0.2-0.6mm transparent PVC rigid film for pharmaceutical packaging materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The main raw material of PVC solid pharmaceutical rigid film is polyvinyl chloride resin. The surface of this packaging material is smooth, transparent, and uniform in thickness. It is easy to form, easy to seal with PTP aluminum foil, has good oxygen barrier properties and water vapor barrier properties, and the blister is firm after forming, which can provide good support and protection for the contents.

Production process:

A packaging material that meets pharmaceutical requirements is produced by adding certain processing aids to polyvinyl chloride resin through extrusion, calendering and other processing methods.

PVC rigid film specifications:

| Thickness | 0.20-0.60mm |

| Width | 75-1300mm |

| Color | transparent, glass transparent, blue transparent, amber, orange, white, blue, brown, pink, green |

| Transparency | transparent, translucent, opaque |

| Surface | bright and clean |

| Inner diameter | 76/152mm |

| Outer diameter | 200-700mm |

| Application | tablets, packaging capsules, pills, injection trays, blister packaging |

Development prospects:

In domestic PTP aluminum-plastic blister packaging, PVC rigid films account for more than 95%; the foreign trend is also dominated by PVC rigid films, accounting for about 60%, but the growth rate of composite sheets is 3-4 times that of a single material, and is rapidly becoming the mainstream. New materials such as PP, PET, and PS have emerged, but their comprehensive performance and appearance are not as good as PVC.

Advantages of PVC rigid films for pharmaceutical packaging:

1. High transparency: easy to observe the status of the medicine in the package.

2. High barrier properties: blocking moisture, oxygen and other gases, extending the shelf life of drugs.

3. Excellent impact resistance: protect the safety of drugs during transportation.

4. Chemical stability: good resistance to common chemical substances, not easy to react with drugs.

5. Good processability: easy to thermoform, suitable for drug blister packaging production.

6. Non-toxic and sterile: PVC rigid films are produced by calendering process, with non-toxic and sterile characteristics, suitable for drug packaging.

Application areas of medicinal PVC rigid films:

1.Drug blister packaging: blister packaging for solid drugs such as tablets and capsules to extend their shelf life and safety.

2.Liquid drug packaging: such as infusion bags, blood bags, etc., to ensure the sterility and stability of the product.

3.Medical device packaging: protective packaging for medical devices such as syringes and infusion tubes.

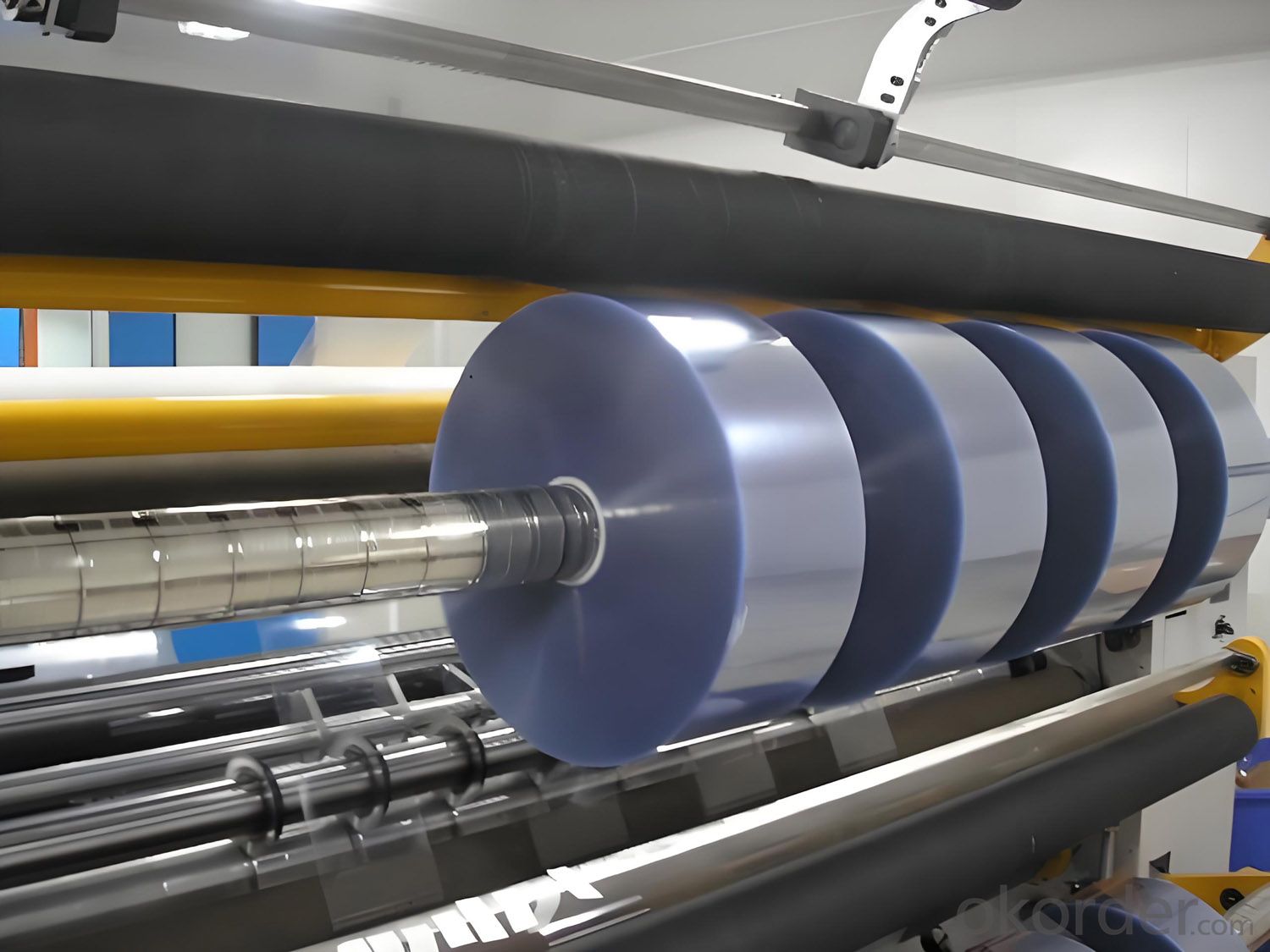

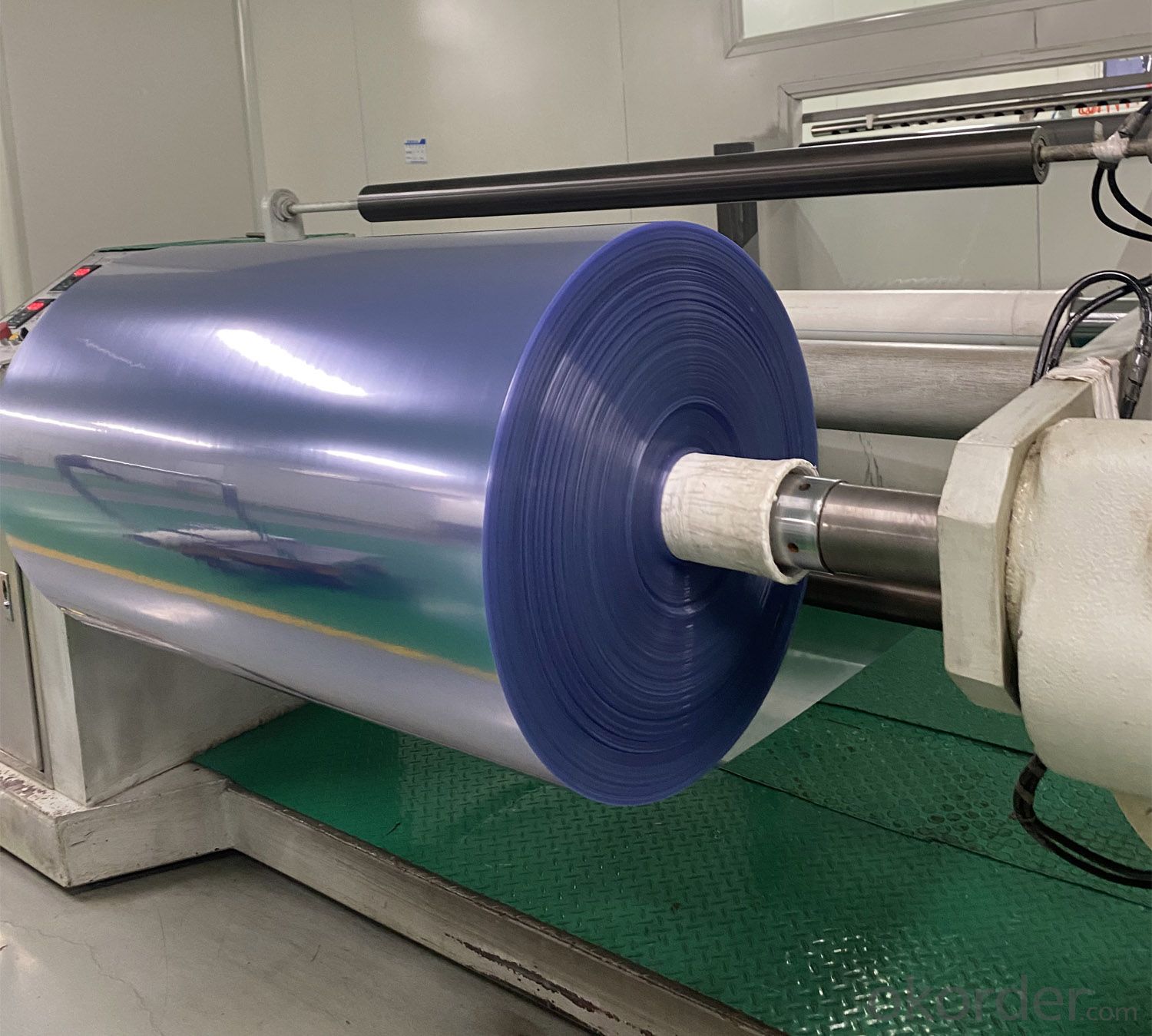

Production workshop:

Production workshop:

We has a domestically technologically advanced six-roller calendering production line and a "D-level" clean production workshop; an annual output of 25,000 tons; selected high-quality imported raw materials, pay attention to every production detail, and provide pharmaceutical companies with the most cost-effective packaging materials.

Package

- Q: What color glass, plastic film or supplementary light source should be chosen for growing vegetables in greenhouse?

- Hello friends, plastic greenhouse planting eggplant fruit vegetables suitable plastic film is EVA film, PO membrane two kinds, PO membrane price is too high, and use the most common or EVA film.EVA film transmittance, high temperature, fast, good insulation, the price is suitable for every square in a piece of five to two blocks between.Others, such as poly vinyl non dripping film, this is to filter UV, affecting the coloring of vegetables. Grouting film is cheap, the disadvantage is that the temperature is too fast, low transmittance, no drop is too short.

- Q: What's the performance of PE plastic film?

- Physical and mechanical properties. The tensile properties of LLDPE and LDPE ratio, tensile quantity, tensile yield strength, especially the tensile strength and elongation at break, generally from the stress-strain curve obtained when the fracture area of the energy required, as the index of rigid resin. Obviously, LLDPE good rigidity, it can be considered as the reason for tethering LLDPE molecule.The relationship between stiffness and density: the lower the density, the worse the rigidity (i.e. softer). For the same density, the impact strength of LLDPE would be better than that of C4, and the impact strength of C6 and C8 copolymer polymers would be higher.The physical and mechanical properties of LDPE films are obviously better than those of LDPE. Their softness, toughness, cold resistance and puncture resistance are better than those of LLDPE films.

- Q: Why do plastic films undergo prepress?

- To gravure printing, flexo printing as a supplement, at present we are mainly gravure printing, gravure printing is absolutely mainstream, but this should be based on the actual situation of the enterprise to choose

- Q: How do you tear the plastic film under your new shoes?

- The new shoes under the plastic film can be directly torn down, and if it is difficult, you can use the blower to the hot air file, blowing for a while, the heat is easy to tear off.

- Q: Plastic film sealing machine (Dorch) repair

- You, I have not seen this model, I do not know is semi-automatic film sealing machine, but also pedal, or hand press?. Pass the picture and see his structure.

- Q: Keyboard circuit board, film paper and rubber strip, how is it installed?

- The rubber strip is pressed on the outside of the film. Generally, the rubber strip is placed on the cover, then the membrane is placed, and then the circuit board is inserted. Then the screw is screwed down to the circuit board, so that it is compressed.

- Q: How to choose PE plastic packing film

- Transmittance and haze are important indexes that determine the visibility and clarity of packaged goods, and have a great influence on the display effects of goods. Transmittance and fog are expressed as percentages. The greater the transmittance, the better the transparency of the film; and the greater the haze, the greater the opacity of the object through the film, the less clarity.

- Q: What's the plastic film on the disposable paper cup?

- At present, the domestic use of disposable cups can be divided into three types: cold, hot drinks and ice cream cup cup cup; according to the use of paper cups, the coating is also divided into three kinds, one is the wax cup, and a cup of polyethylene film and straight wall double cup.

- Q: What are the differences between geotextiles and geomembrane?

- Geotextiles, also known as geotextiles, are synthetic geosynthetics made from synthetic fibers by means of needle or weave. The finished product is in a cloth shape with a width of 4-6 meters and a length of 50-100 meters. Geotextiles are divided into woven geotextile and nonwoven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention and protection. It has light weight, high tensile strength, good permeability, high temperature resistance, cold resistance, aging resistance and corrosion resistance.

- Q: PVC and PE plastic film, which can be used as food preservative film?

- Plastic wrap for food should be made of PE. Cannot use PVC. Because PVC does not meet the requirements of food packaging safety.

Send your message to us

0.2-0.6mm transparent PVC rigid film for pharmaceutical packaging materials

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products