WQ Series Sewage Submersible Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WQ Series Sewage Submersible Centrifugal Pump

Product Description:

1. WQ series Sewage Submersible Pump Introduction details:

WQ series submersible sewage pump is mainly used for municipal work, industrial building, hotels, hospitals, civil air defense, mines, etc. It can be widely used in transfer waste water, rainwater and living water etc. which contains solid grains and various long fibers CNBM WQ series sewage submersible pump have many advantages, such as, hi-efficiency, circumvolution proof, blockage free, auto-coupling, hi-reliability and auto-control, etc.

2. WQ Series Sewage Submersible Pump Operating Conditions details:

1). Rated Voltage: 380V (660V), Frequency: 50Hz, 3-phase AC.

2). Temperature of medium under 40ºC.

3). PH value: 4~10.

4). Volume ratio of solid in medium below 2%.

5). Density of medium should be lower than 12000kg/m³.

3. WQ series Sewage Submersible Pump Technical Performance details:

Discharge diameter: 50~600 mm

Capacity: 10~8000m³/h

Head: 5~60m

Power: 1.5~315kw

Diameter of pass solids: 20~145mm

4. WQ Series Sewage Submersible Pump Structure Characteristics details:

WQ series submersible sewage pump is equipped with status indicator and protection device to ensure for pump safe and reliable operating.

1). the unique cable airproof is adopted, avoid leakage of cable.

2). Heat protector in stator assure of operating life of the motor.

3). The pump adopts outer recycling cooling design with motor power more than 18.5kw, which can keep the pump operating safely under the lowest water level.

4). A floating switch is installed at the bottom of motor chamber to protect the mechanical seal in the motor side.

5). the oil-water probe is installed at the up end of the oil chamber between pump and motor that can protect the mechanical seal in the side. If leakage occurs, the system will signalize and start protection.

6). Adopt perfect mechanical seal, the sealing material adopt tungsten carbide, silicon carbide and hard metal alloy, which can prevent the water from entering into the motor, and keep the operating reliable and safety.

7). the auxiliary impeller can balance the pressure outside of the mechanical seal, prevent the water entering into the oil chamber and prolong the life of the motor.

8). Unique impeller design, wide passage allow large solid and long fiber passing through freely, it features non-clog, convolve-proof and good passing ability.

9). the changeable wearing ring is installed between the impeller and the volute to keep the optimum operation conditions.

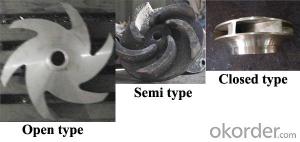

5. Impeller Designs Details of Sewage Pumps:

For the sewage to pass freely, it must be widen the flowing passage of impeller, for the big pump, can used for double-vane, or three-vane, for the small pump, it used for single(double) flowing passage, like a bent pipe has same section, it has a good passing characteristic, avoid stop, convolve caused by slowing current possibly. The especially flowing passage of impeller, cooperate with logical volute, made the paper, soft goods, garbage bag and other material in sewage can passing freely and the pump have no vibration in the course of running-in and load through the impeller balance between dynamic and static state.

6. FAQ regarding WQ Series Sewage Submersible Centrifugal Pumps:

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q: About 3 weeks ago our water stopped. We replaced the switch at the pump and it was fine. Today when I was running water, it stopped again. I went and flipped the breaker on it, but it still didn't come on. About 20 minutes later, it started working again. Have you ever had this happen or do you know what the problem could be?

- Sounds like its overheating. There is a fuse that will automatically shut off if it gets to hot.

- Q: Where is the water pump located on a 1993 mitsubishi eclipse with a 1.8 motor

- Your water pump would be located on the right hand side of the motor. It has the fan belt running on the pulley in front of it the top water hose is connected to it. I hope this has helped you out.

- Q: i installed a new pump don't know how to increase water pressure and to what what pressure it should be set

- This is very simple i would sugest the pressure to be set betwene 60 to 70 NO MORE THAN 70. 1. turn off power to pump (ether the circut breaker or a switch near the pressure switch) you dont want to weld the wrench to the switch. 2. remove the cover to the pressure switch its self (usly one #2 phillips screw) 3. now you will see 4 wires under some sloted screws nearest to the front of the switch, behint that is 1 or 2 bolts with a spring and a nut. 4. if you see 2 bolts you will want to turn the nut on the larger one to the right. you will want to tighten it about 1 to 2 full turns. (the same goes if there is only one bolt also) 5. now open the valve that is on the tank untill you here the switch click. then close the valve. 6. turn the power back on tio the pump and watch the pressure gauge on the tank. i DO NOT RECOMEND MORE THAN 70PSI. 7. if it goes over the pressure you want repete steps above exept loosen the nut in about 1/4 to 1/2 turns untill you reach the desired pressure 8. if it does not reach your desired pressure then you do the same thing exept tighten the nut in 1/4 to 1/2 turns untill you attain your desired pressure. 9. when the pressure is reached, replace cover so you dont risk rusting the contacts. if you need more help feel free to email me. and i will assist you in any way that i can.

- Q: Fire pump room is required to set up water pump control room?

- What is the concept of fire pump control room? If there is a control room host automatic alarm automatic fire alarm system of words (through the pump distribution box can also control) can control the fire pump, if there is no distribution box automatic alarm system you can through the pump room control

- Q: 30kW what is the flow rate of the pump?

- Estimated traffic: Q = nP/ (9.8H), =70%*30/ (9.8H), =2.14/H (m^3/s)It is estimated that the efficiency of the water pump unit n=70%, power P to kW as a unit, the head H to m as a unit, you go to check the head H is how many meters, into the formula can be considered the flow rate is how many cubic meters per second.

- Q: Is it a must to change the entire water pump since only driplets of anti-freeze leak out over a 7day period from the bottom of the pump? Can i simply change the gasket and make it all better? Water pump is pumping and making no noise, vehicle isnt over heating.

- your water weep hole is on bottom of water pump also.if its the water pump weep hole leaking.that signs of water pump shaft bearing is going bad.water pump needs replacing.

- Q: I am replacing the water pump and want to know exactly where the two o-rings go

- There are several rubber seals on a water pump. The biggest irregular shaped seal is obviously for the main portion of the pump (this can not be misinterpreted for something else). The next in size is the o-ring for the thermostat. And 2 additional O-rings (one smaller than the other) are for the return pipes. While removing/pulling out the pump, take care that the pipes do not get pulled outward by the pump. And when putting in the pump just gingerly align the pipes to the holes in the pump and you are good to go.

- Q: Our watrer pump on our well will constantly prime itself when we use the water in our house.As you are running the tap the water will gain pressure on and off like someone is using another tap in the house. Any suggestions?THanks in advacne

- How old is the Pump ? Could the Impeller be worn out ? Is there a replaceable filter ? Could it possibly be stopped up ? Are there any leaks in the pipe leading from the well ? Is there a way that you could measure the current being drawn by the pump, with an Amp Meter, to determine if it's pulling more Current than it should be ? Until these questions are answered, it's probably just going to be a guessing game.

- Q: What is the reason that the water supply of pump is getting smaller?

- 1, the water pump screen plug, should remove the filter screen sundries.2, the use of lift is too high. Over the pump range, the pump should be adjusted to use height or replace the pump head.3, pump impeller plug or wear, should remove the impeller sundry. Replace the impeller if worn.4, pump outlet pipe blocked by debris, should remove the debris in the pipe outlet.5, diameter and pump does not match, replace the outlet pipe.6, the pump cover gap is too large, increased pump volume loss, should adjust the gap.7, pump body and pump cover leakage, should tighten the pump cover screw, make the pump body and pump cover close coordination.8, the pump speed is low, the use of voltage is too low. Should adjust the voltage to the rated value, replace the thicker cable or avoid peak use.9, water pump diving depth is too shallow, there is air intake, should adjust the diving depth. Pump running depth is not less than 0.5 meters.Yi Mai water pump to help you answer, I hope to help you

- Q: Water is leaking from the front of my car, on the right where the radiator is located. only thing is that its not leaking a lot, just a little.... but people keep telling me that my timing belt is going to go out and that i will be stranded!. i will like to know the cost of both the water pump and timing belts for my 2001 PT Cruiser please.

- Pt Cruiser Water Pump

Send your message to us

WQ Series Sewage Submersible Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords