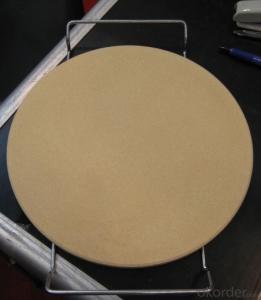

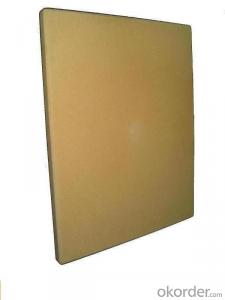

High Alumina Brick 15' Round Hot Sale Pizza Stone for Cooking Pizza

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000

- Supply Capability:

- 20000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1,Foshan ceramic pizza stone

2,Color:Yellow/White;

3,Heat resistant;

4,Durable and eco-friendly materials

Special size/shape/color can be made according to your design/requirement.

Description | 15'round hot sale pizza stone |

Color | Yellow/white |

Dimensions | Dia15' |

Ideal Thickness | 11-13mm |

Certification | FDA,RoHS,SGS,LFGB,etc. |

Remark | logo/text excluded |

Our qualified baking stones are made of cordierite, which is eco-friendly and free of heavy metals, cadmium, lead as well as other harmful substance.It can be used in either conventional oven,microwave oven,or directly on the fire.Its working temperature is 1000°c and it would not crack no matter how extremely change of the temperature.

It helps to distribute the heat of the oven evenly to your pizza and absorb excess moisture creating a crisper crust.

By the way,it's not only ideal for baking pizza but also foccacia,french bread,croissants,cookies,biscuits,and more,just use your imagination

- Q: What is the heat preservation material used in a laboratory furnace?

- Asbestos, high alumina brick, or carbonized silicon are often used.Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

Send your message to us

High Alumina Brick 15' Round Hot Sale Pizza Stone for Cooking Pizza

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000

- Supply Capability:

- 20000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords