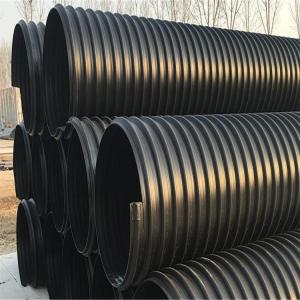

Plastic Pipe Push Fittings Steel Mesh Skeleton PE Pipe for Underground Coal Mine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Material: | Specification: | Length: | |||

| Thickness: | Standard: | Pressure: | |||

| Color: | OEM: | Working life: | |||

| Feature: | bending property: | Application: | |||

| Origin: | Production Techinque: | Ranking: |

Specifications

1.superior wearability

2.superior temperature resistant

3.superior impact resistant

Applications scope:

steel mesh skeleton PE composite Pipe can use in chemical industry :manufacture industry of acid ,alkali and salt ;transmission or discharging pipeline of corrosive gas, fluid and solid powder in industries including petrochemical,fertilizer,persticide,pharmacy,chemical,mining,plastic and rubber industry.

Oil and gas fields: oil-contained wastewater, gas field misture, polymer liquor reinjection to oil well, twice and triple oil extraction and transmission pipelines.

Mines: ore pulp, tailings, vent pipes and engineering pipes.

Texitile, printing, dyeing and paper industry: transmission or discharging pipeline to transport corrosive media.

Municipal constructions: transmission pipelines of constructional water supply and drainage, drinking water, natural gas and fuel gas.

Non-ferrous metal: seawater transmission, underdrain transmission pipe, discharging pipes and irrigation water pipe, etc.

Agriculture: deep-well pipes, strainer pipes, underdrain transmission pipe, discharging pipes and irrigation water used in desalinator, seaside power plant and port cities.

Thermoelectricity engineering: process water, recycled water and waste residue transmission in thermoelectricity projects.

Express highway: underground drainpipes and cable conduits.

.

Heat Preservation:

steel mesh skeleton PE composite Pipe not less than 25mm in thickness are used to wrap around pipeline surface. Buried under ground, it will not absorb water and distort, thus its service life keeps the same with the pipeline.

- Q: Can plastic pipe fittings be used for hydrogen gas storage?

- No, plastic pipe fittings cannot be used for hydrogen gas storage as hydrogen is a highly flammable gas and can permeate through plastic materials, leading to potential leaks and safety hazards.

- Q: Are plastic pipe fittings resistant to high temperatures?

- Yes, plastic pipe fittings can be resistant to high temperatures, but it depends on the specific type of plastic used in their construction. Some plastic materials, such as CPVC (chlorinated polyvinyl chloride) or PEX (cross-linked polyethylene), are designed to withstand high temperatures and are commonly used in hot water systems. However, other types of plastic pipe fittings may have lower temperature limits, so it is important to check the manufacturer's specifications to ensure their suitability for high-temperature applications.

- Q: Do plastic pipe fittings have a maximum operating temperature?

- Yes, plastic pipe fittings have a maximum operating temperature. The maximum temperature varies depending on the type of plastic used in the fittings. It is important to consult the manufacturer's specifications to ensure that the fittings are compatible with the intended temperature range.

- Q: Can plastic pipe fittings be used for irrigation systems?

- Yes, plastic pipe fittings can be used for irrigation systems. They are commonly used due to their durability, corrosion resistance, and cost-effectiveness. Additionally, plastic fittings are easy to install and can be used with various types of plastic pipes, making them a popular choice for irrigation systems.

- Q: Can plastic pipe fittings be used in hydronic heating systems?

- Yes, plastic pipe fittings can be used in hydronic heating systems. Plastic fittings, such as those made from PVC or PEX, are commonly used in hydronic heating systems due to their durability, corrosion resistance, and ease of installation. They are suitable for transporting both hot and cold water, making them a reliable choice for hydronic heating applications.

- Q: Can plastic pipe fittings be used in vacuum systems?

- Yes, plastic pipe fittings can be used in vacuum systems. However, it is important to consider the specific requirements and limitations of the vacuum system, such as the level of vacuum, temperature, and chemical compatibility. Some plastic materials may not be suitable for high vacuum applications or may have limited temperature or chemical resistance. It is recommended to consult with experts or manufacturers to ensure the selected plastic pipe fittings are appropriate for the specific vacuum system.

- Q: Are plastic pipe fittings durable?

- Yes, plastic pipe fittings are generally durable and long-lasting. They are resistant to corrosion, chemicals, and UV radiation, making them suitable for a wide range of applications. However, the durability of plastic pipe fittings can vary depending on the type of plastic used and the specific conditions they are exposed to.

- Q: Can plastic pipe fittings be used for chemical storage facilities?

- No, plastic pipe fittings are not suitable for chemical storage facilities as they are not resistant to the corrosive properties of many chemicals.

- Q: Can plastic pipe fittings be used for plumbing in mobile homes?

- Yes, plastic pipe fittings can be used for plumbing in mobile homes. In fact, the use of plastic pipe fittings is quite common in mobile home plumbing due to their durability, affordability, and resistance to corrosion.

- Q: Can plastic pipe fittings be used for water distribution networks?

- Yes, plastic pipe fittings can be used for water distribution networks. Plastic pipes and fittings, such as PVC or HDPE, are commonly used in water distribution systems due to their durability, flexibility, and resistance to corrosion. These fittings provide a reliable and cost-effective solution for transporting water safely and efficiently.

Send your message to us

Plastic Pipe Push Fittings Steel Mesh Skeleton PE Pipe for Underground Coal Mine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords