2016 SEAMLESS PIPE ASTMA106 from china manufacturer CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full series of products provides an easier access for one stop purchase

▲ Line pipe

▲ Tubing and casing

▲ L & M & H boiler tube

▲ Gas cylinder tube & pipe

▲ Mechanical & Structural pipe

▲ Ship-building tube & pipe

▲ Automobile tube & pipe

1、Structure of Seamless Pipe ASTM A106:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Seamless Pipe ASTM A106:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

● Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

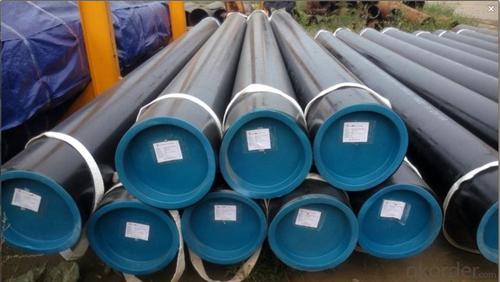

6、Seamless Pipe ASTM A106/53 Images:

- Q: What are the factors that affect the price of steel pipes?

- Some factors that can affect the price of steel pipes include the cost of raw materials, such as iron ore and other metals used in the production of steel, fluctuations in global steel demand and supply, transportation costs, market competition, and government regulations and tariffs. Other factors can include energy costs, labor costs, and the overall economic conditions of the countries involved in the steel industry.

- Q: How are steel pipes used in the fabrication of storage tanks?

- Due to their strength, durability, and versatility, steel pipes are widely employed in the construction of storage tanks. Throughout the tank fabrication process, these pipes serve various functions. To begin with, steel pipes are utilized in establishing the tank's foundation. By providing a robust base, they ensure stability and prevent potential structural problems. Moreover, steel pipes are employed in constructing the tank's shell. Through welding, these pipes are joined together to form a cylindrical structure capable of withstanding the pressure and weight of the stored material. Furthermore, steel pipes are crucial for installing inlet and outlet pipes. These pipes enable the controlled flow of materials in and out of the storage tank. Additionally, steel pipes frequently play a role in fabricating support structures within the tank. These structures distribute the weight of the stored material and offer additional reinforcement to the tank. When it comes to maintenance and repair, steel pipes are also essential. They are used to install access points such as manholes or inspection ports, facilitating routine inspections, cleaning, and any necessary repairs. In summary, steel pipes are indispensable in the fabrication of storage tanks, providing a resilient and dependable framework. They are employed in constructing the tank's foundation, shell, inlet and outlet pipes, support structures, and access points. With their durability and versatility, steel pipes ensure the integrity and functionality of storage tanks.

- Q: How do you prevent steel pipes from rusting?

- To prevent steel pipes from rusting, a common method is to apply a protective coating such as paint or epoxy. Additionally, regularly inspecting and maintaining the pipes, promptly repairing any damage or corrosion, and ensuring proper drainage to prevent moisture buildup are essential preventive measures.

- Q: How big is the seamless steel tube of DN50?

- This refers to the diameter of the steel pipe is 50 mm, DN50 steel pipe diameter is 60.3 mm, that is, 60.3 * 5 mm steel pipe

- Q: Can steel pipes be used for underground fuel storage tanks?

- Underground fuel storage tanks can indeed utilize steel pipes. These pipes find wide application in various fields, including underground fuel storage tanks. Their strength, durability, and resistance to corrosion enable them to serve as suitable long-term storage options for fuels like gasoline, diesel, and oil. Moreover, the weldability of steel pipes allows for the creation of seamless and secure tank structures. Nevertheless, it is crucial to ensure that the steel pipes employed in underground fuel storage tanks are appropriately coated with corrosion-resistant materials. This precautionary measure shields the pipes from potential damage that may arise due to exposure to moisture or the chemicals present in the fuel. Consistent inspection and maintenance procedures are also imperative to uphold the tank's integrity and avert leaks or environmental hazards.

- Q: How do you protect steel pipes from fire?

- To protect steel pipes from fire, there are several measures that can be taken. One commonly used method is to apply fire-resistant coatings or paints to the surface of the pipes. These coatings or paints are designed to withstand high temperatures and provide a barrier that prevents the heat from reaching the steel. Another effective way to protect steel pipes from fire is to wrap them with fire-resistant insulation materials. These materials act as a buffer, reducing the heat transfer and slowing down the spread of fire. Insulation materials such as mineral wool or ceramic fiber blankets are commonly used for this purpose. In addition, it is important to ensure that the steel pipes are properly installed and supported. This includes maintaining proper clearance from other flammable materials and avoiding overcrowding or obstructions that could impede the flow of air around the pipes. Adequate spacing between pipes is also crucial to prevent the transfer of heat from one pipe to another. Furthermore, it is recommended to incorporate firestop systems when steel pipes pass through fire-rated walls or floors. Firestop systems consist of fire-resistant materials and seals that prevent the spread of fire and smoke through openings or penetrations in fire-rated barriers. Regular maintenance and inspections are essential to ensure the ongoing effectiveness of the fire protection measures. Any damage or deterioration of the coatings, insulation, or firestop systems should be promptly repaired or replaced to maintain the fire resistance of the steel pipes. Overall, a combination of fire-resistant coatings, insulation, proper installation, and maintenance practices are crucial in protecting steel pipes from fire hazards. These measures help to minimize the risk of fire-related damage and ensure the safety of both the pipes and the surrounding environment.

- Q: Can steel pipes be used for underground water treatment systems?

- Certainly, underground water treatment systems can utilize steel pipes. Renowned for their durability, strength, and resistance to corrosion, steel pipes prove themselves suitable for a range of uses, including underground water treatment systems. They possess the ability to endure the pressure and environmental circumstances found underground, guaranteeing the secure and effective conveyance of water within the treatment system. Nevertheless, it is crucial to take into account the water quality and the likelihood of corrosion in the particular location when opting for the type of steel and implementing safeguarding measures, such as coatings or cathodic protection, to avert corrosion and ensure the pipes' longevity.

- Q: What is the role of steel pipes in the chemical manufacturing industry?

- Steel pipes play a crucial role in the chemical manufacturing industry as they are used for the transportation of various chemicals, both liquids and gases. The durability and resistance to corrosion of steel make it an ideal material for these pipes, ensuring the safe and efficient transfer of hazardous substances. Additionally, steel pipes are able to withstand high pressure and temperature conditions, allowing for the smooth operation of chemical processes.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- Seamless steel tube is formed during rolling. Welded steel pipes need to be welded after coiling, and spiral welding and direct welding are generally used. Seamless performance is better, of course, the price is higher.

- Q: Can steel pipes be used for steam systems?

- Yes, steel pipes can be used for steam systems. Steel pipes are commonly used in steam systems due to their high strength, durability, and heat resistance properties. Additionally, steel pipes can withstand high pressures and temperatures, making them suitable for transporting steam safely and efficiently.

Send your message to us

2016 SEAMLESS PIPE ASTMA106 from china manufacturer CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords