110lm/W LED 2835 SMD For LED Tubes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 30000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

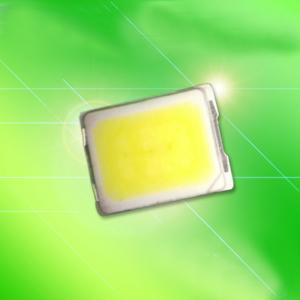

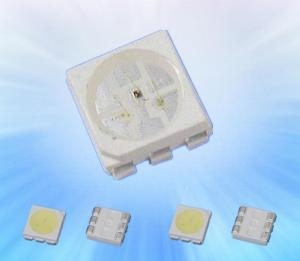

This surface-mount LED comes in standard package dimension.

It has a substrate made up of a molded plastic reflector sitting on top of a bent lead frame.

The die is attached within the reflector cavity and the cavity is encapsulated by silicone.

The package design coupled with careful selection of component materials allow these products to perform with high reliability.

110lm/w LED 2835 & 3528 & 3014 SMD for LED tubes

Model | Color | Item | Lumens | CCT/WLD | Power | Voltage | Pick current | Size | Beam angle | Chip |

SL-WZ2835-CH | white | 2835 smd led | 21-24lm | 5000-7000k | 0.2W | 2.8-3.5V | 60mA | 2.8*3.5*0.8mm | 120° | Epistar |

SL-IZ2835-CH | warm white | 2835 smd led | 21-24lm | 2800-3200k | 0.2W | 2.8-3.5V | 60mA | 2.8*3.5*0.8mm | 120° | Epistar |

SL-WZ3528-AH | white | 3528 smd led | 7.5-8.5lm | 5000-7000K | 0.06W | 2.8-3.5V | 20mA | 3.5*2.8*1.3mm | 120° | Epistar |

SL-IZ3528-AH | warm white | 3528 smd led | 7.5-8.5lm | 2800-3200K | 0.06W | 2.8-3.5V | 20mA | 3.5*2.8*1.3mm | 120° | Epistar |

SL-WZ3014-BH | White | 3014 smd led | 10-12lm | 5000-7000K | 0.1W | 2.8-3.5V | 30mA | 3.0*1.4*1.12mm | 120° | Epistar |

SL-IZ3014-BH | Warm white | 3014 smd led | 10-12lm | 2800-3200K | 0.1W | 2.8-3.5V | 30mA | 3.0*1.4*1.12mm | 120° | Epistar |

Warm white,white,cool white, and single color led are available for you.

CREE chip allowed high current forward and it is available from us.

Features:

1. Emitted Color: White 110lm/w LED 2835 SMD for LED tubes .

CCT: 5000-7000K

Luminous Flux: 21~24lm

Luminous intensity:5500~6000mcd @120 degrees

2. Led Appearance: Yellow diffuse with white face support

3. 2.8x3.5x0.8mm New design package

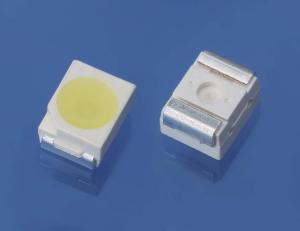

4. Suitable for all SMT assembly methods

5. Compatible with infrared and vapor phase reflow solder process.

6. Compatible with automatic placement equipment

7. This product doesn’t contain restriction Substance, comply ROHS standard.

Main Applications

Indoor illumination,Strip lighting.

Advertising Decoration.

Backlighting: LCDs, Key pads advertising

Automotive: Dashboards, stop lamps turn signals.

Instead of 5050 in normal product application etc.

Advantages

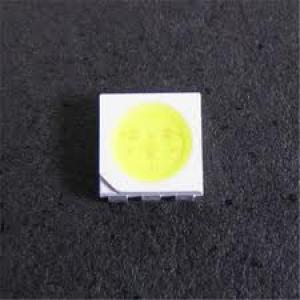

The same structure with 3528 SMD

The size: 2.8*3.5*0.8mm (thin support)With heat sink on the bottom

Withstand more higher current

(20mA-100mA is allowed)Reliability

(Big size of Chimei & Cree chip)The chip: By Epistar or CREE12*20

Easy to design the Circuit.

High efficiency to mount.

Ultrathin support to meet the design of advertising module.

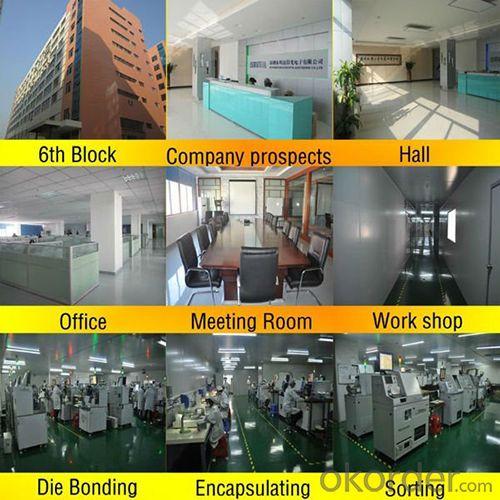

About Us

♦ Experience: we have several years experience of indoor lighting led component.

♦ Good After Sales Services: shipment and sample quality tracking includes lifetime,switch-on/ off time and lumen maintenance. Any small problem happening in our led will be solved at the most prompt time.

We always offer relative technical support/consultant. Quick response,all your inquiry will be replied.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- If you choose the brightness of blue light in the light of the relatively high, so when debugging the white balance (by changing the resistance to change the current, and then change the RGB brightness LED lamp), it is difficult to transfer to the pure white. Therefore, when selecting the lamp, the blue light is generally not bright.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED white is the light emitting diode, a PN junction to the most important use of SMD beads is the heat, according to the different manufacturer beads, glue package is not the same, should pay attention to pre baking time and temperature, the latter should pay attention to the patch temperature, the most important is the price, many manufacturers in order to cost savings, internal chip used is too small does not meet the standards, support steal frugal material, with iron, the failure cycle shortened, LED lamp can not reach the ideal effect. Again, the LED supply current must not exceed the rated value, which is an important factor in damage to lamps and lanterns

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- To package with epoxy SMD beads are used in a lot of outdoor display, because the epoxy adhesive with good adhesion to all better PPI support in outdoor use, our high quality and inexpensive epoxy epoxy call for samples

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: What is the difference between patch LED beads and LED beads: General

- A LED chip is led lamp. Common LED has two or four pins, and there is no needle foot, close to the circuit board, copper foil welding, are the same. You should choose the lamp the key is to consider the color temperature, color rendering index, light efficiency, light, and power quality, buy these things to buy better quality, common is topclass photoelectric

- Q: Which is good for LED patch and LED bulb?

- LED (light emitting diode) patch (package)LED patch (SMD) made by FPC circuit board, LED, high quality silica gel. The waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising - Entertainment decorative lighting lighting field.LED bulbA solid state semiconductor device that converts electric energy into visible light by means of LED (light-emitting diode), which converts electricity directly into light; LED = Large, Electronic, Display,;

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Of course, the reflow soldering is generally divided into three sections of six principle of oven temperature is 150 degrees, 190 degrees, 220 degrees, with a PC lens products can not reflow soldering, PC deformation at 150 degrees, can be heated by a soldering paste on the heating plate.

- Q: How many volts is a single LED on the LED patch band?

- The single LED on the LED patch band is around 3.3V.LED light emitting diode, which is a nonlinear component, its operating voltage (tube pressure drop) is also different: ordinary red LED about 1.5 V; ordinary green LED about 1.8 V; bright white LED up to 3.3 V or so.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

Send your message to us

110lm/W LED 2835 SMD For LED Tubes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 30000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords