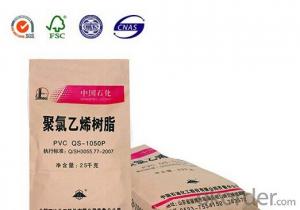

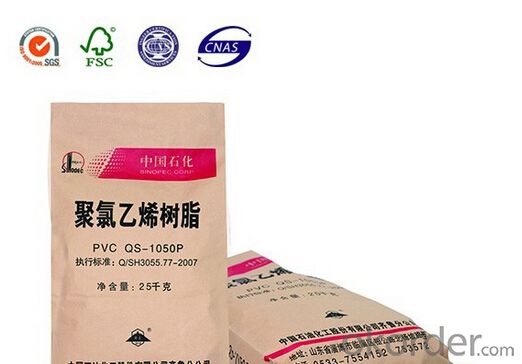

25kg White Kraft Paper Bag for Cement Paper Bag with Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

♥ More Descriptions for Our Kraft paper bag :

1.Kraft paper bag is a packaging container which made from composite material, non-toxic, tasteless, pollution-free.

2.It meets up with Uses Electromagnet Protection Standard, has the characteristics of high strength and high environmental protection.

3.For packing pulverous or granular material such as black carbon, xanthan- gum, charcoal, cement etc.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- Use the lighter directly on the other side of the metal label to burn for a while. The glue on the label will melt quickly. This method works fastest and works best, but it only works for metals.

- Q: What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q: What about the use of plastic bags?

- There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: Do vacuum packing bags have to be vacuum packed?

- To be exact, vacuum packing bags must have vacuum packaging machines to complete vacuum packaging. If you want to use vacuum packaging bags for non vacuum packaging (i.e. ordinary packing), you can also use them.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- On the basic price will be a little higher, the brittle is generally PP or PET is done, some relatively low grade. Soft is generally made of multi-layer coextrusion film, barrier, and feel good. This soft about 27000 yuan / ton, while the PP film generally as long as 17000 yuan / ton, ten thousand tons a difference.

- Q: What's the difference between plastic packaging bags and clothing bags?

- From film making, printing to bag making, there's a big difference. The clothes bag you say is just a bag of bags. There are several kinds of clothes bags I have used, and each machine needs different machines

- Q: Can aluminum packaging bags be recycled?

- Tetra Pak, Combibloc and other milk packaging (the two kinds of packaging are mainly China milk packaging, or packaging recycling separation Fangzhuan) technology has matured, the waste recycling plant can be decomposed into boxes: good pulp, aluminum, plastic, the cost also is (about 5 years ago to calculate), the current difficulties are: Chinese people's awareness of garbage is not strong due to high cost recovery (plus the current labor costs rise), in recent years a recycling plant is estimated to be closed, the state support in the tax area is likely to continue to;

- Q: What can be easily removed from the words printed on plastic bags?

- Plastic packaging is printed on the word if it is ordinary ink with thinner a wipe off, is not easy to erase the organic dye. Such dyes are colored substances. But a coloured substance is not necessarily a dye. What kind of dyes do you use on plastic bags?.

- Q: What is the difference between package material PETAL and VMPET?

- Packing material:PETAL represents the PET film composite pure aluminum sheet material. Packaging industry called aluminum foil filmVMPET represents an aluminized PET film, which is a high temperature vacuum in which the high purity metal aluminum is uniformly applied to the plastic film. The packaging industry is called aluminized film.

- Q: How many kinds of packing bags are there in the packaged foods?

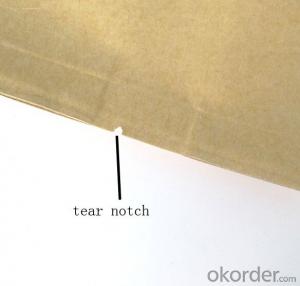

- PE's softness and mechanical properties are worse than those of PP. It represents shopping bags, plastic wrap, garbage bags and so on.PP is stiffer, anisotropic (with a notch that is easily ripped), has good mechanical properties, and is superior to PE in high-temperature performance, representing bread bags.I wonder if this answer has met your requirement.

Send your message to us

25kg White Kraft Paper Bag for Cement Paper Bag with Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches