Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing are processing with imported materials ,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

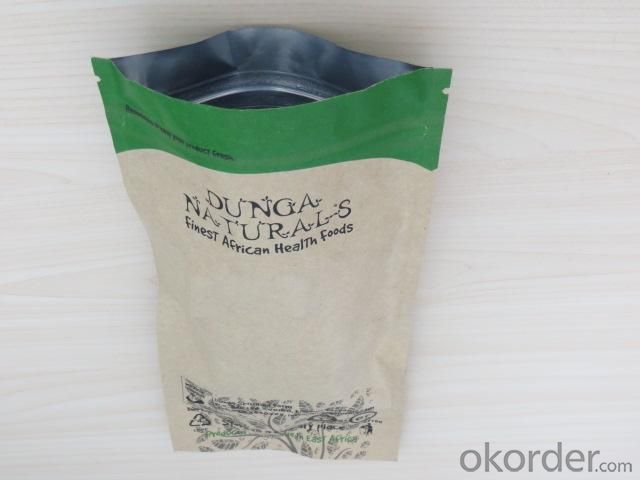

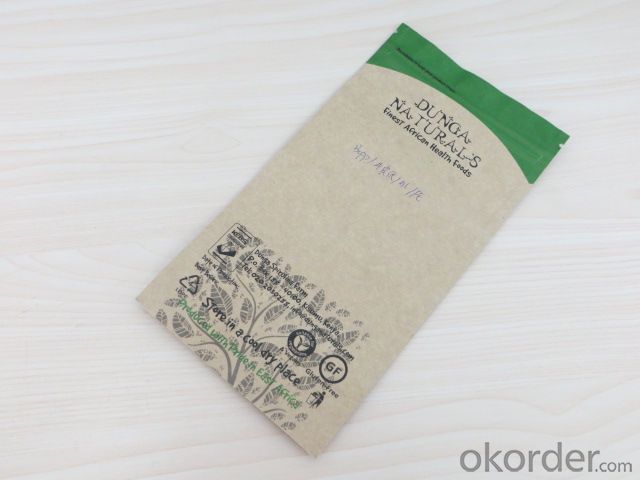

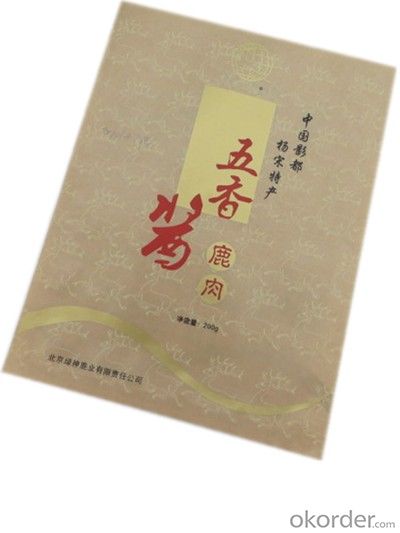

3. Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing Images:

4. Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: What's the raw material of the cement packing bag?

- Plastic recycling machine is the role of the crushed cleaning waste polypropylene, polyethylene block, sheet, pipe, bottle, film, weaving, silk, pressurized heated in the machine, drawing into strips, the cutter into granular for other plastic processing machinery use.

- Q: What's the packing of the air in the food package?

- Carbonated drinks are mostly filled with carbon dioxide gas CO2, and its own drinks are carbon dioxide ingredients in the majority, with CO2 replacement of the air, but also for the preservation of the product, to ensure the taste, but also improved the shelf life.In addition, some food packaging is filled with a certain proportion of mixed gas, may be O2+CO2+N2, N2+CO2, O2, +CO2. This is also based on the needs of different enterprises, different customers.

- Q: Is there any identification on the vacuum package?

- Laser inkjet printer, laser energy generator is the product surface engraved characters.

- Q: Dried fish vacuum packaging packing bag can not puncture

- Anti piercing vacuum packaging bags, first of all, choose the material of the bag to have toughness, followed by the thickness of the bag

- Q: Why are some teas not vacuum packed?

- In order to ensure the quality of tea and pure taste, natural, free from external conditions, but also in order to enhance the image of tea, enhance the value of goods, the exquisite packaging of tea is the trend of the times. These unsuitable vacuum packed tea, such as green tea and Longjing, tend to be easily squeezed and packed and can be packed in vacuum packed with nitrogen. Brick tea packaging paper bag packaging form form West Lake Longjing Tea vacuum tea vacuum packing inflatable packaging is a mixture of gases in vacuum and then filled with nitrogen, carbon dioxide and other two or three kinds of single gas or gas. Nitrogen is an inert gas with a density close to the air. It acts as a filling, keeping positive pressure in the bag and protecting the leaves from crushing by atmospheric pressure. Carbon dioxide can make tea into sleep, and maintain the quality of tea.

- Q: Should the food packaging bags be labeled with QS markers?

- Hello, you me to answer the question: is not needed, packaging bag manufacturers is the right to own QS logo printing to the packaging bag on your package, the most is according to your request will be posted to the QS carton outside (i.e. certificate below). Your bag can only be printed with your QS logo, or not printed.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q: Plastic packing bag printing color

- A few colors, that is, a few colors, with several roll, one color needs a roll, and the more colors you have, the higher the cost of making the plate. Of course, the plate is calculated by area, the greater the size of your area, the higher the cost of making.

- Q: How about the material difference of food packaging bag?

- Reason: PE has better heat sealing property, which is easy to sealPA has better printability and is used in the outer layer to print beautiful picturesPVDC EVOH, good separation performance, prevent oxidation. The film closed light is good, not easy to see the light of the product is appropriate.Specific more professional, no longer introduce one by one

Send your message to us

Laminated Kraft Paper Bag with Degassing Valve for Coffee Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords