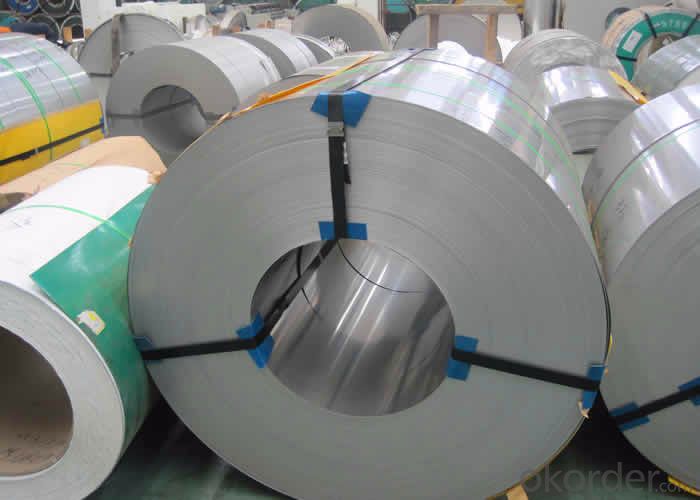

201 SERIOUS HOT ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 2B | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 2.5mm;3.0mm;4.0mm or as required | Width: | 485mm,510mm,600mm or as required | Place of Origin: | China (Mainland) |

| Brand Name: | CNBM | Model Number: | 201 | Type: | Coil |

| Application: | Decoration,Boiler Plate,Chemical Industry,Container plate,ship | Certification: | SGS,ISO | Color: | natural color |

| Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge | Features: | accurate dimensions |

| Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | DDQ: | slivery bright surface | Quality: | high quality Hot rolled stainless steel coil 201 |

| Stock: | Always in stock | Item: | Hot rolled stainless steel coil 201 |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement Hot rolled stainless steel coil 201 |

| Delivery Detail: | In 15 days |

Specifications

Hot rolled stainless steel coil 201

Width:485mm,510mm,600mm or as required

Thickness: 2.5mm;3.0mm;4.0mm or as required

Product Description

Stainless steel coil; stainless steel cold rolled coil;201 stainless steel coil; stainless steel coil

A. stainless steel coil

B. with competitive prices and fast delivery

C. High quality

Tisco 201 stainless steel coil

Thickness: 2.5mm;3.0mm;4.0mm or as required

Width: 485mm,510mm,600mm or as required

Length: As required

Material:201

201 stainless steel coil chemical composition

201 stainless steel coil | ||||||||

Grade | Chemical composition | |||||||

C | Si | Mn | P | S | Ni | N | Cr | |

% | % | % | % | % | % | % | % | |

201 | ≤0.15 | ≤0.75 | 5.5~7.50 | ≤0.060 | ≤0.030 | 3.50~5.50 | ≤0.25 | 16.00-18.00 |

201 stainless steel coil physical property

Physical Property | ||||

density | Strength of extension | yield strength | elongation | modulus of elasticity |

g/cm³ | psi | psi | % | psi |

7.93 | 100000-180000 | 50000-15000 | 55-60 | 29000000 |

Item | 201 stainless steel coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,430 |

Surface | NO.1,2b,4K,8k,HL,mirror finish |

Thickness | 0.3-100mm |

Width | 500-2000mm |

Price term | FOB,CFR,CIF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: Can stainless steel strips be used for architectural canopies?

- Yes, stainless steel strips can be used for architectural canopies. Stainless steel is known for its durability, strength, and resistance to corrosion, making it a popular choice for architectural applications. The strips can be shaped and fabricated to create unique and visually appealing canopies that offer protection from the elements while maintaining a sleek and modern aesthetic.

- Q: What are the common surface finishes for stainless steel strips?

- Stainless steel strips can be finished in different ways to achieve various appearances and functions. Here are some commonly used surface finishes: 1. Basic Finish: After being hot or cold rolled, stainless steel strips have a dull and non-reflective appearance, known as the mill finish. 2. Textured Finish: By brushing the stainless steel strip with abrasive materials, a textured appearance is achieved. This brushed finish helps to conceal surface imperfections and gives the strip a satin-like finish. 3. Reflective Finish: The stainless steel strip is mechanically polished, resulting in a smooth and reflective surface. This polished finish is often used for decorative purposes and is available in different levels of polish, such as mirror polish or satin polish. 4. Embossed Finish: To add texture and visual interest, the stainless steel strip is passed through embossing rollers, creating raised or sunken patterns on the surface. 5. Patterned Finish: Various techniques, like etching or laser engraving, can be used to create decorative patterns or designs on the surface of stainless steel strips. This gives the strip a unique and distinctive look. 6. Coated Finish: To enhance appearance or provide extra protection against corrosion, a thin layer of another material, such as a polymer or a metal, can be applied to the stainless steel strip. These finishes cater to different applications, offering a range of aesthetics and functionality.

- Q: Are 111 stainless steel strips magnetic?

- Indeed, 111 stainless steel strips possess magnetism. Stainless steel, a collective term for alloys with at least 10.5% chromium content by mass, is known for its resistance to corrosion and tarnishing due to the addition of chromium. Nonetheless, specific grades like the 111 series retain magnetic characteristics. This is attributed to the inclusion of other elements like nickel and manganese in the alloy, enabling magnetism. As a result, 111 stainless steel strips can be attracted to magnets and display magnetic properties.

- Q: Can stainless steel strips be used in chemical processing industries?

- Yes, stainless steel strips can be used in chemical processing industries. Stainless steel is highly resistant to corrosion and can withstand extreme temperatures, making it an ideal material for chemical processing applications. It is commonly used in the construction of tanks, piping systems, heat exchangers, and other equipment that come into contact with corrosive chemicals. Stainless steel strips are often used for fabricating these components due to their versatility and ability to be easily formed into different shapes and sizes. Additionally, stainless steel is known for its hygienic properties, making it suitable for industries that require strict cleanliness and sanitation standards. Overall, stainless steel strips are a reliable and durable choice for chemical processing industries.

- Q: How do stainless steel strips handle exposure to chemicals?

- Stainless steel strips are highly resistant to the effects of exposure to chemicals. This is due to the inherent properties of stainless steel, which include high corrosion resistance and the ability to withstand a wide range of chemical substances. Stainless steel contains a minimum of 10.5% chromium, which forms a passive, self-repairing oxide layer on the surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing the steel from reacting with chemicals and thus preserving its integrity. Additionally, stainless steel contains other elements such as nickel and molybdenum, which further enhance its resistance to chemical attack. As a result, stainless steel strips are widely used in industries where they come into contact with various chemicals, such as pharmaceuticals, food processing, and chemical manufacturing. They can withstand exposure to acids, alkalis, solvents, and other corrosive substances, maintaining their strength and durability over time. However, it is important to note that the exact resistance of stainless steel to specific chemicals may vary, and it is advisable to consult the manufacturer or refer to corrosion resistance charts for more detailed information on the compatibility of stainless steel with specific chemicals.

- Q: Are 111 stainless steel strips suitable for decorative applications?

- Indeed, decorative applications can indeed benefit from the suitability of 111 stainless steel strips. Renowned for its corrosion resistance, durability, and aesthetic charm, stainless steel has gained popularity in the realm of decorative purposes. The utilization of grade 111 stainless steel is prevalent in architectural and interior design ventures, including wall cladding, signage, furniture, and decorative trims. Its sleek and contemporary appearance, with a smooth and reflective surface, can effortlessly enhance any given area. Furthermore, the practicality of stainless steel is evident through its easy cleaning and maintenance, rendering it an ideal choice for decorative applications in both residential and commercial settings.

- Q: Can stainless steel strips be used in architectural applications?

- Yes, stainless steel strips can be used in architectural applications. Stainless steel is a versatile material that offers a range of benefits suitable for architectural projects. It is known for its corrosion resistance, durability, and aesthetic appeal. Stainless steel strips can be used in various architectural elements such as cladding, roofing, handrails, decorative panels, and trim. They can be fabricated into different shapes and sizes to meet specific design requirements. Stainless steel strips also offer flexibility in terms of finishes, allowing architects to achieve different looks and textures. Overall, stainless steel strips are a popular choice in architectural applications due to their strength, longevity, and ability to withstand harsh environmental conditions.

- Q: Can 111 stainless steel strips be annealed for improved ductility?

- Yes, 111 stainless steel strips can be annealed for improved ductility.

- Q: Are stainless steel strips suitable for electrical enclosures?

- Yes, stainless steel strips are suitable for electrical enclosures. Stainless steel is known for its corrosion resistance, durability, and excellent mechanical properties, making it an ideal material for protecting electrical components from external factors such as moisture, dust, and physical impacts. Additionally, stainless steel's high thermal conductivity allows for effective heat dissipation, ensuring the safe operation of electrical equipment inside the enclosure.

- Q: Can stainless steel strips be used in medical applications?

- Stainless steel strips possess the capability to be utilized in medical applications. The utilization of stainless steel is prevalent in the medical field owing to its exceptional resistance against corrosion, high durability, and ease of being sterilized. Various medical devices and equipment, such as surgical tools, implants, dental instruments, and medical tubing, commonly employ stainless steel strips. The material's capacity to endure high temperatures and resist corrosion makes it an ideal choice for applications emphasizing cleanliness and sterility. Furthermore, stainless steel is biocompatible, ensuring it does not provoke any negative reactions upon contact with living tissue. On the whole, stainless steel strips are a suitable option for medical applications due to their strength, dependability, and compatibility with the human body.

Send your message to us

201 SERIOUS HOT ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords