2024 Plastic Down Pipe for Renault Used in Industrial Application - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Products:

CNBM PPR pipes are designed for Hot and Cold water supply and heating applications and it is suitable for different applications listed below:

• Hot and cold water supply in residential,

industrial, commercial & public projects

• Solar applications

• Compressed air systems

• Drinking water and liquids

• Watering systems for greenhouses & gardens

• Transportation of aggressive fluids

PPR Pipe Size:

PN10 | PN12.5 | PN16 | PN20 |

32*3.0 | 32*3.6 | 32*4.4 | 32*5.4 |

40*3.7 | 40*4.5 | 40*5.5 | 40*6.7 |

63*5.8 | 63*7.1 | 63*8.6 | 63*10.5 |

75*6.9 | 75*8.4 | 75*10.3 | 75*12.5 |

90*8.2 | 90*10.1 | 90*12.3 | 90*15 |

110*10.1 | 110*12.3 | 110*15.1 | 110*18.3 |

Specification:

Products name | Tee with Tap Connector Male |

Material | PPR |

Field of Application | Water |

Work temperature | -10℃-110℃ |

Packing | standard export package or customized |

Function | Kitchen, home, commercial, garden and general |

Place of origin | Hebei China(mainland) |

Brand | CMAX |

Application:

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

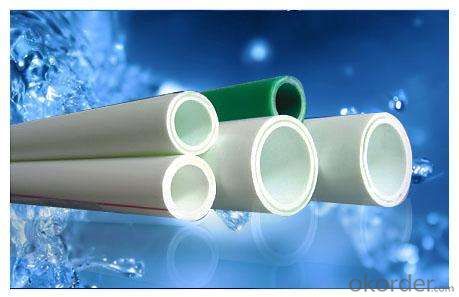

Product Feature:

1. High Temperature Resistance: the maximum sustained working temperature is up to 70°C , the maximum transient temperature is up to 95°C

2. Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe

3. Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

4. Corrosion Resistance: resist chemical matters and electron chemical corrosion

5.High Flow Capacity: smooth interior walls and low friction result in low flow resistance and high volume

6. Excellent Flexibility: can be supplied in coil

7. Longevity: more than 50 years under proper use

Product Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

Company Profile:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Supplier of small plastic tube containers for ointments?

- places like aromotherapy supplies and massage supplies.

- Q: Can plastic tubes be used for insulation?

- Yes, plastic tubes can be used for insulation, especially in applications such as plumbing or electrical systems where they provide an additional layer of protection and help prevent heat loss or condensation.

- Q: Can plastic tubes be used in high-pressure applications?

- Yes, plastic tubes can be used in high-pressure applications. However, the suitability of plastic tubes for high-pressure applications depends on the specific type of plastic and its pressure rating. Some plastic materials, such as reinforced nylon or high-density polyethylene (HDPE), are designed to withstand high pressure and can be used effectively in such applications. It is essential to consult the manufacturer's specifications and guidelines to ensure that the plastic tube chosen is suitable for the desired pressure range.

- Q: Plastic pipes have steam, how to handle dry?

- The plastic tube contains water vapor, which is cooled and condensed into the pipe.Suggested preservation scheme: sealed, preserved, or as dry as dry.Treatment plan: blow dryAs for sun dryingPut together with the desiccant

- Q: I cant find them online and i need some.

- Flavor Ice.

- Q: How can I clean my hookah pipe? I have a clear plastic medical tubing as the pipe (quick fix buy works great lol) and I can easily take it apart to clean BUT it's got tar stains inside the tube now, and I can't get the tar stains out of the plastic tube, I've tried bleach and some mild abrassive cleaners, even soap. Any tips?

- Use isopropyl alcohol (rubbing alcohol).

- Q: Can plastic tubes be used for pool installations?

- Yes, plastic tubes can be used for pool installations. They are commonly used for the plumbing system of pools to transport water to and from the pool, as well as for other pool-related purposes such as drainage and filtration systems. Plastic tubes are lightweight, durable, and resistant to corrosion, making them a suitable choice for pool installations.

- Q: How flexible are plastic tubes?

- Plastic tubes can vary in flexibility depending on the type and thickness of the plastic used. Some plastic tubes, such as those made from PVC or polyethylene, are relatively flexible and can be bent or twisted to a certain extent without breaking. However, the flexibility of plastic tubes is generally limited compared to other materials like rubber or silicone.

- Q: My mother is staying with me for a few weeks and was recently put on oxygen, which means a lot of clear plastic tubing. My one cat loves straws and rubberbands. I thought she was ignoring it but she chewed and ruined a long line. Does anyone have some behavioral techniques I can use to stop her from doing this? Thanks so much!

- I wouldn't normally suggest this, but a spray bottle of water would work well in this case. Spray the cat with a little water whenever he gets near the tubing. It won't hurt him, just startle him a bit, and he will soon learn.

- Q: What are the disadvantages of welded steel pipe and plastic pipe?. More points, bonus points

- The technology of this product determines its advantages and disadvantages. Generally, the welded steel pipe has high accuracy, uniform wall thickness, high brightness inside and outside the pipe (the surface brightness of the steel pipe surface determined by the steel plate), and can be arbitrarily fixed. Therefore, it reflects its economy and beauty in the application of high precision, medium and low pressure fluid.

Send your message to us

2024 Plastic Down Pipe for Renault Used in Industrial Application - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords