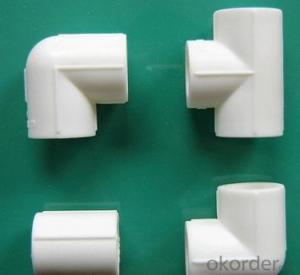

Electrical Plastic Pipe Fittings - PPR Elbows for Industrial and Agricultural Fields Made in China Professional

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

1. Can you find a translator for me?

You can tell us which language you speak, we will find the translator for you, and will be together work.

2. If we want to develop some new item, but maybe we just have some ideas, how can you do?

We can make new mold base on your idea, generally, if your quantity is more enough, we can refund the mold cost to you.

3. How Long Is Delivery?

Delivery time will be 30-45 days according to order quantity.

4.What Is Our Normal Payments Terms?

Our normal payment terms: T/T, L/C or western union

- Q: Can plastic pipe fittings be used for hydrogen gas storage?

- No, plastic pipe fittings cannot be used for hydrogen gas storage. Hydrogen gas is highly reactive and can cause degradation and embrittlement of plastic materials, leading to potential leaks and safety hazards. It is recommended to use materials like metal alloys or composite materials specifically designed for hydrogen gas storage.

- Q: Are plastic pipe fittings compatible with compression couplings?

- Yes, plastic pipe fittings are compatible with compression couplings.

- Q: What are the common materials used for plastic pipe fittings?

- Common materials used for plastic pipe fittings include polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polypropylene (PP), and polyethylene (PE).

- Q: Can plastic pipe fittings be used for underground irrigation systems?

- Yes, plastic pipe fittings can be used for underground irrigation systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation.

- Q: Can plastic pipe fittings be used for air conditioning systems?

- Yes, plastic pipe fittings can be used for air conditioning systems. Plastic materials such as PVC or CPVC are commonly used in air conditioning systems due to their corrosion resistance, durability, and ease of installation. However, it is important to ensure that the specific plastic material and fittings chosen are suitable for the pressure and temperature requirements of the air conditioning system.

- Q: Are plastic pipe fittings resistant to clogging and scaling?

- Yes, plastic pipe fittings are generally resistant to clogging and scaling. The smooth inner surface of plastic pipes minimizes the accumulation of debris and sediment that can lead to clogs. Additionally, plastic materials are less prone to scaling caused by mineral deposits compared to metal pipe fittings.

- Q: Method for using steel wire mesh skeleton plastic composite pipe

- Welding replacement of electric melting pipe fittings, must ensure that the pipeline without water retention, otherwise it is difficult to weld the fused pipe solid.

- Q: What materials are plastic pipe fittings made of?

- Plastic pipe fittings are commonly made from materials such as PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PEX (cross-linked polyethylene), and PP (polypropylene).

- Q: Are plastic pipe fittings suitable for food processing industries?

- No, plastic pipe fittings are not suitable for food processing industries as the chemicals leaching from the plastic can contaminate the food and pose a health risk.

- Q: Can plastic pipe fittings be used for swimming pool filtration?

- Yes, plastic pipe fittings can be used for swimming pool filtration. They are commonly used in pool plumbing systems and offer durability, corrosion resistance, and easy installation.

Send your message to us

Electrical Plastic Pipe Fittings - PPR Elbows for Industrial and Agricultural Fields Made in China Professional

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords