2024 Lasted PPR Plastic Tubes for Industrial Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness:SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

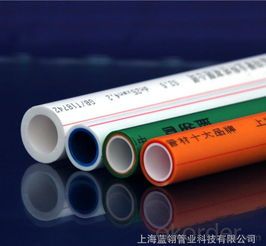

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What is the white plastic water pipe material commonly used in engineering?

- The white plastic water supply pipe commonly used in engineering is rigid PVC pipe (uPVC).UPvC tube has high impact resistance and chemical resistance. It can be added different additives according to the different requirements, so that it can meet the different requirements of physical and chemical properties. According to the structure form, they are divided into single wall tube, core layer foam pipe, radial reinforced pipe, spiral winding pipe, double wall corrugated pipe and so on.

- Q: How can the three plastic pipes be fixed in the installation quota?

- PVC pipe sleeve: rigid flame retardant pipe. Rigid PVC pipes and semi rigid flame retardant pipes are rarely used. One is for a roll, and for long distances.

- Q: How about plastic pipes for water pipes in the house? With PVC or PPR or something?

- PVCPVC pipe is divided into PVC, water supply and drainage pipe two kinds, with better tensile and compressive strength, but its flexibility is not as good as other plastic pipes. Used for municipal water supply and drainage, industrial water supply and drainage, civil water supply and drainage, irrigation, vegetation watering, etc..

- Q: When the concrete is poured into the concrete, the formwork is lined with white tubes. What is that for?

- Early wall bolt not used in casing, after the completion of concrete pouring in concrete wall bolt, the bolt ends exposed on the outside part of the concrete cut off, it directly resulted in the increase of cost. In recent years, in order to save the construction cost, so that the wall bolt can turnover, PVC plastic pipe for the bolt rope and then placed in the corresponding position within the template, after pouring concrete and reaches a certain intensity, can be pumped out by bolt.

- Q: Which companies manufacture GOOD QUALITY plastic and rubber tubing for use in a molecular biology lab, ie. for condensers, circulators, etc

- Look in Cole-Parmer catalog, or in Fisher scientific, or in VWR or....

- Q: Recently I've been treated, And i was taking the metro gel where the little plastic tubes are to be put inside you in order the get rid of BV around the same time i was told i was positive for chlamydia, and by then i had already wash the tube thoroughly with nothing but water and placed it in the box. I then stopped the process of the metro gel so that i could be cured for chlamydia. Last night i reused the same tube that i was using when i had chlamydia. Did i just re-contract chlamydia back into my body without intercourse. I was told intercourse was the only way to catch this disease? Did anyone else experience this?I already been to the doctor 3 times in one month, it is so embarrassing having to constantly go to the doctor about the same issue. that is why i'm on the net asking this very personal question, because i'm impatient and i must know now. does anyone have a positive, overly-confident answer?

- Relax, you're fine. A woman indeed may reinfect herself with chlamydia, but don't worry, this condition can be completely prevented. Chlamydia is sensitive to heat, the pathological bacterium can only live for 5~10 minutes in degree 50~60. Plus, away from our body, pathogen of chlamydia will die soon. Except for intercourse, clamydia can spread through sharing the infected toys. And for a certain condition, a pregnant woman can give chlamydia to her baby. Anyhow, do not have to worry about it, you'd be ok!

- Q: Is it supposed to come off easy? Do I buy a new one a long with a flapper? My toilet is constantly running and water is flowing into the bowl.

- yes, you can purchase the complete flushvalve at any plumbing supply place.(lowes, home depot etc....) very inexpensive, these now come with a complete rebuild kit or you have the option to buy parts seperate. try the brand fluidmaster, comes complete. you will need to remove the tank and reassemble with a new tank to bowl gasket and bolts - best luck

- Q: Can plastic tubes be used for HVAC systems?

- Yes, plastic tubes can be used for HVAC systems. They are commonly used for air conditioning and ventilation systems due to their lightweight, flexible, and corrosion-resistant properties. Plastic tubes are also cost-effective and easier to install compared to traditional metal ductwork.

- Q: What is the maximum temperature plastic tubes can withstand without deformation?

- The maximum temperature that plastic tubes can withstand without deformation varies depending on the specific type of plastic used. However, most common plastics can typically withstand temperatures ranging from 100 to 150 degrees Celsius without significant deformation. It is important to consult the manufacturer's specifications or conduct specific testing to determine the maximum temperature tolerance of a particular plastic tube.

- Q: There are these little LEDs in this necklace, and attached to the LED is a long narrow plastic tube that is very luminous and transmits light easily

- Those are called fiber optics, just like the link says in the title. Fiber optics can be made out of different materials and can be acquired and different places online and in stores, your probably looking for the cheap plastic fiber optics.

Send your message to us

2024 Lasted PPR Plastic Tubes for Industrial Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords