1260C Low Thermal Conductivity Ceramic Fiber Blanket for High Temperature Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HZ (High Zirconium) | Application: | Liners Of Industrial Furnace | Thickness: | 6-60mm |

| Width: | 610/1220mm | Length: | 3600/7200/14640mm | Chemical Composition: | Al2O3: 39-40% Zr02:15-17% |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1050C | Fiber Diameter: | 3-5um |

| Shrinkage (1800 ℉, 3h): | -3% | Thermal Conductivity: | 0.09-0.16w/(m.k) | Density (kg/m³ ): | 96 |

| Model Number: | JK-ceramic fiber1260S-002 | Brand Name: | Place of Origin: | China (Mainland) | |

| color: | pure white | certificate: | CE ISO9001 | size: | customizable |

| sample: | available |

Packaging & Delivery

| Packaging Detail: | 1. Plastic bag inside and woven bag out side, 620rolls/1x40HQ 2. Plastic bag inside and carton out side, 525ctns/1x40HQ |

| Delivery Detail: | 3-15 days |

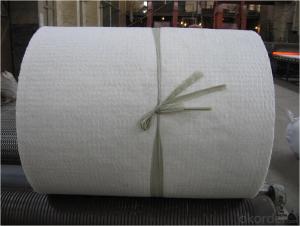

1260C Low Thermal Conductivity

Ceramic Fiber Blanket for High Temperature Kiln

Product Description

Ceramic Fiber Blanket

Ceramic Fiber Blanket is made of special ceramic longfiber that is produced by the melting of very pure raw materials in double surface meeding process without binders and with good stability in a large range of temperature.

The process of double surface needing increase interweaving and tensile strength. Ceramic fiber blanket is a needled blanket that has exceptional handling strength, while being flexible and lightweight. Ceramic Fiber Blanket is made of high purity Alumino-Silicate (and Zirconia) fibrous wool.

Product Information of Ceramic fiber blanket

Item |

Ceramic fiber blanket |

Classification Temperature

|

1100C 1260C 1420C 1600C |

Features of Ceramic fiber blanket |

v Needled blanket v Non-combustible v Low thermal conductivity v Shorter heat up and cool down time v Resilience and resistance to thermal shock v Flexible and easy to cut or install v Consist of acoustic properties v Contain no organic binder v Asbestos free v Resistance to burning v Low thermal capacity v Good insulation v Good obstructing voice and mechanism strength v Low shrinkage v Good springiness for fibers v Convenient producing and installing

|

Application of Ceramic fiber blanket |

v Refractory back-up installation v Direct exposure to heat as furnace hot face lining v Expansion joint seal v Fire protection v General high temperature insulation v Lining for furnaces, kiln and oven v Expansion joints and seals for furnace, kiln and oven v Back-up installation v Lagging of high temperature pipe work v High temperature filtration v Steam turbine and nuclear insulation v Fire protection |

-Professional high temperature furnaces Manufacture We have being specialized in producing high temperature furnaces for more than 10 years, and all our products are exported.

--Guaranteed Quality Our furnaces are warranted to be free from defects in materials or workmanship for 2 years from the date of purchase. Within this period, Across International will, at its sole options, replace any components that fail in normal use. Such replacement will be made at no charge to the customer for parts, provided that the customer shall be responsible for any transportation cost. This warranty does not cover consumables and failures due to abuse, misuse, accident or unauthorized alteration or repairs.

--Sound after Sales Service We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

Packaging & Shipping

Exported Package

1. Plastic bag inside and woven bag out side, 620rolls/1x40HQ

2. Plastic bag inside and carton out side, 525ctns/1x40HQ

- Q: Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q: Definition of ceramic fiber

- 1. Definition of ceramic fiber:Ceramic fiber is a fibrous lightweight refractory.2, ceramic fiber expansion:Ceramic fiber, also known as aluminum silicate fiber, is the main component of refractory fiber!HLGX ceramic fiber is the refractory material with the lowest thermal conductivity and the best heat insulation and energy saving effect except the nanometer insulation material. The utility model has the advantages of light weight, high temperature resistance, good heat insulation effect, convenient construction, etc., and is a lining material of high quality industrial furnaces. Ji'nan dragon hot Ceramic Co., Ltd. has HLGX ceramic fiber module, HLGX ceramic fiber blanket and other ceramic fiber products widely used in kiln insulation project, high temperature equipment, pipe insulation.3. The origin of ceramic fiber appellation:First of all we want to know the origin and development of ceramic fiber, ceramic fiber first appeared in 1941, the United States Babu Hancock. Cox Newell company with natural kaolin by the arc furnace melt blown fiber. In 1950s, the ceramic fiber was put into industrialized production. In 60s, a variety of products were developed and used as lining for industrial furnaces.Thus, we know that ceramic fiber originated in the United States, and its name "Ceramic Fiber", literally translated literally "Ceramic - ceramic, Fiber - fiber, combination is" ceramic fiber".

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- (2) the density of Tao Xianzhan is below 200Kg/m3 (generally 160kg / m3), only light heat resistant lining L / 6 - 1/7.(3) the heat capacity is only 1 / 9 of light heat resistant lining and light fireclay bricks.(4) the ceramic fiber is stable in high temperature, the residual shrinkage rate is very small, and it needs no shrinkage or expansion joints, so it is easy to construct.(5) the coefficient of thermal conductivity is small. On the hot surface temperature of 600 degrees Celsius (the average temperature of 366 DEG C) when the orientation coefficient is 0.078W / (M. K); 900 (the average temperature is 551 DEG C) of O.096W / (m.k); 1100 (the average temperature is 678 DEG C) of 0.125W / (m.k), is about light fireclay bricks 1 / 8, for the light at 1 / 10 heat resistant lining.(6) sound insulation effect is good. The ceramic fiber coating can reduce the high-frequency noise with frequency less than 1000Hz, and also absorb some low-frequency noise.(7) it has a certain tensile strength.(8) good chemical stability.(9) good elasticity (78% at normal temperature), easy to transport and install.(10) it has better resistance to airflow erosion, and can withstand 30 - 50m/s airflow erosion.

- Q: The product characteristics of ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;

- Q: The characteristics of ceramic fiber paper

- 1, high strength tear resistant 2, high flexibility 3, low slag ball content 4, accurate thickness 5, thermal shock 6, very low thermal conductivity

- Q: What is the use of ceramic fiber paper?

- 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes). 4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers. 5) non-toxic, harmless and odorless.

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- Soluble ceramic fiber is a new product and biodegradable. Beijing Fei Pufu

Send your message to us

1260C Low Thermal Conductivity Ceramic Fiber Blanket for High Temperature Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords