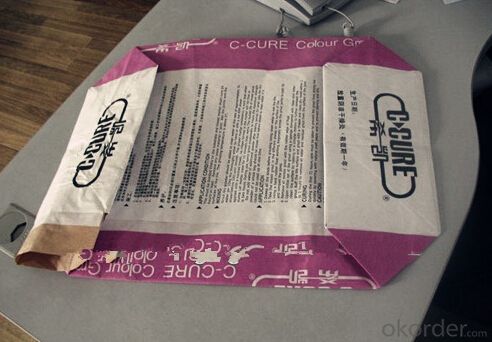

10KG Plastic Laminated Kraft Paper Valve Bag For Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

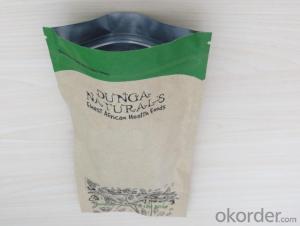

10/20/30KG Plastic Laminated Kraft Paper Valve Bag For Cement :

1>Customized Design, Style, Size, Window, Thickness. etc.

2>Rotogravure Printing for a vivid color;

3>Food Grade material;

4>Eye-catching on Shelf;

5>Resealable for many times;

6>Advertising and Packaging in one--Kill two birds with one stone;

7>Small Order is Available;

8>Tear Notch and Hang Hole are available;

9>Round Corner and K-seal are available.

- Q: What products need plastic packing bags?

- Electronic products, clothing products, industrial products, some medical products, food and so on. What kind of plastic bags are the key?.

- Q: What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- A good vacuum packing is recommended.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The ingredients of food reducing agents are some vitamins, phenols, iron powder and so on. Because these substances react readily with oxygen, they protect the food from being oxidized,

- Q: What kind of material is the food packing bag in general?

- Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon composite, CPP, or other composite.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: Is the color of cement packing bags related to cement?

- Portland ash cement, fly ash, silicate sleep and composite Portland cement -- black or blue.The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents.

- Q: What are the common materials of tea packing bags?

- Synthetic paper cans are the most widely used packaging materials at present. Their advantages are economical, light and beautiful. They are breathable, breathable, and should not be used alone. It is best to use PE bags or aluminium foil laminated bags for internal packing.

- Q: What's the difference between plastic packaging bags and clothing bags?

- From film making, printing to bag making, there's a big difference. The clothes bag you say is just a bag of bags. There are several kinds of clothes bags I have used, and each machine needs different machines

- Q: What kind of packaging bag does polysilicon use?

- Packing should be prevented from damage to polyethylene packing bags to avoid external contamination and provide good protection. It should be high pressure.

Send your message to us

10KG Plastic Laminated Kraft Paper Valve Bag For Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords