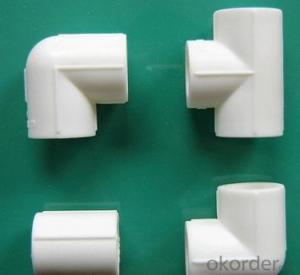

15mm PPR Elbows for Industrial and Agricultural Fields Plastic Water Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Advantanges

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

1. Can you find a translator for me?

You can tell us which language you speak, we will find the translator for you, and will be together work.

2. If we want to develop some new item, but maybe we just have some ideas, how can you do?

We can make new mold base on your idea, generally, if your quantity is more enough, we can refund the mold cost to you.

3. How Long Is Delivery?

Delivery time will be 30-45 days according to order quantity.

4.What Is Our Normal Payments Terms?

Our normal payment terms: T/T, L/C or western union

- Q: Are plastic pipe fittings compatible with different types of piping materials?

- Yes, plastic pipe fittings are generally compatible with different types of piping materials. They can be used with various materials such as PVC, CPVC, PEX, and polyethylene pipes, offering versatility and ease of installation. However, it is important to consider the specific manufacturer's guidelines and compatibility charts to ensure proper fittings are used for each specific piping material.

- Q: Can plastic pipe fittings be used for mining operations?

- Yes, plastic pipe fittings can be used for mining operations. Plastic fittings are often preferred in mining operations due to their corrosion resistance, lightweight nature, and ease of installation. They can effectively handle various mining applications such as transporting water, slurries, and chemicals. Additionally, plastic fittings are cost-effective and durable, making them a suitable choice for mining operations.

- Q: Can plastic pipe fittings be used for oil refinery processes?

- Yes, plastic pipe fittings can be used for certain oil refinery processes, particularly those that involve non-corrosive or non-hazardous fluids at lower pressures and temperatures. However, for processes involving corrosive chemicals, high temperatures, or high pressures, it is recommended to use more durable materials such as stainless steel or other metal alloys.

- Q: Can plastic pipe fittings be used in wastewater systems?

- Yes, plastic pipe fittings can be used in wastewater systems. Plastic fittings are commonly used in wastewater systems due to their durability, resistance to corrosion, and affordability. They are capable of withstanding the harsh chemicals and high temperatures often present in wastewater systems. Additionally, plastic fittings are easy to install and require minimal maintenance, making them a popular choice for wastewater applications.

- Q: How to calculate joint parts for hot melt connection of water supply plastic pipe?

- The hot melt connection directly connects the pipe and does not need the fittings

- Q: Can plastic pipe fittings be used in fountain systems?

- Yes, plastic pipe fittings can be used in fountain systems. Plastic fittings are commonly used in fountain systems due to their durability, resistance to corrosion, and easy installation. They are also cost-effective and can be found in various sizes and shapes to accommodate different fountain designs.

- Q: How do you connect plastic pipe fittings to galvanized steel pipes?

- To connect plastic pipe fittings to galvanized steel pipes, you can use a transition fitting specifically designed for this purpose. These fittings typically have a plastic end that can be connected to the plastic pipe and a threaded end that can be screwed onto the galvanized steel pipe. By using a transition fitting, you can ensure a secure and leak-free connection between the two different materials.

- Q: Are plastic pipe fittings easy to install?

- Yes, plastic pipe fittings are generally easy to install. They are lightweight, require no special tools, and can be quickly connected using simple techniques like solvent welding, compression fittings, or push-to-connect systems. Additionally, plastic pipe fittings are versatile and can be installed in various plumbing and water supply applications.

- Q: How do plastic pipe fittings compare to ductile iron fittings?

- Plastic pipe fittings offer several advantages over ductile iron fittings. Plastic fittings are typically lighter, easier to handle, and require less labor to install. They are also resistant to corrosion and chemicals, making them suitable for a wide range of applications. Additionally, plastic fittings are more cost-effective and have a longer lifespan compared to ductile iron fittings.

- Q: Are plastic pipe fittings compatible with different pipe materials?

- No, plastic pipe fittings are generally not compatible with different pipe materials.

Send your message to us

15mm PPR Elbows for Industrial and Agricultural Fields Plastic Water Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords