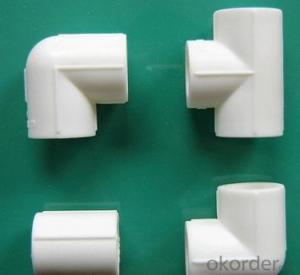

Plastic Water Pipe Fittings UK - New PPR Elbows Fittings for Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Advantages

1.We named this kind of fittings as PPR reducing sleeve. ppr reducing coupling

2.A whole part of this PPR reducing sleeve is made of polypropylene.

3.As you know, all the fitting designed for connecting the pipe or change the piping path. This PPR reducing sleeve is able to connect the different diameter pipeline together. I believe you know how to use it.

4.All of these PPR pipe fitting come in 3 different colors: white, gray, green.

5.Our PPR pipe fitting had been pasted the ISO9001 authentication. And had been got the CE certification.

6.These PPR reducing sleeve makes use of completely 100% new PPR material import from Korea. To be ensured that it is much healthier than the pipe make use of the reclaim plastic.

7.We adopt the newest technology in the piping produce industry.

8.We had been piping manufacturer for over 10 years. And we are good at this.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Are plastic pipe fittings resistant to thermal expansion and contraction?

- Yes, plastic pipe fittings are generally resistant to thermal expansion and contraction. They are designed to withstand temperature changes without significant deformation or damage. However, it is important to choose the appropriate type of plastic material for the specific application and consider the temperature limits specified by the manufacturer to ensure optimal performance.

- Q: What are the common applications for plastic pipe fittings?

- Plastic pipe fittings are commonly used in various applications such as plumbing systems, irrigation systems, water supply networks, and wastewater management. They are also employed in industries like agriculture, construction, and manufacturing, where they play a crucial role in conveying fluids and gases efficiently and securely. Additionally, plastic pipe fittings are often used in residential and commercial buildings for connecting and directing water, gas, and other liquids to appliances and fixtures.

- Q: Are plastic pipe fittings suitable for use in breweries and distilleries?

- Yes, plastic pipe fittings are suitable for use in breweries and distilleries. They are commonly used in these industries due to their excellent resistance to chemicals, corrosion, and temperature variations. Additionally, plastic pipe fittings are lightweight, easy to install, and cost-effective, making them a popular choice for various applications in breweries and distilleries.

- Q: Can plastic pipe fittings be used in vacuum systems?

- No, plastic pipe fittings are generally not suitable for use in vacuum systems as they may not be able to withstand the high levels of negative pressure and can potentially deform or fail under such conditions.

- Q: Are plastic pipe fittings resistant to extreme temperatures?

- Yes, plastic pipe fittings are typically resistant to extreme temperatures. They can withstand both high and low temperatures, making them suitable for various applications.

- Q: Are plastic pipe fittings resistant to acid solutions?

- Yes, plastic pipe fittings are generally resistant to acid solutions.

- Q: Can plastic pipe fittings be used for cooling water systems?

- Yes, plastic pipe fittings can be used for cooling water systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ability to handle high flow rates. Additionally, plastic fittings are lightweight and easy to install, making them a cost-effective choice for cooling water applications.

- Q: Can plastic pipe fittings be glued together?

- Yes, plastic pipe fittings can be glued together using specific adhesive designed for plastic pipes.

- Q: Can plastic pipe fittings be used in sprinkler systems?

- Yes, plastic pipe fittings can be used in sprinkler systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Additionally, plastic fittings are easier to install and require less maintenance compared to traditional metal fittings.

- Q: Can plastic pipe fittings be used for water distribution networks?

- Yes, plastic pipe fittings can be used for water distribution networks. Plastic pipes and fittings, such as PVC or HDPE, are commonly used in water distribution systems due to their durability, corrosion resistance, and affordability. These fittings are designed to meet specific industry standards and regulations, ensuring safe and reliable water distribution. However, it is important to choose fittings that are compatible with the specific requirements of the water network and adhere to local plumbing codes and regulations.

Send your message to us

Plastic Water Pipe Fittings UK - New PPR Elbows Fittings for Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords