucco Embossed Aluminum Sheet Metal Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords