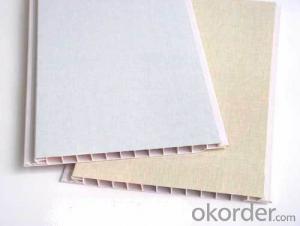

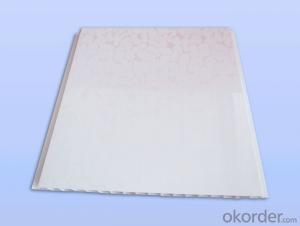

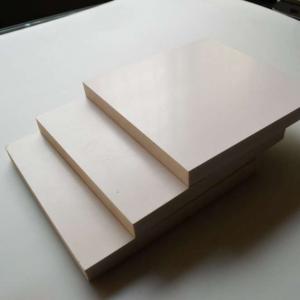

18mm WPC PVC Foam Board Plastic Sheets (Wood+Plastic Composites) for Cabinet Furniture Decorative

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

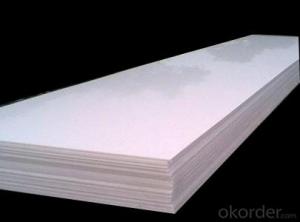

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.The PVC foam board is made through foaming and pressing into shape with additive.

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface,

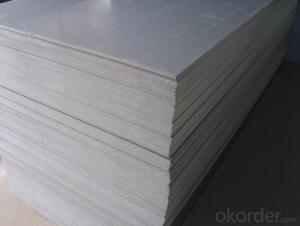

Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Density:0.35-0.9

Usage life:more than 50 years

Water absorption:<1.0%< p="">

Shape:Customer's Demand

Product Features

Features and Benefits

•Good screw and staple retention

• Superior UV package for extended outdoor life (white)

• Optimally designed for digital printing

• Bright white, smooth and uniform surface

• Available in a wide range of standard and special designer colors

• Standard matt or gloss finishes

• Good insulation, lower heat transmission

• Non-toxic

• Flammability: self- extinguishing

• Easily worked with conventional tools,prints and paints

• Easily bonded, formed, nailed and bolted

• Low water absorption

• High chemical resistance

Pictures of Factory

- Q: I am working on case modding my wii and I want to cut a stenciled design out of the plastic on the side. Is there a certain tool that can do this eficiently? im not sure a dremel would work with such an intricuite design (sorry for spelling) so which tool should i use?

- Anthony, I would use a spray glue (sold in the glue section of most stores) and spray the adhesive to the stencil and then apply to the plastic. It's simple to do, just follow directions on the can. Then if you have access to a scrollsaw, you can use a fine blade and cut the design with little trouble, no matter how intricate the design. Of course if you're unable to lay the area onto the flat surface of the scrollsaw, this won't be an option. If you use a dremel, it will be very difficult to follow the lines, plus it will leave a melted area along the cut lines. you could try using a plastic cutting knife, but if the detail is intricate, you won't have very good control. If the plastic is thick, it probably won't cut through the material. You may be able to use a coping saw, if the throat on the saw will clear the side of the plastic so you can cut it. You'd have to drill a starting point for the blade to enter. If the throat is not wide enough on the saw, try removing the blade from the saw and use it without the saw. The blade is very fine and should cut the material, including the intricate areas. That's about they only reliable ideas I can muster. Perhaps someone else has some ideas. good luck

- Q: I must be having a brain fart! I can't remember why I bought six rolls of duck tape and heavy gauge plastic sheeting. I remember that it had something to do with the Y2K scare but what the hell? Can someone refresh my memory, please?

- Save them for 2012.

- Q: Are plastic sheets resistant to moisture or humidity?

- Yes, plastic sheets are generally resistant to moisture or humidity.

- Q: Are plastic sheets resistant to warping under heat?

- Yes, plastic sheets are generally resistant to warping under heat.

- Q: How long do plastic sheets typically last?

- The lifespan of plastic sheets can vary depending on various factors such as the quality of the material, environmental conditions, and usage. However, on average, plastic sheets can last anywhere from 5 to 20 years.

- Q: What is the purpose of using plastic sheets?

- The purpose of using plastic sheets is to provide a protective barrier, insulation, or containment for various purposes, such as covering surfaces, protecting from weather elements, preventing dust or debris accumulation, or creating barriers for safety or privacy.

- Q: How do plastic sheets handle folding without breaking?

- Plastic sheets are designed to be flexible and durable, allowing them to withstand folding without breaking. The molecular structure of plastic enables it to stretch and bend without losing its integrity. Additionally, certain types of plastic, such as polyethylene and polypropylene, have a high resistance to impact and can further withstand folding without breaking.

- Q: Where can I buy Mylar sheets? I would like to make some stencils out of them. Also, I highly doubt it, but can these sheets be printed on, by a printer?

- You okorder , they have it in rolls. You should also be able to have a printer print on it. Not sure if all printers can so you might have to call around to find one but I'm sure that they can print on it.

- Q: I'm looking for a sheet of clear plastic to go on the back of a picture frame.It needs to be about 110cm by 60 cm and I suppose abut 3-4 mm thick.Basically the same as you'd use as the glass bit on the front of a frame.What should I be looking for? Perspex,acrylic?Any ideas on cost or what types of places to look for would art shops do this sort of thing?Any ideas welcome, I'm in Liverpool in the UK but general guidance needed too!Thanks.

- Afraid I really don't have a good answer to your question, but I do know that one photography trick for shooting through glass is to go to a thrift store or something and get a nice, unscratched piece of glass from a picture frame because supposedly the glass is glare free. Hopefully that helps you narrow down your search a little. A search for Liverpool Plastics brings up quite a few different businesses with phone numbers in your area. I'm not sure what kind of minimum order they might have, or how knowledgeable or time restricted the person on the phone might be, but it seems like it would be worth a shot to try that route. Online shipping charges can get pretty steep pretty quick.

- Q: Can plastic sheets be used for storm windows?

- Yes, plastic sheets can be used for storm windows. Plastic sheets are often used as a cost-effective and temporary solution for creating a barrier against drafts and cold air during storms. They can be easily installed and provide additional insulation to windows, reducing heat loss and improving energy efficiency. However, it is important to note that plastic sheets may not be as durable or long-lasting as traditional storm windows made of glass or plexiglass.

Send your message to us

18mm WPC PVC Foam Board Plastic Sheets (Wood+Plastic Composites) for Cabinet Furniture Decorative

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords