1/2 HPL Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Basic Date of HPL Faced Particle Board

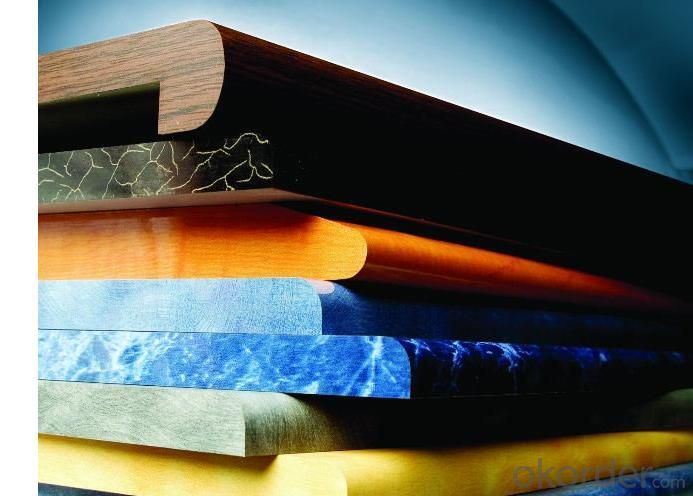

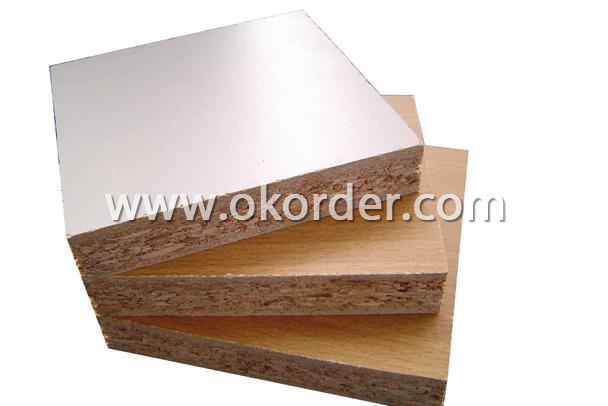

Product Name: HPL faced/laminated particle board (chipboard/flakeboard/shaving board)

Size :1220*2440

Thickness: 9-25mm

Thickness Tolerance: +/-0.2mm

Face/Back: Face is laminated with HPL (high pressure laminate board), back can be laminated with melamine paper or HPL.

2. Specification of HPL Faced Particle Board

|

Technical Parameters |

Moisture Content |

≤8% | |

|

Water Absorption |

≤10% | ||

|

Modulus of Elasticity |

≥2800Mpa | ||

|

Static Bending Strength |

≥25Mpa | ||

|

Surface Bonding Strength |

≥1.50Mpa | ||

|

Internal Bonding Strength |

≥0.80Mpa | ||

|

Screw Holding Ability |

Face |

≥1500N | |

|

Edge |

≥950N | ||

3. Usage & Performance of HPL Faced Partical Board

HPL faced partical board is widely used for table top,countertop, kitchen top, furniture,

cabinet and interio decoration. With good properties, such as, acid & alkali resistant,

heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect.

- Q: What create an excellent condition.

- Many furniture manufacturers have re-use of particleboard as raw materials, in addition, directional particleboard is also gradually accepted by consumers

- Q: Today's demand for wood-based panel products

- which gave the development of China's particleboard industry opportunities The Therefore, China's particleboard consumption is expected to increase year by year.

- Q: What is the modeling technology department?

- In addition, there is a planar molding method in which a pattern is pressed on a surface of a prepared particleboard or a hot-pressed molding slab to form a relief pattern

- Q: Make the raw material of the particleboard

- And then sizing the shavings after the paving slab, the thickness of the finished product is generally 10 to 20 times the thickness

- Q: What factors China's Particleboard industry development obstacles to

- the bark and MDF to produce dust and so on are used as raw materials for particleboard, China's production of particleboard generally poor quality, but also the prevalence of formaldehyde seriously exceeded the problem.

- Q: Raw materials for the production of particleboard include

- Preparation of wood shavings processing equipment are chipper, re-crusher, grinding machine and fiber separator, cutting methods are cutting, cutting and broken.

- Q: Particleboard by product classification

- . In addition, there are non-wood materials such as cotton stalks, linen, bagasse, rice husk and other made of various particleboard,

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- turtle bamboo like green plants, not only can absorb formaldehyde can beautify the environment

- Q: What types of particleboard can be divided into?

- bending strength, vertical plate tensile strength (internal strength), grip nail force elasticity Modulus and modulus, etc

- Q: How to improve the particleboard market space

- enterprises should increase scientific and technological innovation, vigorously recover waste wood, to achieve circular economy

Send your message to us

1/2 HPL Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords